How Motors and Servos Control Robot Joints for Smooth Movements

Motors and servos are key to controlling robot joints and achieving smooth movements. By using servos for precise angular control, you can improve your robot's agility. Different motors, like stepper and gear motors, provide the necessary torque and efficiency based on your project's needs. Feedback systems monitor and adjust movements continuously, ensuring accuracy. Plus, motion control algorithms allow you to coordinate joint actions effectively. With all these elements working together, your robot can perform tasks naturally and reliably. There's so much more to investigate about how these technologies work together in robotics!

Overview of Motors and Servos

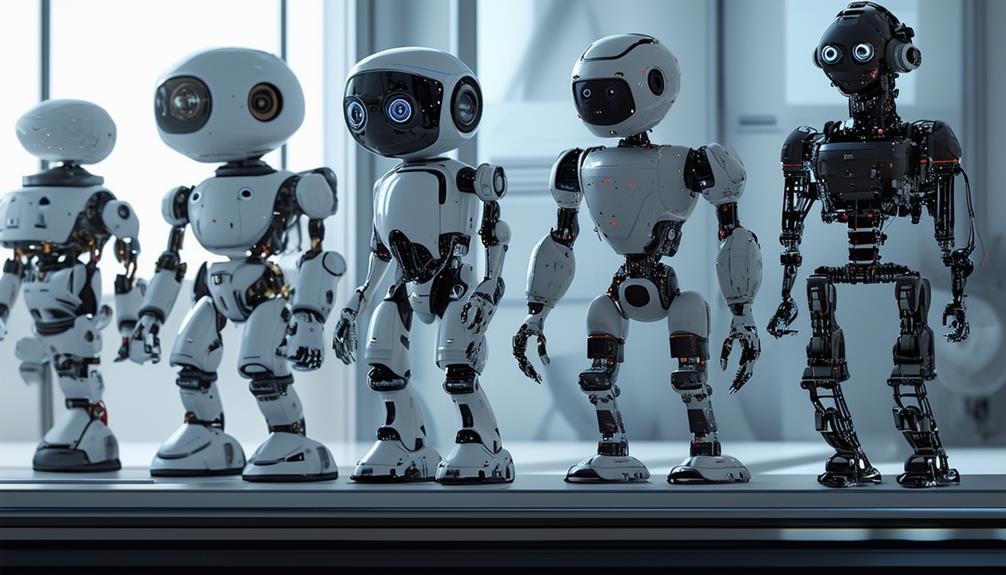

When you investigate the world of robotics, understanding motors and servos is crucial, as they play a significant role in controlling robot joints. Motors come in different types, each suited for specific applications, while servos are specialized motors designed for precise control over angular position. Incorporating these components into your projects requires a solid grasp of actuator integration, ensuring they work harmoniously within your robot's design.

Torque considerations are critical when selecting motors and servos, as they determine how much force is needed to move joints effectively. You'll want to balance this with energy efficiency, minimizing power consumption while maximizing performance. Control systems are essential in managing these components, allowing for smooth changes and accurate movements.

In your mechanical designs, consider the movement dynamics; the arrangement of motors and servos will greatly impact how your robot behaves. By carefully selecting and integrating these elements, you can create a robot that moves fluidly and efficiently, capable of handling different tasks. Understanding the interplay between motors, servos, and their applications will empower you to build more advanced robotic systems.

Types of Motors Used in Robotics

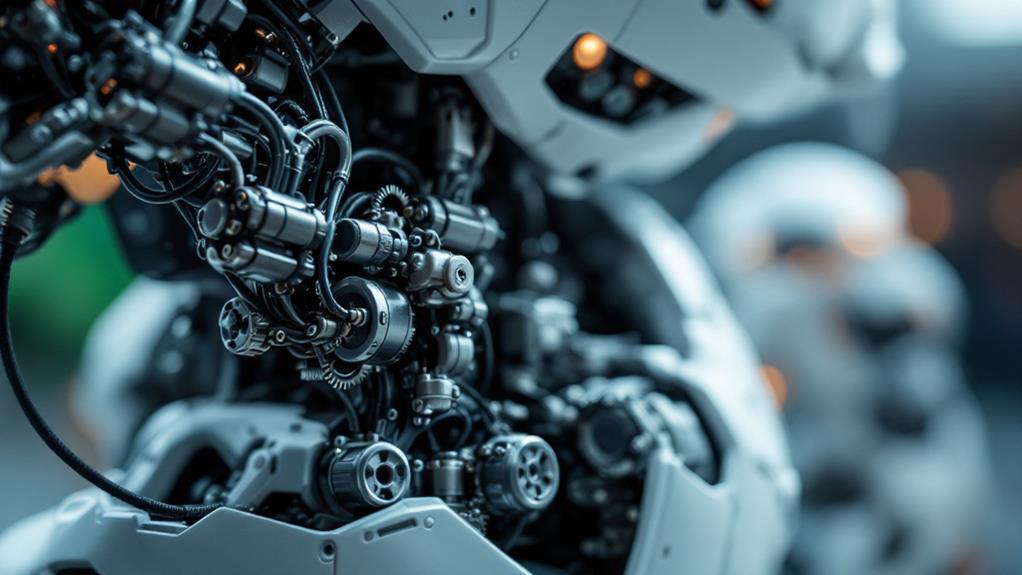

Motors are the heartbeat of robotic systems, and choosing the right type is essential for peak performance. In robotics, you'll often encounter several types of motors, each suited to different applications. Stepper motors are popular for precise positioning, thanks to their ability to move in discrete steps. Brushed motors offer simplicity and cost-effectiveness, but they wear out faster than their brushless counterparts, which provide higher efficiency and longevity.

Gear motors combine a motor with a gearing system, increasing torque ratings and providing the power needed for heavier loads. For applications requiring rapid movements, piezoelectric actuators excel by converting electrical energy into precise mechanical motion. If you're looking for linear movement, linear actuators are your go-to choice, effectively transforming rotary motion into linear displacement.

DC motors are versatile and widely used, but your motor selection should always consider the specific power requirements of your project. Understanding these different motors will help you make informed decisions and optimize your robot's performance, ensuring smooth and efficient movements throughout its operations.

Understanding Servo Mechanisms

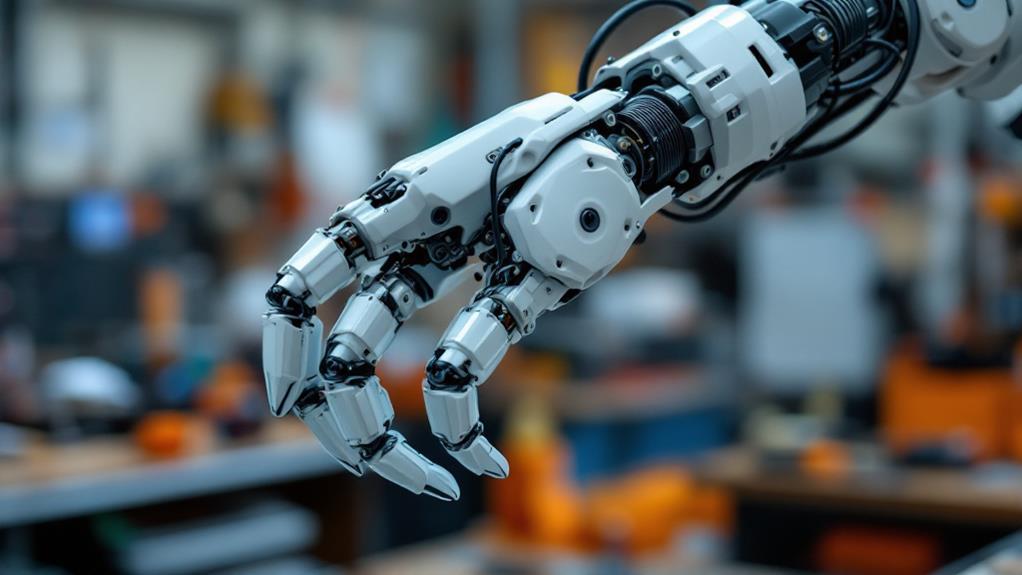

Servos are vital components in robotics, providing precise control over joint movements. To guarantee peak performance, you need to focus on servo calibration, which aligns the servo's output with the desired angles. This process minimizes errors in angular displacement, allowing for smoother motions.

Understanding the torque requirements of your application is significant. A servo must be strong enough to handle the load while maintaining motor efficiency. This means selecting a motor that can deliver the necessary torque without overexerting itself, which can lead to overheating or failure. Here, gear ratios play a substantial role, as they can amplify the torque output, enhancing your servo's capability.

Signal processing is another key factor. It helps the servo interpret commands accurately, assuring that it responds promptly to input signals. Load balancing is also significant, particularly in multi-joint robots where uneven weight distribution can affect performance.

Lastly, durability testing is vital to guarantee that your servos can withstand the rigors of operation. By focusing on these aspects, you can fine-tune your servo mechanisms for reliable and efficient robotic joint control.

How Motors Drive Robot Joints

Understanding how motors drive robot joints is key to improving performance and functionality. Motors are the heart of robotic movement, providing the necessary force to create joint flexibility. By using electric motors, you achieve precise control over the rotational dynamics of each joint, allowing for smooth and accurate movements.

Rotational dynamics come into play as you consider the torque and speed requirements for each joint. For instance, a robotic arm may need a high-torque motor to lift heavy objects, while a more delicate task, like writing, requires a motor capable of fine adjustments. You'll want to select motors that match the specific demands of your application, ensuring that each joint can move fluidly without unnecessary strain.

Moreover, the arrangement of motors impacts the entire design. By strategically placing motors near joints, you can minimize weight and improve responsiveness. This approach increases joint flexibility, enabling your robot to perform complex tasks efficiently. Understanding these principles will help you choose the right motors and configurations, ultimately leading to a more effective and capable robotic system.

Feedback Systems for Precision

Precision is essential in robotics, especially regarding controlling movements with accuracy. To achieve this, feedback systems play a key role. You'll often encounter closed loop control systems, which continuously monitor and adjust the robot's position based on real-time data. By integrating sensors, such as encoders or potentiometers, you can track the position and speed of each joint, guaranteeing that your robot responds appropriately to commands.

When you implement sensor integration, you're effectively creating a communication loop between the motors and the feedback mechanisms. If the robot deviates from its intended path, the sensors detect this error and send information back to the controller. The controller then makes necessary adjustments to the motor outputs, correcting the movement instantly. This dynamic process enables your robot to maintain precision and adapt to unexpected changes in its environment.

Without these feedback systems, you'd struggle to achieve the smooth and accurate movements robots are known for. So, as you design your robotic systems, prioritize closed loop control and sensor integration to guarantee peak performance and precision in every task.

Motion Control Algorithms

In relation to controlling robot joints, motion control algorithms are vital for guaranteeing smooth and accurate movements. These algorithms help you define how your robot should move through space, allowing for precise coordination of its motors and servos. By implementing effective motion planning strategies, you can anticipate the robot's movements, enabling it to navigate obstacles and execute tasks efficiently.

Trajectory optimization is another significant aspect of motion control algorithms. It focuses on finding the best path for your robot to follow while minimizing energy consumption and maximizing speed. By optimizing trajectories, you can improve your robot's performance, making it more responsive and agile in its actions.

You'll also want to take into account factors such as joint limits and dynamics when developing these algorithms. This guarantees that the robot operates within safe parameters while executing complex movements. By combining motion planning with trajectory optimization, you create a robust framework for controlling your robot's joints, resulting in fluid and natural motions. Ultimately, understanding and implementing these algorithms is key to achieving high-performance robotic systems that can adapt to different environments and tasks.

Benefits of Smooth Movements

When robot joints move smoothly, it significantly improves the total performance and functionality of the machine. Smooth movements boost motion fluidity, allowing robots to execute tasks with precision and grace. This not only optimizes performance but also contributes to energy efficiency, as less energy is wasted on abrupt starts and stops.

You'll notice that smoother operations lead to a better user experience. Regardless of whether you're interacting with a robotic arm or a humanoid robot, the seamless movements create a more natural feel, making tasks easier and more enjoyable. Furthermore, smooth motion plays an essential role in injury prevention. By minimizing jerky movements, you reduce the risk of accidents, especially in environments where humans and robots work side by side.

Design aesthetics also benefit from smooth movements. A robot that glides fluidly captures attention and conveys sophistication, improving its appeal. Ultimately, performance optimization is achieved when all these factors come together. By prioritizing smooth movements, you not only improve the robot's operational efficiency but also raise its overall functionality, making it a more valuable asset in any setting.

Applications in Modern Robotics

Numerous applications in modern robotics showcase the critical role of motors and servos in controlling joint movements. In automation industries, robotic arms equipped with precise motors allow for efficient assembly lines, improving productivity and reliability. These robotic applications are vital for tasks that require consistent accuracy, such as welding and painting.

In the domain of assistive technologies, motors and servos enable devices that help individuals with disabilities. For instance, powered exoskeletons use smooth movements to support mobility and rehabilitation. Likewise, surgical robots rely on these components for delicate operations, providing surgeons with improved control and precision.

Autonomous vehicles also depend on motor systems to navigate through complex environments. By utilizing advanced servos, these vehicles can execute movements necessary for steering and braking. Furthermore, drone navigation systems utilize motors to achieve stable flight patterns, enabling crucial functions like aerial photography and surveillance.

Exploration robotics, often used in environments like Mars, showcase the adaptability of motors and servos in overcoming rough terrain. These applications underline how motors and servos are indispensable in modern robotics, driving innovation across numerous sectors.

Future Trends in Robotics Movement

The advancements in motors and servos are paving the way for exciting trends in robotics movement. As you look ahead, you'll notice how these innovations are set to redefine the landscape of robotics. Here are some key trends to keep an eye on:

- Adaptive Control: Robots will increasingly adapt to their environments, ensuring smoother and more efficient movements.

- Bio-Inspired Design: Drawing inspiration from nature, robots will mimic biological movements for improved fluidity and effectiveness.

- Soft Robotics: Utilizing flexible materials, these robots will move with a gentleness that's essential for delicate tasks.

- Modular Robotics: This approach allows for easier upgrades and repairs, promoting versatility and customization in robotics.

- AI Integration: Smart algorithms will improve decision-making, allowing robots to perform complex tasks with ease.

Additionally, you'll see a focus on energy efficiency and the use of advanced sensors to enhance safety and interaction. Collaborative robots will also become more common, working alongside humans in numerous industries to increase productivity. Embracing these trends will revolutionize how robots move and interact with the world around them.