Famous Robotic Inventions: The Story of the First Industrial Robot

You might find it fascinating that the primary industrial robot, Unimate, was a game-changer in the manufacturing world. Born in the early 1960s, it was designed by George Devol and Joseph Engelberger. Unimate could lift and weld with precision, dramatically improving factory efficiency and safety. Its introduction sparked discussions about the impact of robotics on employment, as it replaced humans for repetitive tasks. Despite initial skepticism, Unimate proved its worth by reducing injuries and costs, reshaping traditional manufacturing. Interested in how these machines completely transformed production lines and influenced modern automation? There's much more to uncover.

The Birth of Industrial Robotics

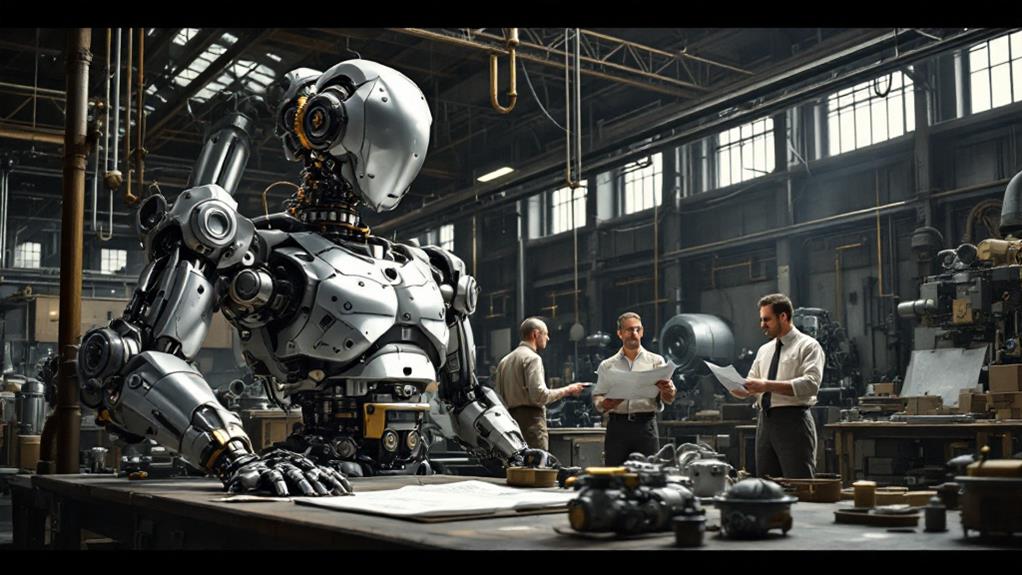

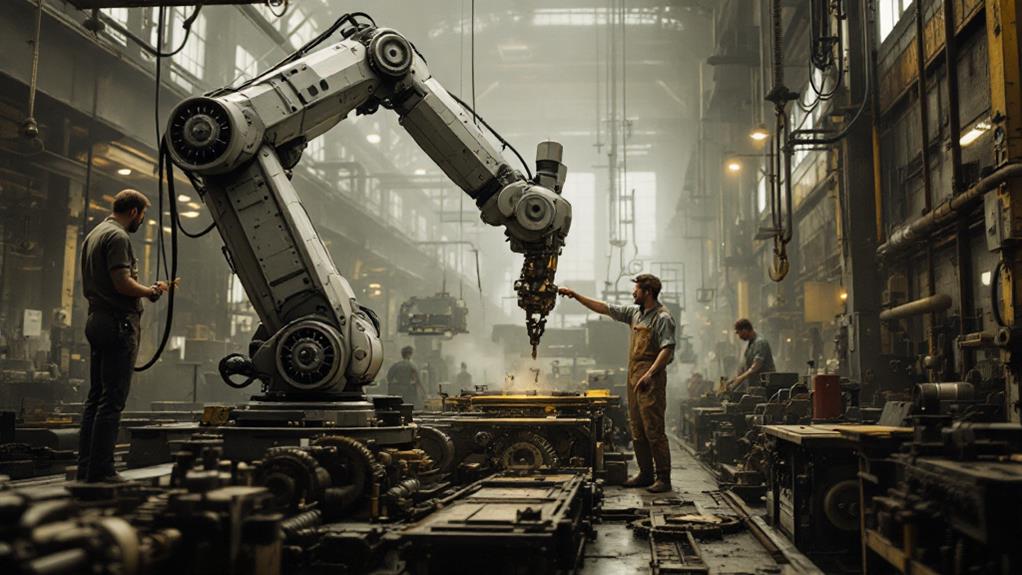

In the period of post-war innovation, the birth of industrial robotics marked a transformative phase in manufacturing. You might've noticed how industries began to evolve rapidly, driven by the automation revolution. This new epoch was characterized by the introduction of machines that could perform repetitive tasks with precision and efficiency, reshaping the landscape of factory floors. The initial industrial robot, introduced in the early 1960s, played a crucial role in accelerating this transformation. It wasn't just about increased productivity; it fundamentally changed how manufacturing processes were structured.

As you investigate this time, it's significant to understand the impact on the workforce. Industrial robotics led to a substantial shift, often referred to as labor displacement. Many workers found themselves adjusting to new roles or learning to work alongside these mechanical counterparts. While some feared the loss of jobs, others saw it as an opportunity for skill development and innovation. The automation revolution didn't just replace human labor; it redefined it. You can see how this age laid the groundwork for the sophisticated robotic systems we rely on today, demonstrating both the challenges and opportunities that come with technological advancements.

Visionaries Behind the Innovation

As the automation revolution took hold, the minds behind these groundbreaking changes deserve recognition. You might wonder who these robotic pioneers were, driving innovation breakthroughs and tackling engineering challenges. Their vision wasn't just about creating machines but reshaping industries and societies.

Reflect on these key aspects:

- Societal Implications: These pioneers didn't only focus on technical feats; they understood the broader societal implications. They foresaw how robots could redefine labor, productivity, and economic landscapes, prompting discussions on job displacement and the need for new skills.

- Ethical Factors: As technology advanced, ethical factors became paramount. Visionaries grappled with questions about human interaction with machines, privacy, and the potential for misuse. They laid the groundwork for ongoing debates about the ethical use of robotics in diverse sectors.

- Future Visionaries: While robotics began with these early innovators, they also inspired future visionaries. Today's leaders continue to push boundaries, addressing past challenges and exploring new frontiers in artificial intelligence and machine learning.

Recognizing these pioneers highlights their profound impact on shaping the world we navigate today, reminding you to reflect on both the opportunities and responsibilities that come with technological advancement.

Unimate: The First Industrial Robot

Imagine a colossal arm, moving with precision and strength on the assembly line. That's Unimate, the pioneering industrial robot, transforming manufacturing forever. You see it lifting and welding, tasks once done by human hands, now performed with unmatched accuracy. The brainchild of George Devol and Joseph Engelberger, Unimate's robot design was groundbreaking. It wasn't just a machine; it was a revolution in how industries approached production.

As you explore Unimate's history, consider the domain of automation ethics. Its introduction sparked debates about the impact of robots on jobs and the workforce. While Unimate increased efficiency and safety, it also raised questions about the displacement of human labor. How do you balance technological advancement with ethical considerations? These are questions industries still grapple with today.

Overcoming Initial Challenges

Despite the groundbreaking potential of Unimate, its creators faced significant hurdles in bringing this robotic marvel to life. Imagine being in the shoes of George Devol and Joseph Engelberger, maneuvering the uncharted waters of automation challenges and programming limitations. They needed to guarantee that Unimate wasn't just a concept but a practical solution in industrial settings. Convincing manufacturers to adopt a robot when they were accustomed to human labor was no small feat.

Here's what they had to tackle:

- Automation Challenges: Introducing a robot into an environment designed for humans meant rethinking workflows and safety protocols. Adjustments were vital to allow Unimate to operate seamlessly alongside human workers.

- Programming Limitations: At the time, programming languages were primitive. Devol and Engelberger had to innovate to create software that could handle complex tasks reliably. It required them to think beyond existing technology, pushing the boundaries of what was possible.

- Cultural Resistance: Many industries were skeptical about replacing human workers with machines. The creators had to demonstrate that Unimate wouldn't just cut costs but also improve productivity and safety.

Transforming Manufacturing Processes

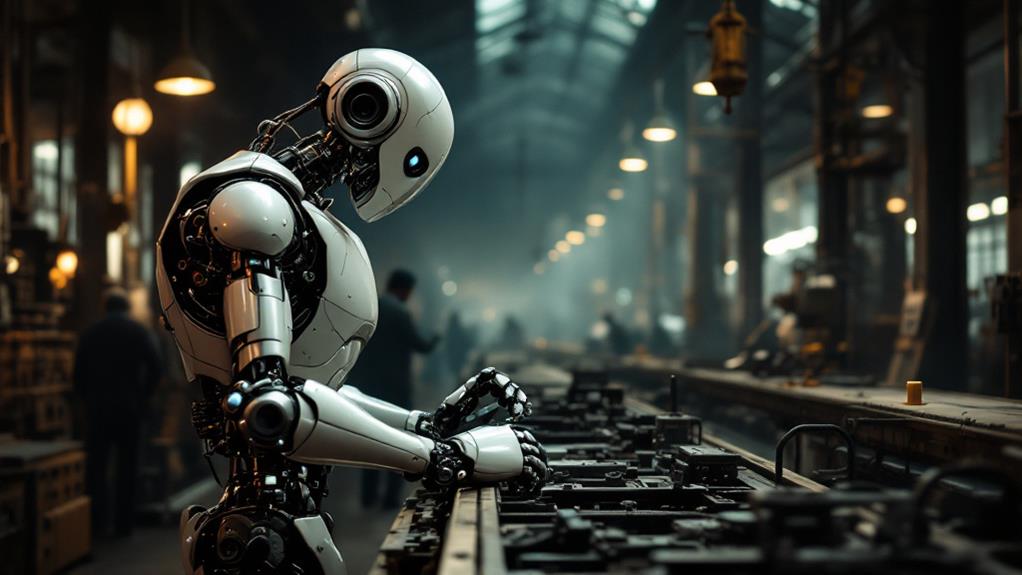

Unimate didn't just enter factories; it transformed them. You might have witnessed massive changes as automation benefits changed the manufacturing landscape. With Unimate, manufacturing efficiency soared. Tasks once requiring hours were now completed in minutes, streamlining operations and increasing productivity. Yes, there was labor displacement, but this shift also paved the way for workforce transformation. Workers moved from repetitive, hazardous tasks to roles requiring higher skills and creativity, enhancing job satisfaction.

Safety improvements became one of the most significant impacts. Unimate took on dangerous jobs, reducing workplace injuries and creating a safer environment. Cost reduction followed naturally as the robot minimized errors and waste, leading to a better bottom line. Production scalability became achievable, allowing you to meet growing demands without a hitch. Unimate could work tirelessly, ensuring consistent throughput.

Quality control advanced as well. Unimate's precision meant fewer defects and higher-quality products rolling off assembly lines. This consistency helped maintain your reputation for excellence. So, while Unimate might have displaced some jobs initially, the comprehensive transformation it brought to manufacturing processes has been invaluable, setting the stage for modern industrial innovation.

Early Industry Adoption

As manufacturing processes experienced a revolution, the early adoption of robotics in diverse industries marked a significant step forward. You saw companies embracing these machines not just for their novelty, but for their tangible automation benefits. Robotics improved productivity by performing repetitive tasks with precision, reducing human error, and allowing you to focus on more complex responsibilities. The integration of robots into the workplace may have seemed intimidating, but it was a necessary shift to stay competitive.

Workforce adaptation was vital during this period. Workers needed to adjust, learn new skills, and understand how to work alongside robots. This adaptation wasn't just about survival—it offered opportunities for personal growth and career advancement. Companies invested in retraining programs to support this change, recognizing that a well-adapted workforce was key to leveraging the full potential of automation.

Consider these points:

- Increased Efficiency: Robots streamlined operations, elevating output without compromising quality.

- Improved Safety: Automation reduced the risk of workplace injuries by taking over dangerous tasks.

- Economic Growth: Early adopters saw improved profitability, setting a trend for others to follow.

Technological Evolution and Impact

One thing's certain about technological evolution: it reshapes industries and everyday life in profound ways. When you look at the progression of industrial robots, automation advancements have transformed how production lines operate. They've driven efficiency improvement by performing repetitive tasks with precision, reducing errors, and speeding up processes. This leads to production optimization, ensuring that more gets done in less time and at a lower cost.

Incorporating robots into the industrial landscape doesn't just improve operations; it transforms the workforce. While some roles become obsolete, new opportunities arise, requiring a skill evolution. You must adapt and learn to work alongside these machines, embracing technological integration in your role. This shift opens doors for more creative and strategic positions, allowing you to focus on tasks that robots can't handle.

Safety improvements are another critical impact of robotic technology. Robots take on dangerous tasks, protecting you from hazardous environments and potential injuries. Additionally, cost reduction is a significant advantage, as robots can work tirelessly without the need for breaks or overtime pay. In summary, the technological evolution of industrial robots continues to redefine what's possible, pushing industries to new heights.

Global Influence and Expansion

Building on the transformative effects of industrial robots, their influence isn't confined to a single region. These machines are reshaping automation trends across global markets. As you observe this expansion, you'll notice how industrial robots drive a competitive advantage, increasing productivity and efficiency. But with such growth, there are significant workforce implications. Many workers must adapt or face displacement, prompting a need for retraining and skill development. This shift leads to a broader economic impact, affecting everything from job markets to national economies.

International collaboration plays an essential role in this global influence. Countries engage in technological transfer, sharing advancements and innovations to improve their own capabilities. However, such exchanges aren't without obstacles. Regulatory challenges arise as nations aim to balance innovation with safety and ethical considerations. As you navigate this landscape, consider these key points:

- Workforce Adaptation: Understand the skills required to flourish in an increasingly automated world.

- Economic Dynamics: Recognize how industrial robots alter economic structures and create new opportunities.

- Regulatory Navigation: Stay informed about regulatory challenges and how they impact technological progress.

Legacy and Future Prospects

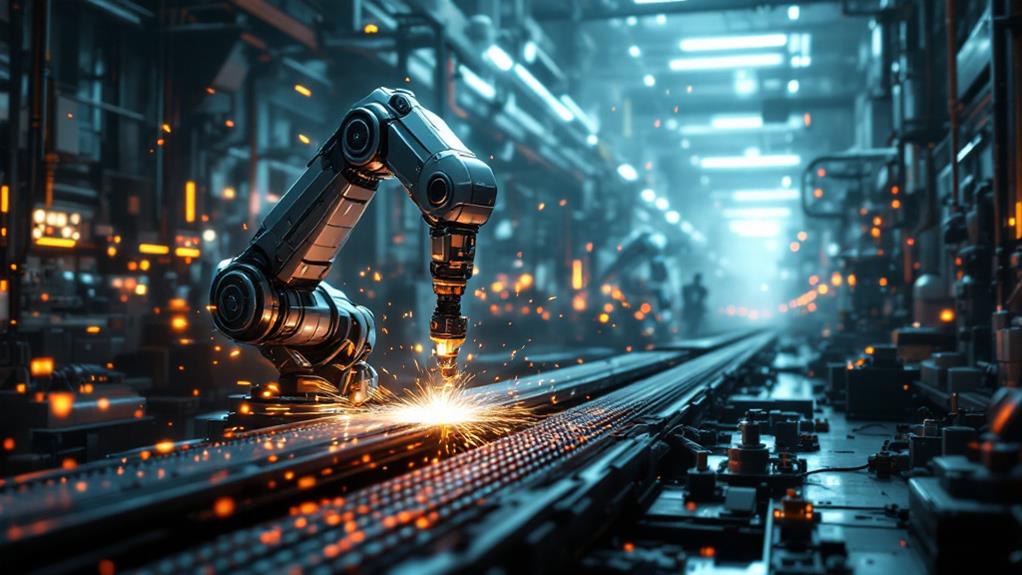

The legacy of industrial robots is undeniable, having transformed manufacturing and beyond, setting a foundation for future technological advancements. You've seen how they changed assembly lines, increasing efficiency and precision. But it's not just about what they did in the past. The real excitement lies in what comes next. As you look to the future, think about how these machines will continue shaping industries and lives.

Future automation promises to be even more profound. You'll witness robots taking on more complex tasks, from healthcare to space exploration. But with these advancements comes the need for a strong focus on robotic ethics. It's essential to guarantee that automation improves human life without compromising privacy or security. You have the power to influence how these technologies are integrated into society, maintaining a balance between innovation and ethical considerations.

As you consider the future, keep in mind that industrial robots aren't just tools; they're part of an evolving landscape that you help shape. By understanding and addressing the ethical implications, you can guarantee that the legacy of these inventions isn't just one of technological prowess but also of responsible and thoughtful progress.