Pioneers in Robotics: The Impact of George Devol and Unimate

George Devol transformed the robotics landscape with his invention, Unimate. By creating the initial industrial robot in the early 1950s, he changed the manufacturing processes. Unimate efficiently performed repetitive tasks, drove down costs, and increased precision, directly impacting productivity. This innovation laid the groundwork for modern automation, enhancing workplace safety and allowing humans to focus on more complex roles. Devol's work sparked discussions about the ethics of automation and job displacement, shaping the future of robotics. If you're curious about how these changes continue to unfold, you'll uncover even more intriguing developments in the field of robotics.

George Devol's Early Life

Growing up in New England, George Devol was always fascinated by machinery and invention. His family background played a vital role in shaping his early interests. With a father who was an inventor and a mother who encouraged creativity, you could say that innovation ran in his veins. As a child, George spent countless hours tinkering with gadgets, nurturing his curiosity and honing his skills.

His educational path began at a local high school, where he excelled in subjects like math and science. These early academic experiences fueled his desire to investigate technology further. Childhood influences, such as visits to factories and workshops, ignited his passion for engineering and invention. You might say these experiences set the stage for his career beginnings.

As he grew older, George found himself increasingly inspired by the technological advancements of his time. The rapid industrial changes sparked his imagination, pushing him to dream of a future where machines could improve human capabilities. This drive led him to pursue different projects, laying the groundwork for a career that would ultimately change the landscape of robotics forever.

The Birth of Unimate

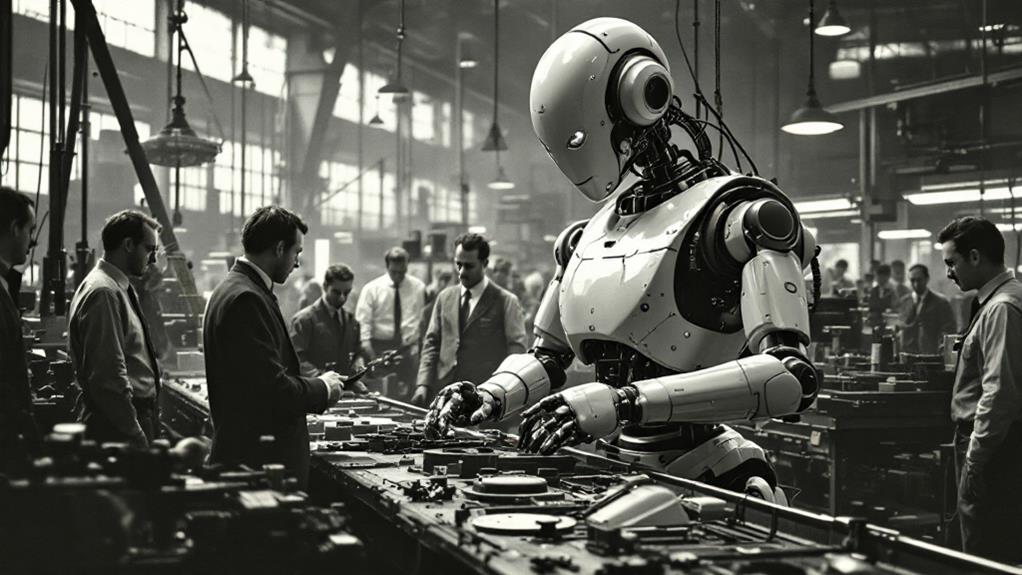

Inspired by his early fascination with machinery and the potential for innovation, George Devol set out to create a revolutionary machine that would change the manufacturing landscape. This led to the birth of Unimate, the world's initial industrial robot. Devol envisioned a device that could replicate human tasks with precision, thereby ushering in a new age in automation history.

In the early 1950s, he developed the necessary technology, which included a programmable arm capable of performing repetitive tasks. This marked a significant milestone in the robotic evolution, as it laid the groundwork for future advancements in robotics. Devol's invention wasn't just a mechanical arm; it was a sophisticated system that could be programmed to perform different functions, highlighting the potential for machines to improve productivity.

After years of persistence and collaboration with engineers, Unimate was ultimately born. The prototype showcased its ability to handle materials, weld, and assemble parts, demonstrating its versatility. This groundbreaking work not only set the stage for the automation of manufacturing processes but also inspired a generation of engineers and innovators to investigate the possibilities of robotics, forever changing the industrial landscape.

Unimate's Industrial Applications

Unimate's industrial applications transformed manufacturing processes across multiple sectors. By integrating this groundbreaking robot into production lines, you can markedly increase manufacturing efficiency. With its ability to perform repetitive tasks with unmatched task precision, Unimate improves production speed while minimizing human error.

You'll quickly notice the automation benefits, as Unimate takes on labor replacement roles that free up your workforce for more complex tasks. This shift not only improves productivity but also leads to considerable cost reduction. As operational reliability becomes a hallmark of your manufacturing process, you'll find that Unimate consistently meets production demands without the fatigue that affects human workers.

Moreover, integrating Unimate contributes to improved workplace safety. By handling hazardous tasks, it reduces the risk of accidents and injuries, creating a safer environment for your employees. As you adopt these advancements, you'll appreciate how Unimate revolutionizes traditional manufacturing methods, allowing you to stay competitive in a rapidly evolving market. The impact of Unimate is clear: it's not just about replacing human labor; it's about improving the entire production process for the better.

Challenges and Innovations

Charting the landscape of robotics presents both challenges and innovations that can reshape industries. As you explore this dynamic field, you'll encounter different robotic hurdles that professionals must overcome. However, embracing these challenges often leads to remarkable technological breakthroughs.

- Increased integration of AI for smarter robots

- Improved safety protocols for human-robot collaboration

- Development of adaptive robots for varied tasks

- Cost reduction in manufacturing and deployment

Each of these innovations propels the industry forward, but they don't come without obstacles. You might face issues like high initial costs, resistance to change from the workforce, or the need for new regulatory frameworks. Yet, tackling these robotic hurdles encourages a culture of continuous improvement.

Legacy of George Devol

The evolution of robotics owes much to pioneers like George Devol, whose groundbreaking work laid the foundation for modern automation. Devol's invention of the initial industrial robot, Unimate, transformed manufacturing processes and set a precedent for a robotic workforce that many industries rely on today. By introducing programmable automation, he not only increased productivity but also sparked discussions around automation ethics.

As you reflect on Devol's legacy, consider how his innovations have led to both opportunities and challenges in the workplace. The integration of robots into numerous sectors has raised significant questions about job displacement and ethical considerations surrounding automation. While robots improve efficiency and take on dangerous tasks, they also demand a reevaluation of workforce dynamics and the responsibilities of companies toward their employees.

Devol's foresight into the potential of machines to perform human tasks has paved the way for ongoing advancements in robotics. His contributions remind you that as technology evolves, so must the conversation around how to ethically implement these innovations in society. Ultimately, George Devol's legacy continues to influence not just technology, but also the ethical frameworks guiding the future of automation.

Future of Robotics and Automation

As we look ahead, the future of robotics and automation promises to reshape industries in profound ways. You'll witness a seamless integration of artificial intelligence, enhancing efficiency and precision across diverse sectors. This evolution isn't just about replacing jobs; it's about workforce transformation, enabling you to focus on higher-value tasks that require creativity and critical thinking.

Consider the following trends:

- Smart factories equipped with AI-driven robots that optimize production.

- Autonomous vehicles transforming transportation and logistics.

- Collaborative robots (cobots) working alongside humans, enhancing productivity.

- AI-powered analytics that provide insights for better decision-making.

These advancements will redefine how you work and interact with technology. As robots take over routine tasks, the demand for skilled workers who can manage and collaborate with these machines will skyrocket. Embracing this change means adapting to new roles and responsibilities, ensuring that you remain relevant in a constantly changing job market. The future isn't just about robotics; it's about harnessing innovation to create a more dynamic and efficient world, where human potential can truly shine alongside intelligent machines.