Machines consist of dozens or hundreds of different parts that serve different purposes, but one of the most important parts that every machine should have is the actuator. Without the actuator, the other parts of a robot or a machine would basically be useless. So, what does an actuator do? And why is it so important for machines? Let us find out as we take a look at some details about the actuator.

Functions of an Actuator

The actuator’s main function is to move and control multiple parts of the machine so that it can function properly. So, it can be said that an actuator is the “mover” of the machine, and without it, the machine wouldn’t really work.

In order for an actuator to function, it would need a source of energy (commonly electricity) and a control signal (sends a signal to the actuator to absorb the source of energy). Both the control signal and the source energy can be an electric current, pneumatic pressure (gas or pressurized air), and hydraulic pressure (pressurized water). After getting power, the actuator would then be responsible for communicating with the machine’s control system, which would then allow the other parts of the machine to move. The control system is commonly software-based in today’s era, but there are still some machines that use mechanical and electronic systems.

Types of Actuators

There are different types of actuators that can be found in different kinds of machines. These actuators can be powered by various sources of energy, and each type would have its pros and cons as well. Here are the different types of actuators you should know about.

Pneumatic Actuator

The pneumatic actuator is able to produce power for the machine by converting pneumatic pressure, which comes from gas and pressurized air. Pneumatic actuators are most commonly used for engine controls, as this type of actuator allows the machine to start and stop quicker.

In addition to having a faster response, the pneumatic actuator is also much cheaper compared to other types of actuators. Moreover, pneumatic actuators can give the machine power with little effort to absorb its source of energy. However, the downside to pneumatic actuators is that they are hard to maintain and repair because of the many parts that are involved in the actuators’ functions.

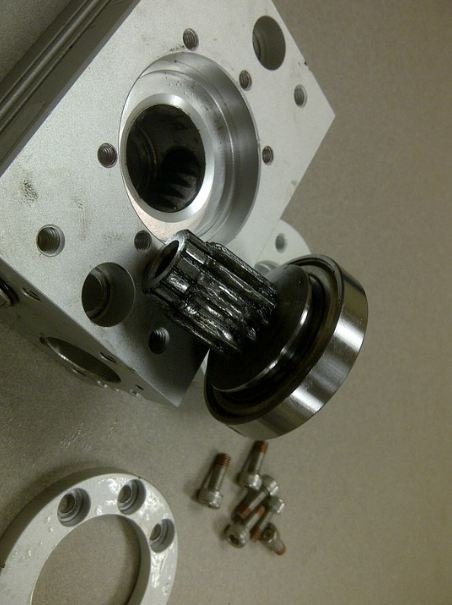

Hydraulic Actuator

The hydraulic actuator uses pressurized water as a source of energy to give power to a machine. The actuator achieves this through a cylinder or fluid motor that converts hydraulic pressure into power. The cylinder would then provide output that is in the form of oscillatory or linear motion. Because water is difficult to compress and pressurize, the hydraulic actuator can actually exert plenty of force, which makes it one of the most powerful types of actuators. But, the downside to exerting a large force is that the actuator can have limited acceleration, so it doesn’t respond as fast as the pneumatic actuator.

The cylinder of the hydraulic actuator has one or two pistons inside it, which are responsible for exerting the force within the actuator. Single-acting actuators applied fluid pressure to only one piston, while double-acting actuators apply the same pressure to two pistons.

Electric Actuator

The electric actuator gives power to the machine through an electrical source of energy. There are currently three types of electric actuators that exist, so here are brief descriptions for each of them.

- Electrohydraulic – a type of electric actuator where an electric motor serves as the main mover while also accompanied by a hydraulic accumulator that provides torque for the actuator.

- Linear Motor – the simplest electric actuator that is also versatile and highly sought-after by many manufacturers. Compared to other types of electric actuators, the linear motor is the fastest and most powerful.

- Electromechanical – a type of electric actuator that can provide power through a belt drive or a screw. Electromechanical actuators are much more accurate than pneumatic actuators, and they are also much more durable and reliable.

Thermal Actuator

The thermal actuator is activated when thermal energy or heat is applied to it. Thermal actuators are relatively small compared to other types of actuators, and because they are small, they are also lightweight and economical.

Soft Actuator

Soft actuators, as their name suggests, are actuators that are made of soft materials that allow them to change shapes in order to follow the motion or the change in the shape of the machine that they are moving. Because of how flexible soft actuators are, they are often used in machines that require a lot of movement, which include robots.

Actuators are arguably the most important part that machines should have, as they wouldn’t even be called “machines” without actuators since they cannot move or function. Maintenance of the actuator is also essential, as keeping it in pristine and working condition is crucial in the overall mechanism of the machines.