The Use of Artificial Muscles in Robotics: Bringing Robots Closer to Humans

You're seeing a revolution in robotics with artificial muscles making robots more human-like in function and interaction. These biomimetic designs let robots mimic human limb movements precisely, thanks to actuation mechanisms and bioinspired control systems. Using flexible, electroactive materials, these artificial muscles move with smooth, natural motion. In healthcare, they improve rehabilitation devices and surgical robots, while in manufacturing, they increase efficiency and flexibility. Yet, challenges like energy demands and cost impact their feasibility. But innovations promise even closer mimicry of human muscle function. There's much more to uncover about how these developments will reshape robotics.

Evolution of Robotic Muscles

The evolution of robotic muscles has been a game-changer in the field of robotics, transforming how machines mimic human movement. By embracing biomimetic design, these artificial muscles enable robots to replicate the complex motions of human limbs with remarkable precision. Thanks to advancements in soft robotics, these innovations utilize flexible, responsive materials that allow for smoother and more natural movements.

Your understanding of control strategies is essential when working with robotic muscles, as they guarantee that the machines operate efficiently and effectively. These strategies are tightly integrated with energy efficiency, optimizing the power usage of robotic systems and extending their operational lifespan. The multi-functionality of these muscles also improves a robot's ability to perform a range of tasks, from delicate object manipulation to robust lifting.

Sensory integration is another important aspect, providing feedback that allows robotic muscles to adjust in real-time to changing environments. This sensory insight is critical for maintaining balance and precision. Different actuation methods, such as pneumatic, hydraulic, or electroactive polymers, are employed to achieve desired movements. By utilizing these technologies, you can create robots capable of dynamic and adaptive interactions, pushing the boundaries of what's possible.

How Artificial Muscles Work

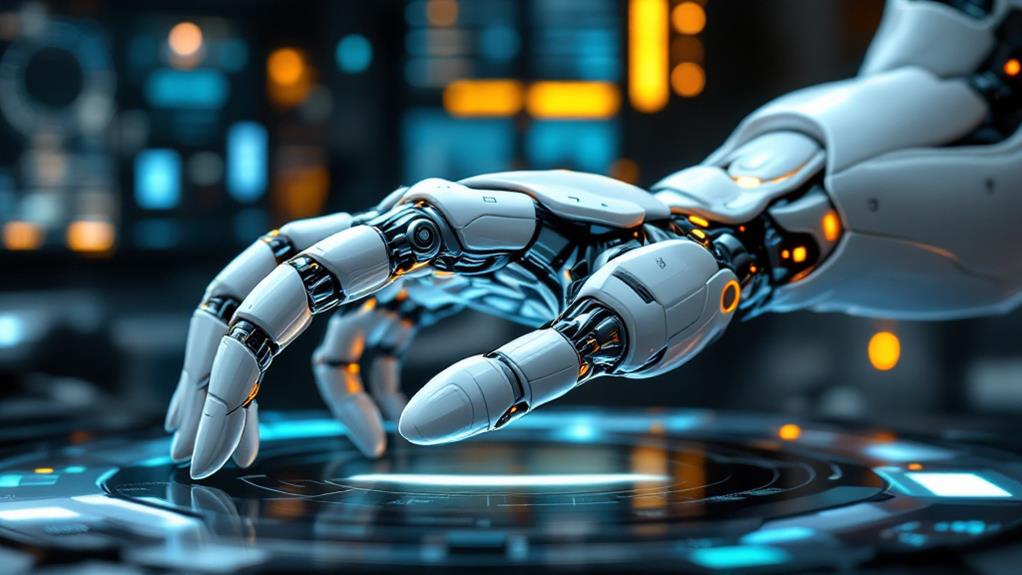

Understanding how artificial muscles work is vital to releasing their full potential in robotics. At the core, artificial muscles operate through actuation mechanisms that mimic natural muscle movements. These mechanisms are the driving force, converting energy into mechanical motion. To achieve energy efficiency, you need to guarantee that the energy input is optimized for performance, reducing waste and prolonging the muscle's operational life. Control systems play a significant role by precisely managing these movements, adjusting the actuation for smooth, coordinated actions.

Bioinspired designs guide the development of artificial muscles, modeling them after human muscles for improved functionality. Performance metrics are fundamental—they help you gauge how well these muscles meet speed, force, and responsiveness requirements. Material durability is another important factor, as the materials must withstand repetitive cycles without degrading.

To integrate artificial muscles successfully into robotic systems, you should focus on effective integration techniques, making sure that they work harmoniously with existing components. Sensory feedback systems can elevate the robot's ability to respond to its environment, providing real-time data to adjust movements.

Here's a quick rundown of these concepts:

- Actuation Mechanisms: Convert energy into motion.

- Control Systems: Manage muscle movements precisely.

- Integration Techniques: Guarantee seamless operation with other components.

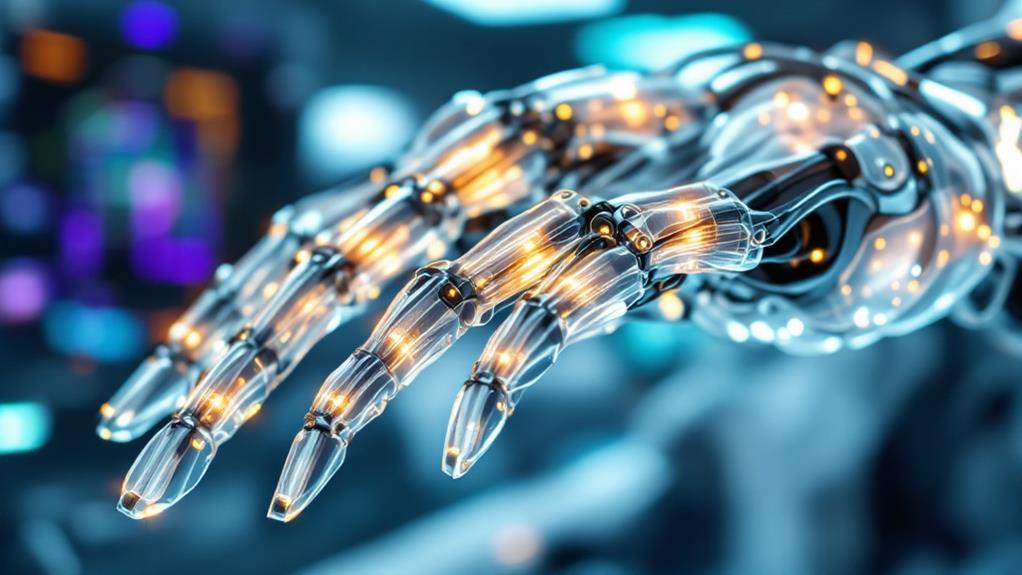

Materials Used in Artificial Muscles

Choosing the right materials for artificial muscles is fundamental to their performance and longevity. You'll find that polymers research plays a significant role in identifying suitable materials for these muscles. Electroactive materials, such as dielectric elastomers and conductive polymers, are popular choices because of their ability to change shape or size when stimulated electrically. These materials directly impact the actuation mechanisms, which dictate how effectively an artificial muscle can mimic natural movements.

When selecting materials, you should consider performance metrics like energy efficiency and response time. Energy-efficient materials guarantee that the artificial muscles require minimal power to function, making them practical for real-world applications. Durability testing is also critical, as it assesses how well these materials withstand repeated use without degrading. You'll want to focus on options that not only endure diverse stresses but also maintain their functionality over time.

Biocompatible options are particularly significant if the artificial muscles will interact with human tissues. Scalability issues should also be on your radar, as the materials you choose need to be produced cost-effectively on a large scale. By addressing these considerations, you're setting the stage for creating high-performing, long-lasting artificial muscles.

Applications in Healthcare Robotics

With the right materials in hand, artificial muscles are transforming healthcare robotics, promising improved patient care and rehabilitation. You can see these advancements in different applications. For instance, rehabilitation devices are now more effective thanks to artificial muscles, helping patients regain strength and mobility more efficiently. Surgical robots equipped with these muscles perform delicate procedures with precision, improving outcomes and reducing recovery times.

Artificial muscles are also making assistive technologies like prosthetic limbs more lifelike and functional. These limbs provide users with better control and mimic natural movements, greatly enhancing their quality of life. In telemedicine applications, artificial muscles enable remote surgery, allowing specialists to operate on patients from afar with remarkable accuracy.

Additionally, patient monitoring and mobility aids benefit from artificial muscles, offering real-time data and support to those in need. Here's a breakdown of how these innovations are applied:

- Rehabilitation Devices: Improve physical therapy equipment to enhance patient recovery.

- Surgical Robots: Perform complex surgeries with precision and minimal invasiveness.

- Assistive Technologies: Boost prosthetic limbs and mobility aids for daily use.

Embracing these technologies can revolutionize patient care, making healthcare more accessible and efficient.

Impact on Manufacturing Efficiency

In the domain of manufacturing, artificial muscles are driving efficiency to new heights. Imagine your production line operating at lightning speed, thanks to automation advantages that artificial muscles bring. By integrating these advanced technologies with your workforce, you're not just increasing productivity gains but also achieving impressive cost reduction. You'll notice how artificial muscles improve flexibility, allowing your machines to adapt quickly to changes in production demand.

Your team can experience skill improvement as they learn to work alongside these robotic systems, which opens doors to more creative manufacturing processes. With artificial muscles, robots can mimic human-like movements, enhancing production speed and ensuring tasks are completed faster and with greater precision. This means you're optimizing resources by utilizing less energy and reducing material waste, ultimately leading to a more sustainable operation.

Incorporating artificial muscles into your manufacturing processes transforms how you view efficiency. It's not just about doing things faster—it's about doing them smarter. As you adopt these advancements, you're setting the stage for a future where human and machine collaboration leads to unprecedented levels of productivity and creativity. Your manufacturing process stands to benefit immensely from this technological leap.

Enhancements in Service Robots

Transforming service robots has never been more critical, and artificial muscles are at the forefront of this transformation. You can see these advancements in the way robots now mimic human movements more precisely. This increased robotic dexterity means service robots can perform tasks with greater accuracy and fluidity, making them incredibly valuable in fields like healthcare and hospitality.

Artificial muscles enable robots to interact more naturally with humans. The flexibility and responsiveness of these muscles mean that robots can handle delicate objects or assist individuals with greater ease. You'll notice that human-robot interaction becomes smoother, allowing robots to integrate seamlessly into daily life.

Here's how artificial muscles improve service robots:

- Improved Dexterity: Robots can now perform complex tasks, such as folding laundry or serving drinks, with human-like finesse.

- Enhanced Adaptability: Service robots can adjust their grip and force based on the task, reducing the risk of damage or injury.

- Better Interaction: These robots can respond to human gestures and commands more naturally, improving cooperation and communication.

With these improvements, service robots are becoming more efficient and user-friendly, bringing us closer to a world where robots are integral companions in our everyday lives.

Challenges and Limitations

While artificial muscles revolutionize service robots, they also come with their own set of challenges and limitations. You'll notice that performance constraints can be a significant issue. Artificial muscles may not yet match the strength and precision of their biological counterparts, which could limit their effectiveness in demanding tasks. Energy efficiency is another major concern. These muscles often require significant power to function, which can lead to frequent recharging or larger power supplies, complicating their use in portable robots.

Cost implications can't be ignored either. Developing and manufacturing artificial muscles can be expensive, which might make them less attractive for widespread commercial use. Integration challenges arise when trying to incorporate these muscles into existing robotic systems. It's not always straightforward to replace traditional actuators with artificial muscles, and doing so often requires redesigning the entire system.

Durability issues can also affect the longevity and reliability of robots. Artificial muscles might wear out faster than traditional components, leading to increased maintenance. Scalability concerns make it tough to adapt these technologies for larger or smaller robots. Finally, achieving effective sensory feedback is essential for precise control but remains an area needing further development.

Future Developments and Innovations

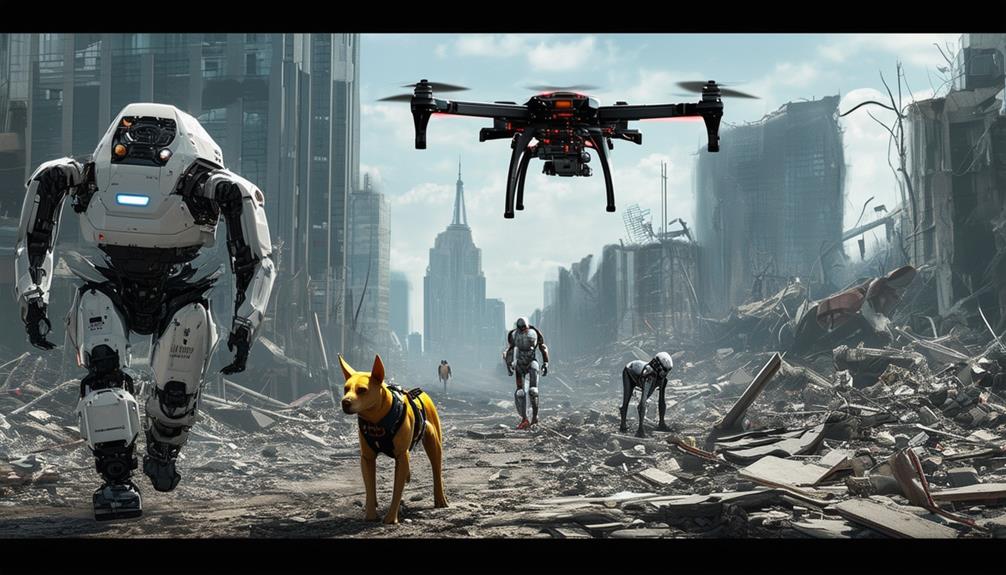

The horizon of possibilities for artificial muscles in robotics is expanding rapidly. As you investigate future developments and innovations, you'll find that several exciting areas are emerging. These include advancements in soft robotics, which allow robots to interact more naturally with their environments. Bionic improvements are also gaining traction, providing robots with enhanced capabilities that mimic human muscle functions. With adaptive systems, robots can adjust to different tasks and environments, offering greater versatility and efficiency.

Consider these three key areas of development:

- Energy Efficiency: Future artificial muscles will likely prioritize energy efficiency, reducing power consumption while boosting performance. This will make robots more sustainable and capable of longer operating cycles.

- Neuromorphic Design and Sensory Feedback: By integrating neuromorphic designs, robots can process sensory feedback more like the human nervous system, enabling more sophisticated and intelligent control of movements.

- Biomechanical Integration: Improved biomechanical integration will guarantee that artificial muscles work seamlessly with robotic structures, enhancing their effectiveness in diverse applications.

As you look ahead, these innovations promise to revolutionize robotics, making them more efficient, responsive, and human-like in their capabilities. Accept the potential of these technologies to transform the future of robotics.

Ethical Considerations in Robotics

As you investigate the remarkable advancements in artificial muscles within robotics, it's significant to recognize the ethical implications accompanying these innovations. With robots mimicking human actions more closely, the notion of robotic empathy becomes a critical discussion. How do you guarantee machines understand human emotions without crossing moral boundaries? The line between human robot interaction and autonomy can blur, raising concerns about robots making autonomous decisions that might not align with societal values.

You must consider the social acceptance of robots in everyday life. Will people feel comfortable with machines that appear too human-like, or will it evoke fear and resistance? Developing thorough regulatory frameworks is crucial to address these concerns, guaranteeing that robots operate within ethical boundaries and maintain public trust.

Privacy concerns also loom large. As robots integrate into personal spaces, safeguarding individual privacy becomes paramount. Who's accountable if a robot misuses data or acts unpredictably? These accountability issues demand clear policies and responsible design. Striking a balance between innovation and ethics will shape the future of robotics, guaranteeing that as technology evolves, it aligns with humanity's best interests and moral values.