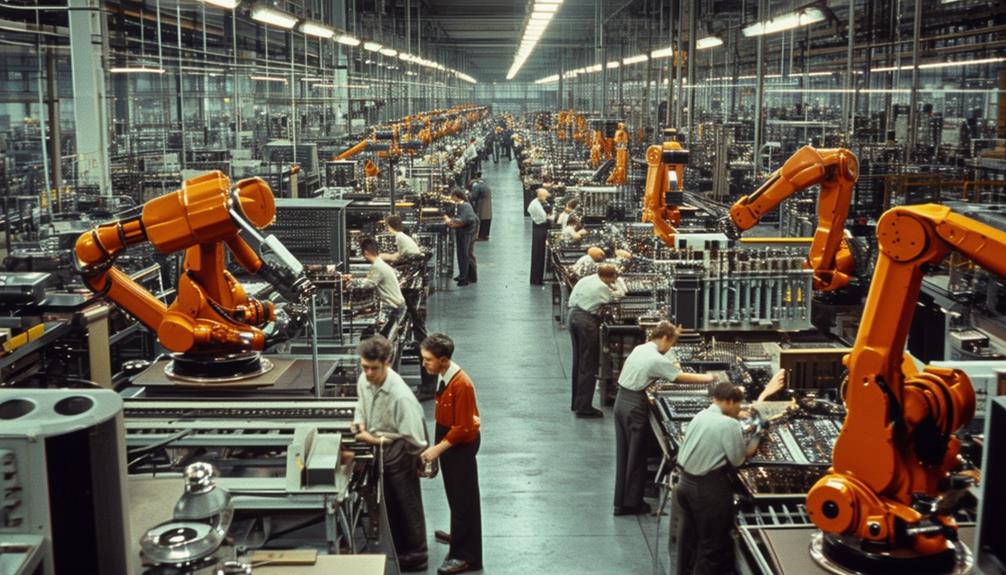

The Evolution of Industrial Robots in Manufacturing During the 1970s

The 1970s marked a period of significant transformation and innovation in manufacturing, driven by advancements in industrial robotics. During this decade, robots evolved from handling simple, repetitive tasks to executing more complex and precise operations. The integration of advanced sensors enabled these robots to take on hazardous tasks such as arc welding and painting. These early innovations in robotic technology laid the groundwork for the sophisticated manufacturing processes we see today. So, what triggered these advancements, and how did they reshape the industry?

Rise of Industry 3.0

In the 1970s, Industry 3.0 began transforming manufacturing by integrating IT and computer technology, marking a pivotal shift towards automation. Industrial robots emerged capable of performing complex tasks with precision and consistency, leading to automated decision-making processes that enhanced factory efficiency and productivity.

The adoption of computer technology streamlined manufacturing processes, reducing the need for manual intervention and fostering consistent, reliable production. This era also saw the inception of cyber-physical systems, which combined digital and physical components to enable real-time monitoring and adjustments, optimizing production lines.

Industry 3.0 fundamentally altered manufacturing approaches, achieving higher output with less effort and fewer errors. Consequently, manufacturing plant productivity soared, setting new standards for industrial efficiency and paving the way for future advancements in Industry 4.0.

Early Robotic Technologies

In the 1970s, industrial robots evolved from performing simple heavy lifting to executing intricate tasks like welding and painting, revolutionizing manufacturing processes. This shift marked the transition from brute strength to precision work, essential for materials handling and hazardous operations. Consequently, the automation of these tasks significantly enhanced production speed and quality control.

The introduction of advanced sensors during this period improved the accuracy of industrial robots, enabling them to perform complex tasks more efficiently. Early machine vision systems allowed robots to 'see' and adapt to their environment, making them indispensable in various manufacturing processes. Robots were no longer limited to moving heavy objects; they could now handle detailed tasks like arc welding and painting with remarkable precision.

Robotic technologies of the 1970s played a crucial role in automating operations that were either too dangerous or too delicate for human workers. By taking on these tasks, robots not only improved safety but also set new standards in accuracy and reliability. This era marked a significant leap towards the sophisticated, multi-functional industrial robots prevalent in today's manufacturing landscape.

Key Innovations

In the 1970s, several groundbreaking innovations propelled industrial robotics into more sophisticated and versatile roles in manufacturing. These advancements significantly enhanced robots' capabilities in precision work and materials handling, enabling them to perform complex tasks with greater accuracy and efficiency.

Key innovations from the 1970s include:

- Advanced Precision Work: Robots were developed to handle intricate tasks with high accuracy, such as arc welding and painting. This focus on precision allowed robots to undertake operations that were previously challenging for automated systems.

- Materials Handling: Innovations in materials handling enabled robots to safely and efficiently manage hazardous tasks, significantly improving workplace safety by reducing human exposure to dangerous conditions.

- Complex Tasks: By the late 1970s, industrial robots had evolved to execute more sophisticated applications, managing detailed and varied tasks. This growth paved the way for future innovations in robotics.

These key innovations during the 1970s established a foundation for the continued evolution of industrial robots, enhancing their role in the manufacturing sector.

Impact on Manufacturing

The integration of industrial robots in the 1970s revolutionized the manufacturing landscape, driving significant advancements in efficiency and safety. This period marked a pivotal turning point as robots enhanced manufacturing efficiency and productivity by performing tasks such as painting, arc welding, and handling hazardous materials with remarkable speed and precision. By taking on these roles, robots not only increased productivity but also substantially reduced production costs.

Workplace safety saw notable improvements as industrial robots assumed dangerous and repetitive operations. Tasks involving hazardous materials or requiring high precision and consistency were now managed by machines, significantly lowering the risk of injury to human workers. This shift enabled manufacturers to uphold stringent safety standards while pushing the boundaries of what could be achieved in the industry.

The 1970s highlighted the transformative power of industrial robots, demonstrating their indispensability in executing a wide range of tasks with unparalleled precision. These advancements set a new benchmark for efficiency and safety, cementing the role of robotics as a game-changer in manufacturing.

Legacy and Future Influence

The innovations in industrial robotics from the 1970s continue to shape the current manufacturing landscape, driving advancements in technology and efficiency. These early robots set the stage for modern systems, incorporating sophisticated sensors and machine vision to perform tasks with precision and speed. This legacy has laid a strong foundation for intelligent decision-making capabilities in today's robots, making them more autonomous and efficient.

Modern robotics owes much to these 1970s developments, particularly in integrating advanced technologies. The groundwork set during that era allows for the seamless incorporation of new innovations, making today's robots far more versatile and capable than their predecessors.

Here are three key areas where this influence is evident:

- Sensors and Machine Vision: Early robots lacked the advanced sensors and vision systems we now take for granted. However, the groundwork laid in the 1970s has led to significant advancements in these areas.

- Intelligent Decision-Making: The basic decision-making capabilities of 1970s robots have evolved into highly advanced algorithms, enabling robots to make complex decisions in real-time.

- Technological Integration: The 1970s marked the beginning of integrating cutting-edge technologies, which has become vital for the multi-faceted robots used in manufacturing today.

Conclusion

The 1970s marked a pivotal era for industrial robots, transforming them from rudimentary machines into precision tools that revolutionized manufacturing. Equipped with advanced sensors and the capability to handle hazardous tasks, these robots laid the groundwork for subsequent innovations. This period did more than just enhance efficiency; it set the stage for Industry 4.0, where even more sophisticated technologies continue to evolve. The advancements from this era continue to influence today's cutting-edge manufacturing processes, ensuring their relevance and reliability.