For many years, the car industry has been popular for its intensive use of robotic manufacturing. It has long been one of the quickest and largest adopters of industrial robotic technology, and it still continues today. From the time when General Motors established the use of robotic systems in manufacturing cars back in 1961, the use of industrial robots has expanded over the years.

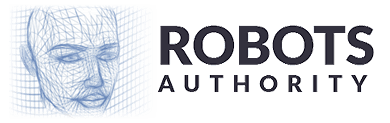

Robots give automotive companies a competitive advantage, such as improving quality and reducing warranty costs, increasing capacity and relieving bottlenecks, and as well as protecting workers from dirty, difficult, and dangerous jobs. From the 1960s, there have been a lot of enhancements done on production lines. It’s because these days, the production lines need to be more flexible, efficient, and precise.

If you are wondering how robots are used in the car industry, you’re in the right place. Today, we are giving you the different robotic applications in the automotive industry.

Robotic Vision

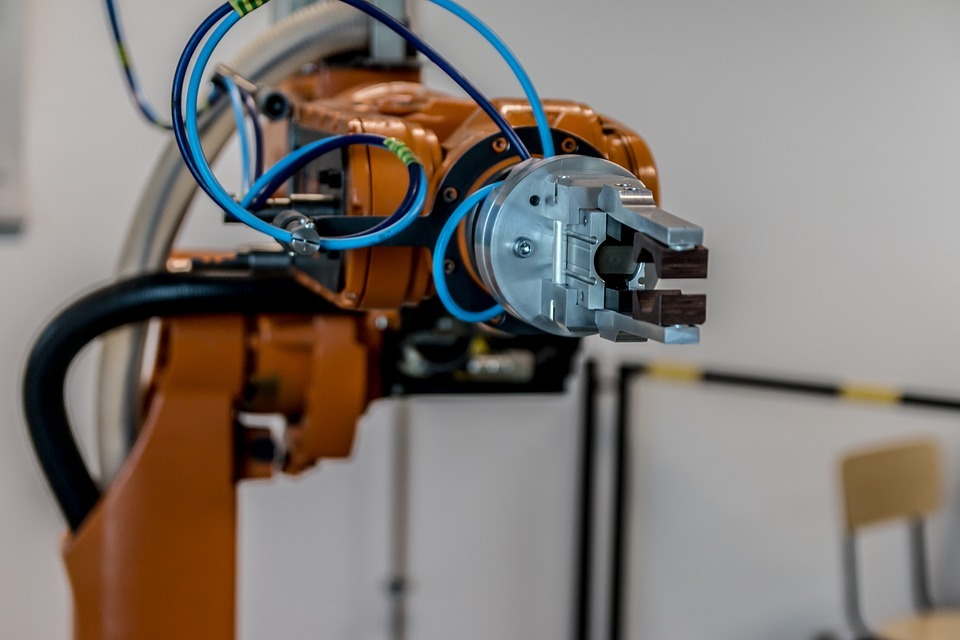

In 2013, during the production of the Ford Escape, the company introduced a robotic arm with “eyes.” There are a laser and a camera placed in a range on the robot wrist, which is able to see where the parts of the car body should be installed exactly. By giving instructions to the robot, car parts like door panels, fenders, and windshield can be installed more precisely.

With this, robots can perform proper offsetting when installing a part because they know where it should go. If there is any difference in the production, robots can adapt their installation procedure to fit the part perfectly into the car. This way, the gap between the assembled parts are reduced, which also decreases the noise caused by wind.

Spot and Arc Welding

Large industrial robots that have long arms and higher payload aptitudes are used in handling spot welding on heavy body panels. Smaller robots, on the other hand, are responsible for welding lighter parts like brackets and mounts. These robots are referred to as collaborative robots in the car industry. They work together with other large industrial robots on immense assembly lines. Both robotic welders and handlers need to collaborate in order to keep the assembly line moving. The role of the robot handlers is to place panels at the precise location so that the welding robot can do all the programmed welds.

Automated Guided Vehicles or AGVs

These are self-guided vehicles that are made to haul heavy loads and materials around a large industrial building. They are operator-free forklift-sized wheeled carriers that rely on software to navigate their movements around manufacturing plants and assembly facilities. They are often assisted by magnetic strips or lasers. By using a 3D map technology, they can carry goods over to short-to-medium distances repetitively.

In automotive companies, AGVs are used to transport cars and major components, such as front-end modules, instrument panels, and seats, through the assembly like to chassis marriage, where the chassis is synchronized with the car body. It helps in optimizing the workflow processes and as well as improve safety in the workplace.

Exoskeleton Devices

Industrial robotic arms do the majority of the automotive operations, but a lot of the assembly tasks are still done manually. Therefore, to reduce fatigue on the human hand, exoskeleton devices, which are essentially wearable robots, are used for repetitive operations in manufacturing.

One of the examples is the RoboGlove, which General Motors has developed along with NASA. It is a robotic glove that adds strength and grip to the human hand. It is worn on the back like a knapsack and driven by a mechanical delivery system to increase your grip strength. As the person grips, the robot aids him with more assistance, which greatly reduces fatigue. It has sensors, actuators, and simulated nerves, tendons, and muscles that increase manual dexterity.

Robotic Painting

Painting a car body using an industrial robotic arm is not new, but it is still an important application in car manufacturing. In the present time, it’s quite challenging to find highly qualified painters. Also, considering the size of a car, it is more convenient for a company to use robots when it comes to painting. Plus, painting is a very complex job, and it is also toxic.

One of the best things about using a painting robot is the reduction of waste material. Since they are equipped with a flowmeter, the exact same amount of paint is used on each part. In addition, robots are also useful when it comes to spraying adhesives, primers, and sealants.

Conclusion

In the past few years, robots have indeed come a long way from being intimidating and life-threatening machines to the smooth robotic technology we have today, which is adept at working hand-in-hand with humans. With the help of artificial intelligence or AI, automotive assembly lines today are more efficient, productive, and cost-effective. We hope this article helped you in learning more about how robots are used in the car industry.