The advancement of robotics technology allows us to reimagine the many possibilities in different industries. In consumer buying, many robotics inventions have taken place on how Consumer Packaged Goods (CPG) companies bundle or prepare their foods. Interestingly, the market has seen how the non-automotive sector overpowered orders for automotive applications in North America.

The Association for Advancing Automation said that sales of robotic units in North America jumped to 3.5 percent in 2020 compared from 2019. For Q4-2020, robot sales jumped to 63.6 percent over Q4-2019.

In food and beverage, year-over-year orders of robots increased by 56 percent, according to Anne Marie Mohan of Packaging World.

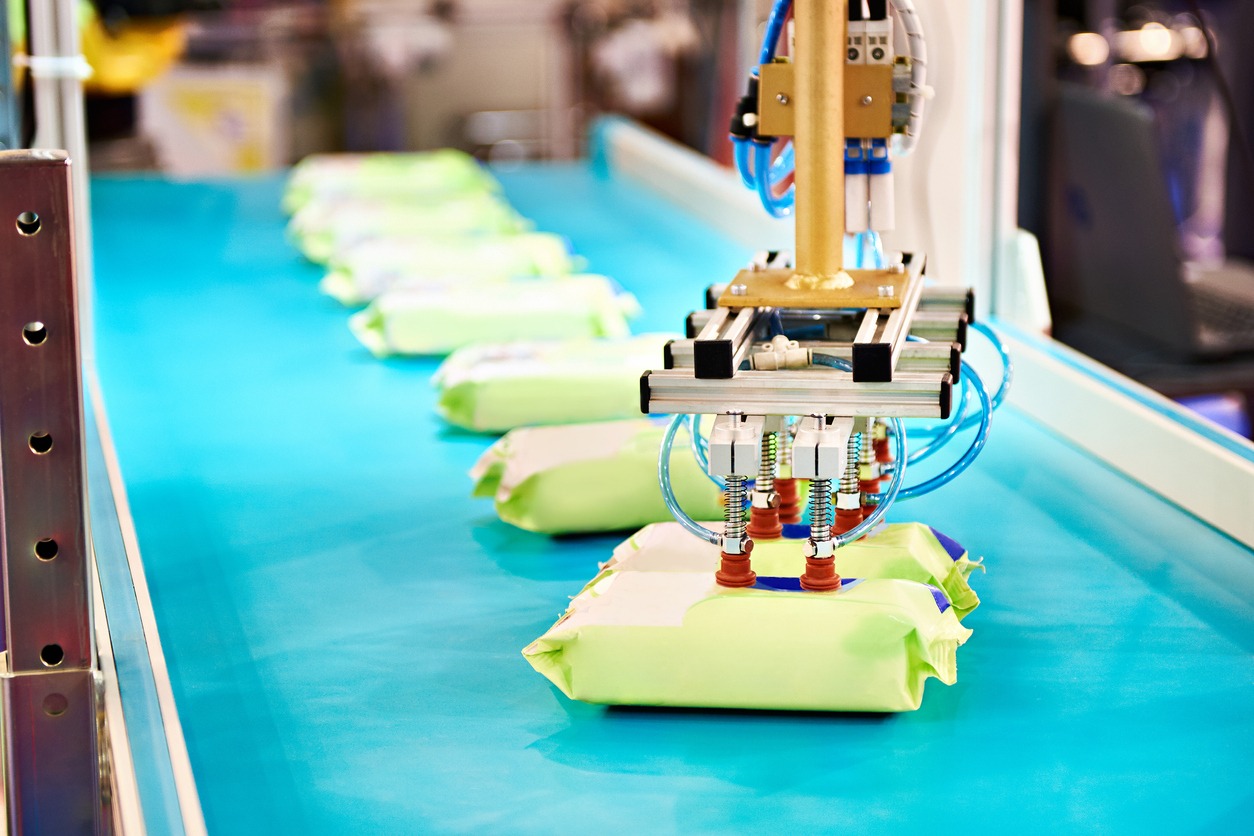

The sudden surge of consumer buying resulted in various innovations in packaging food with less human interventions.

“To meet CPGs’ greater desire for automation, robotics suppliers have been busy innovating,” said Mohan.

“Over the past year, they have introduced robots that are more flexible and can handle a greater variety of applications; more-complex vision systems; robot software and programming that’s easier for newcomers to the technology; and end-of-arm tooling that handles a greater variety of products and offers faster changeover,” she added.

Some of the robotics developments that center on packaging foods with potential impact include the delta, cobots, articulated-arm, SCARA robots, cobots, end-of-arm tooling, and other technology designed for e-commerce:

“Robots have been used in many industries for decades, but they are finally being utilized in food processing. The versatility of robots takes the human element from dangerous areas, such as food processing lines and their use makes the food supply safer,” said Len Calderone for Robotics Tomorrow.

Scientists and industry leaders have seen the ultimate goal of developing robotic technology and Artificial Intelligence on packaging goods without a human touch due to the booming e-commerce, a drop in workforce supply, and the growing demand for pantry stocking.

The robotics technology on packaging goods covers different kinds of applications. These include robotics in food processing from the meat industry, cheese production, baking, frozen, beverage, confection, and produce industries.

“Working in a freezer or refrigerated storage boxes is not conducive to humans, but robots can work in such places without ever needing a break. Cutting and trimming carcasses can be very dangerous work, where a moment of distraction could cause serious injury; but robots can wield heavy and sharp knives with absolute precision,” explained Calderone.

The need for packaging without human touch is also thought about because human workers are prone to tainting foods with pathogens during the packaging process. Human workers catch colds or get sick and spread viruses and germs in the working station.

On the other hand, robots are more sanitized since operators can wash them with solvents and high-pressure water. Robots also don’t get sick or catch colds.

“Production levels in many food processing plants vary during certain seasons, making it difficult to find workers, who will work only during peaks. There is a high turn-over of employees in the meat processing plants, because of the dangers and harsh working conditions. Some plants hire on a daily basis to replace the workers who leave,” added Calderone.

Tech writer David Roberge, of Industrial Packaging, said that “production line automation allows companies to leverage ingenuity and efficiency without sacrificing craftsmanship or quality.”

“With an automated production line, you never have to worry about employees getting sick, you can rest assured that production levels will remain high, and you can feel confident knowing that the end product will be made to a consistently high standard,” he added.

Packing food via robotics technology is gaining ground because competitive companies naturally aim for a cost-effective way of doing things. Responsible companies are being careful of the operational expenses to maximize sales potential.

As robotic packaging automation can copy or even perform better than human movements, the technology can similarly deliver its task without jeopardizing the results of the process.

“This does not eliminate the need for good staff. Instead, it provides an opportunity to remove the repetitive, unskilled tasks that many humans find boring and unfulfilling yet are critical to meeting production needs,” wrote Roberge.

“Industrial robots have emerged as a valuable packaging tool for food manufacturers, as the performance and user-friendliness of the robots has increased while costs have come down. Vision-assisted robots emulate the flexibility of human hand-eye coordination, and they perform a number of inspections for quality assurance,” he added.

A Swedish dairy equipment company DeLaval unveiled its world’s first commercial robotic milking rotary at a pilot farm at Quamby Brook, Tasmania, Australia.

SAMR Industries also make robotic bottle filling machines that automatically wash the bottles, fills them with content, like sauce, vinegar, liquids, and wine. The robot also manages date printing, UV bacteria killing, plastic forming, fixed quantity filling, and sealing.

While Remtec Automation has integrated case packing and palletizing processes. The system can also handle food items on bags, cartoons, flow wrap or clamshells.

Furthermore, the Robotic Application “Multi-Task” also receives the packaged products right away from the exit of the packaging machine as a single loose product and does any kind of action on the packages like coding and date.

In the packaging process, the products are grouped according to the matrix arrangement of the wholesale package. The robot can also pick the grouped packages and put them in the wholesale package before placing them on a pallet in the required orientation.

“The Robotic Application ‘Multi-Task’ can be describe as a solution where loose products are fed into a very small close safety area, and full pallets are delivered out…This compact solution requires less floor space and fewer investments in construction. Less equipment requires fewer investments in purchasing,” the Robotic Apps said.

Additionally, the machine can deliver “high reliability, better cost efficiency, fewer failures, lower energy consumption, and lower OPEX.”

Indeed, robotic packaging gives a wide chance to maximize human resources and ensure a productivity growth.

Business leaders and researchers have considered robot packaging technology superior to human for several reasons. They have seen how routinary the packaging process is. Also, they have studied how inefficient humans are in handling products, packing cases, palletizing, picking, or placing items.

Some reasons why robots excel than humans in the packaging industry

- Accuracy

Because they are programmed, robots have immense accuracy in the packaging process. Robots can be made of slim arms and can reach objects wider. They are strong and can withstand repeated or routinary tasks. They are equipped with a precision tool so they cannot commit errors in their performances. They are more suitable in packaging and supply chain processes.

- Flexibility

Robotic packaging technology provides flexibility in the assigned task. By utilizing robotics with the guidance of an operator, the packaging of foods can be done easily. Robots can be quickly changed, reprogrammed or adjusted to the demand of time. With the simple click of a button, robots can easily be adjusted to another set of works.

- Consistency

Robot packaging machines can perform the same task repeatedly and not get tired of it. Their actions are standardized and programmed by an operator. This allows the robots to improve the task smoothly coupled with superb quality.