How Collaborative Robots (Cobots) Work Alongside Humans in Factories

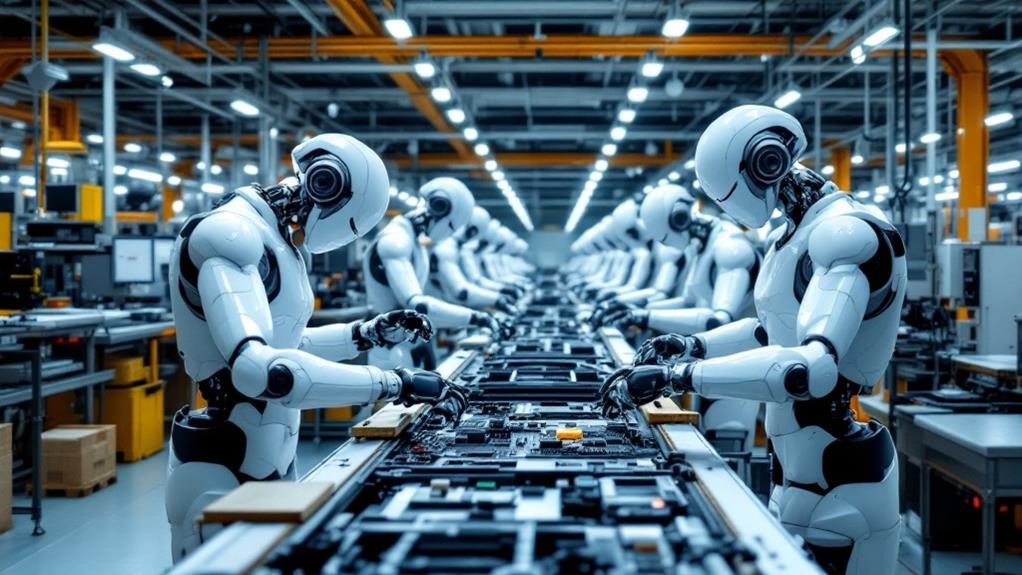

Cobots, or collaborative robots, are transforming factories by working effortlessly alongside humans to enhance productivity and safety. Equipped with advanced sensors and machine learning capabilities, these robots handle precise and repetitive tasks like assembly and packaging, allowing you to focus on more complex and creative activities. They seamlessly integrate into current workflows with minimal disruption, and they're designed ergonomically to prevent strain and improve workplace comfort. Robust training and safety protocols guarantee that cobots operate without posing hazards. Across industries from automotive to healthcare, cobots are advancing operations. Investigate further to understand their potential impact on diverse processes.

Understanding Cobots and Their Features

Understanding cobots, short for collaborative robots, is crucial as they transform modern manufacturing processes. These versatile machines work alongside humans, enhancing productivity and efficiency. By familiarizing yourself with cobot capabilities, you'll see how they're designed to perform tasks that require precision, accuracy, and repetition. Cobots can handle tasks like assembly, packaging, and inspection, allowing human workers to focus on more complex and creative endeavors. This not only optimizes your workforce but also drives innovation within the factory setting.

Emphasizing human cobot interaction, cobots are engineered to be user-friendly, making it easy for you to integrate them into existing workflows. They're programmed to learn tasks quickly and adapt to changes, which means you can deploy them without a steep learning curve. The intuitive interfaces and straightforward programming allow non-experts to operate and manage these robots efficiently. Furthermore, cobots are equipped with advanced sensors and machine learning algorithms that enable them to understand and respond to their environment, ensuring smooth collaboration with human workers.

Incorporating cobots into your manufacturing processes empowers your team, balances workloads, and ultimately increases productivity. By understanding these features, you're paving the way for a more dynamic and agile production environment.

Safety Measures and Protocols

When integrating cobots into your factory, safety is paramount. To guarantee a secure environment, you must prioritize several key elements. Initially, conduct a thorough risk assessment to identify potential hazards that cobots might introduce. This step allows you to understand the interactions between cobots and human workers, focusing on minimizing risks.

- Training Programs: Equip your team with the necessary knowledge through extensive training programs. These programs should cover safety standards and how to operate cobots effectively. Understanding emergency protocols is essential for everyone involved.

- Ergonomic Design: Cobots should be designed with ergonomics in mind to prevent strain on workers. Their integration should improve, not hinder, the workflow, making certain they're user-friendly and safe for daily operations.

- Compliance Checks and Monitoring: Regular compliance checks are critical to maintain safety standards. Incorporate workplace monitoring to guarantee ongoing adherence and to identify any new hazards that may arise. This proactive approach keeps the factory environment safe and efficient.

Integration Into Existing Workflows

How do you smoothly incorporate cobots into your existing workflows? Start by identifying specific tasks that can benefit from automation. Look for repetitive, time-consuming processes where cobots can improve efficiency. Analyzing your production line will reveal areas ripe for workflow optimization. Once you pinpoint these tasks, delegate them to cobots, allowing your human workforce to focus on more complex, value-added activities.

Next, verify that your cobots are compatible with your current systems. Many cobots are designed to be easily programmable and adaptable, which means they can seamlessly fit into existing setups without the need for extensive reconfiguration. Test the integration by running trial operations to observe how well the cobots perform alongside human workers. This process will help identify any bottlenecks or areas of improvement.

Communication is vital during this shift. Engage your team by providing training on how to interact with cobots. This not only fosters a collaborative environment but also empowers your workforce to take full advantage of these new technologies. Remember, the goal is to create a harmonious balance where both humans and cobots contribute to a more efficient and optimized workflow.

Enhancing Human Productivity

Once cobots are smoothly integrated into your workflows, the focus shifts to improving human productivity. The synergy between humans and machines is vital. By leveraging cobot ergonomics, you can create a comfortable environment that optimizes efficiency and minimizes strain. This collaboration allows for effective task delegation, with cobots handling repetitive or strenuous tasks while humans focus on areas requiring creativity and complex decision-making.

To increase productivity, consider these strategies:

- Workflow Optimization: Analyze current processes and identify where cobots can improve efficiency. This optimization guarantees that tasks are completed faster and with greater precision.

- Skill Improvement: Train your workforce to work alongside cobots effectively. By developing new skills and understanding cobots' capabilities, employees can perform tasks more efficiently and with greater confidence.

- Productivity Assessment: Use efficiency metrics to evaluate the impact of cobots on your operations. Regular assessments help identify areas for enhancement and confirm that the integration continues to boost productivity.

Applications Across Industries

Cobots, or collaborative robots, are transforming diverse industries by offering versatile applications that improve operational efficiency. In automotive assembly, cobots work alongside you to streamline production lines, handling repetitive tasks like part installation and quality checks. Their precision and endurance elevate productivity while reducing human fatigue. In healthcare, cobots assist with patient care, ensuring safe and accurate medication delivery and supporting medical staff during surgeries, thereby improving patient outcomes.

In agriculture, cobots revolutionize agricultural harvesting by performing tasks such as picking and sorting crops, allowing you to focus on strategic decisions that increase yield and sustainability. Electronics manufacturing benefits from cobots' ability to handle delicate components, enhancing precision in assembly lines and minimizing defects. Logistics optimization is another area where cobots excel, efficiently sorting packages and managing inventory in warehouses, reducing errors and speeding up delivery times.

Food packaging sees cobots ensuring hygiene and consistency, handling tasks like sorting, packing, and labeling. In construction, cobots assist with tasks like bricklaying and welding, improving safety and efficiency on-site. Finally, in metalworking processes, cobots bring precision to welding, cutting, and material handling, enhancing quality and consistency in production.

Overcoming Implementation Challenges

Implementing collaborative robots in industrial settings presents several challenges that businesses must address to fully harness their potential. Initially, cobot training is fundamental for your workforce to guarantee seamless integration. Your team needs to understand not only how to operate these robots but also how to troubleshoot and optimize their performance. This training can be time-consuming and requires a well-structured strategy.

Secondly, achieving user acceptance is vital. Employees might be skeptical of new technology, fearing job displacement or increased workload. To overcome this, communicate the benefits of cobots, such as improved safety and efficiency. Encourage a culture of collaboration where humans and robots work together, highlighting how cobots can improve job satisfaction by taking over mundane tasks.

Finally, you must navigate the trifecta of cost considerations, maintenance strategies, and scalability options:

- Evaluate initial investment and potential ROI to guarantee the financial feasibility of cobot implementation.

- Develop a maintenance plan to keep cobots operating at peak efficiency, minimizing downtime.

- Consider scalability to expand cobot use as your operations grow, ensuring they remain a valuable asset.

Future Trends in Cobot Technology

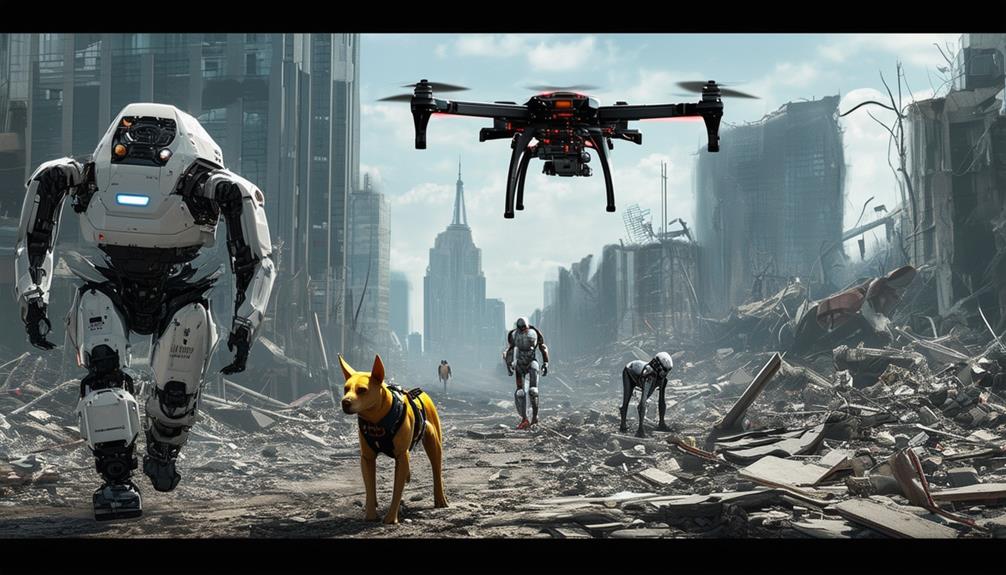

As businesses navigate the challenges of integrating collaborative robots, they also look toward the exciting advancements on the horizon. One of the most promising trends is the incorporation of machine learning and adaptive algorithms, allowing cobots to become smarter and more autonomous. These technologies enable cobots to learn from their environment, improving their efficiency and adaptability in real-time.

Advanced sensors are also playing a significant role in the evolution of cobots. These sensors improve the robots' ability to perceive their surroundings, making them safer and more effective partners in the workplace. This is complemented by user-friendly interfaces that make it easier for workers to interact and collaborate with cobots, reducing training time and increasing productivity.

Moreover, remote collaboration capabilities are becoming more prevalent, allowing for seamless integration with humans from diverse locations. This trend is particularly useful for maintenance and troubleshooting tasks, enabling predictive maintenance that minimizes downtime.

Energy efficiency and cost reduction are also key focuses, as businesses aim to implement cobots that are both eco-friendly and economical. As these technologies advance, cobots will continue to transform manufacturing environments, making them more efficient, flexible, and future-ready.

Impact on Workforce Dynamics

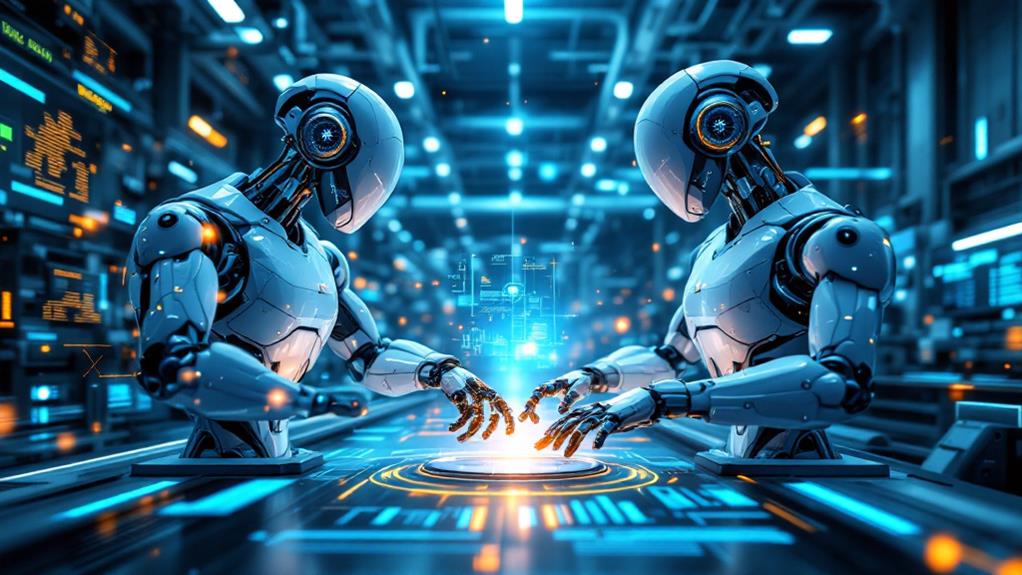

With the rise of collaborative robots, workforce dynamics are undergoing significant changes in manufacturing environments. As you observe these shifts, you'll notice that cobot acceptance plays an essential role in how smoothly these changes occur. Workers are learning to adopt cobots as partners rather than competitors. This acceptance helps alleviate fears of job displacement, making the change more harmonious.

Consider these key impacts on workforce dynamics:

- Enhanced Collaboration: Cobots are designed to work alongside you, enhancing your capabilities rather than replacing your role. They take on repetitive and dangerous tasks, allowing you to focus on more complex and fulfilling responsibilities.

- Skill Development: As cobots take over mundane tasks, there's a greater demand for skilled workers. You're encouraged to upskill and adapt to new roles that involve programming, maintenance, and oversight of these robots.

- Job Displacement Concerns: While fear of job loss exists, cobots create opportunities for new job roles. By adopting cobot acceptance, you can shift into roles that require human oversight and creativity, reducing the impact of job displacement.