The Role of Microcontrollers in Robotic Systems: How They Manage Multiple Parts

You'll find that microcontrollers act as the central brain of robotic systems, making essential decisions and managing interactions between diverse components. They handle input/output operations, adjust motor speeds through precise signal generation, and integrate sensor data for accurate environmental analysis. By processing complex algorithms, they guarantee that every part works harmoniously and efficiently. They also play a key role in optimizing power consumption and enhancing system scalability, supporting upgrades without sacrificing performance. Through effective real-time task coordination, microcontrollers prevent mechanical errors and maintain smooth operations. Uncover how these tiny controllers revolutionize robotics with such impactful capabilities.

Understanding Microcontrollers in Robotics

When diving into the domain of robotics, understanding microcontrollers is vital as they're the brains behind the operation. You can't create an efficient robotic system without comprehending how microcontroller architecture functions. This architecture determines how microcontrollers process data, control tasks, and communicate with other components. At the heart of it, you'll find that microcontrollers handle everything from basic input/output operations to complex decision-making processes. They do this by using a set of instructions defined by their architecture.

To effectively program these microcontrollers, you'll need to familiarize yourself with multiple programming languages. Languages like C, C++, and Python are commonly used, each offering unique benefits. C and C++ are often preferred for their efficiency and control over hardware, while Python is praised for its simplicity and ease of use when developing and testing algorithms. By mastering these languages, you're able to write code that directs the microcontroller to perform specific tasks, making your robot function as intended.

In robotics, understanding the synergy between microcontroller architecture and programming languages is fundamental. It empowers you to design robots that can respond dynamically to their environments, ultimately enhancing their functionality and efficiency.

Key Components of Microcontrollers

At the core of microcontrollers, you'll find several key components that make them indispensable in robotic systems. Initially, consider the diverse memory types, like flash, RAM, and EEPROM, which store and process data efficiently. These memory types guarantee that robots execute tasks accurately and swiftly. Power management is another significant component, as it optimizes energy use, extending the lifespan of both the microcontroller and the robot.

Communication protocols are also essential, facilitating seamless interaction between the microcontroller and other parts of the robotic system. Regardless of it being I2C, SPI, or UART, these protocols guarantee data is transmitted and received reliably. System integration hinges on compatibility with different programming languages, allowing you to tailor the microcontroller's functionality to specific applications.

Reliability factors are non-negotiable; microcontrollers must withstand multiple operational conditions. Robust debugging techniques are crucial for identifying and resolving issues promptly, enhancing general system reliability. Application examples of microcontrollers in robotics include sensor management, decision-making processes, and autonomous navigation.

Motor Control and Management

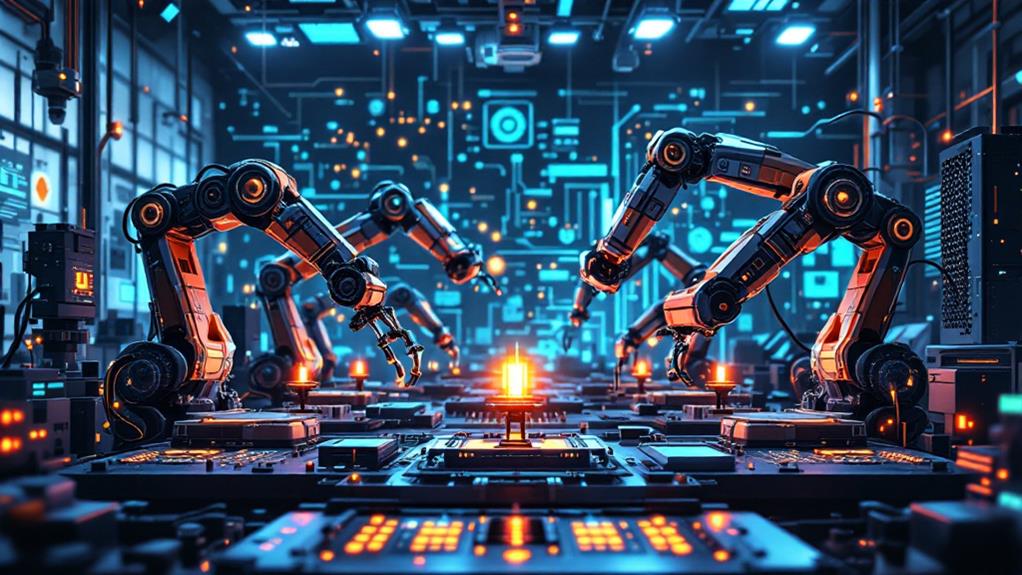

Understanding the intricacies of microcontrollers leads us naturally to the fundamental role they play in motor control and management within robotic systems. You'll find that microcontrollers are critical for actuator interfacing, allowing precise control over the motors that drive robot movement. They generate PWM signals, which determine the speed and direction of motors. By adjusting these signals, you can directly influence how a robotic system maneuvers.

To guarantee peak performance, microcontrollers use control algorithms that process data from diverse sources. These algorithms work in tandem with feedback loops, continuously adjusting motor output based on real-time information to maintain accuracy and efficiency. This dynamic adjustment is essential for applications requiring high precision, such as robotic arms or autonomous vehicles.

Another key aspect is thermal management. Microcontrollers monitor temperature levels to prevent overheating, which can damage motors and reduce lifespan. They also focus on power optimization, minimizing energy consumption while maintaining performance.

Signal conditioning and noise reduction are also integral. By filtering out unwanted noise, microcontrollers guarantee that only clean, accurate signals are used for motor control. This improves reliability and reduces the risk of errors, making your robotic system more robust and dependable.

Sensor Integration Techniques

In robotic systems, integrating sensors effectively is fundamental for improving functionality and accuracy. You need to evaluate sensor types and how they interact within sensor networks to gather extensive data. Sensor fusion plays a significant role here, combining inputs from multiple sensors to provide a more precise picture of the environment. This isn't just about collecting data; it's about improving environmental sensing by blending inputs, thereby reducing uncertainty.

To achieve this, you'll focus on signal conditioning, which guarantees the raw signals from sensors are clean and usable. Proper sensor calibration is also important, as it assures that each sensor provides accurate readings, critical when integrating diverse sensor types. Without calibration, the data acquisition process might yield inconsistent results, undermining the system's reliability.

Feedback mechanisms are another key aspect, as they allow the robotic system to respond to its environment dynamically. By integrating these mechanisms, you guarantee that the system can adapt based on real-time sensor information. Essentially, your goal is to create a seamless integration where the sensors work collectively, providing robust data to improve the overall performance and precision of your robotic systems.

Data Processing Capabilities

Efficient data processing capabilities frequently determine the success of a robotic system. When you're dealing with robotics, microcontrollers act as the brain, managing how the robot interprets and responds to its environment. Initially, you need to understand that data acquisition is vital. Sensors gather vast amounts of information, and microcontrollers must quickly and accurately process this data to guarantee the system functions properly. Without robust data acquisition, your robotic system might falter, unable to react to changes or perform tasks effectively.

Once data is collected, signal processing becomes the next essential step. Here, microcontrollers filter and refine the raw data, converting it into a usable form. They handle everything from noise reduction to feature extraction, confirming your robot interprets its environment accurately. This process allows the robotic system to identify patterns, detect anomalies, and make informed decisions.

Real-Time Task Coordination

In relation to real-time task coordination, microcontrollers play an important role in guaranteeing your robotic system works seamlessly and efficiently. They're the brains behind the operation, juggling multiple tasks and making certain everything runs smoothly. You'll find that task prioritization methods are significant here. Microcontrollers assess which tasks are most important at any given moment, allowing your robot to focus on necessary functions, like avoiding obstacles or executing precise movements. By prioritizing tasks effectively, your robot can respond to changes in the environment without missing a beat.

Synchronization strategies are similarly important in real-time coordination. You'll want to guarantee that all parts of your robotic system communicate and work together harmoniously. Microcontrollers manage synchronization by aligning the timing of different components, making sure they don't conflict or cause delays. This coordination helps maintain overall system stability and performance, preventing issues like data bottlenecks or mechanical errors.

Enhancing Efficiency in Robotics

How can you make your robotic systems more effective? Start by focusing on energy optimization. Microcontrollers play a critical role in managing how power is distributed among different components. By prioritizing energy-efficient algorithms and low-power modes, you can extend battery life and reduce total energy consumption. This not only cuts costs but also enhances the reliability of your robots, enabling them to perform longer tasks without interruptions.

Another key factor is system scalability. As your robotic systems grow, you need microcontrollers that can handle increased loads without compromising performance. Choose microcontrollers that support modular upgrades, allowing you to easily add or replace components. This flexibility guarantees that your system can adapt to new technologies and increased demands over time.

Moreover, consider implementing predictive maintenance. Microcontrollers can monitor system health and predict when components might fail, allowing you to perform maintenance before issues arise. This proactive approach minimizes downtime and optimizes efficiency.

Future Trends in Microcontroller Technology

Imagine microcontrollers transforming with cutting-edge advancements that redefine what's possible in robotic systems. These tiny powerhouses are on the brink of a revolution, integrating quantum computing for unprecedented processing speeds. You can expect microcontrollers to handle complex calculations in real-time, bringing sophisticated AI integration into even the smallest robots. Edge processing will also become more prevalent, allowing devices to make decisions locally without relying on cloud connectivity, enhancing both speed and privacy.

You'll see a move towards energy harvesting, where microcontrollers draw power from their environment, reducing the need for frequent battery replacements. Wireless communication will improve, making it easier for robots to interact seamlessly with other devices and networks. Open source platforms will foster innovation, letting you customize and optimize microcontroller functions to suit specific robotic needs.

Here's what to look forward to:

- Quantum computing: Revealing new levels of processing power.

- Edge processing: Amplifying efficiency by handling data locally.

- AI integration: Enabling smarter, more autonomous robots.

- Energy harvesting: Extending operational life without recharging.

- Advanced security: Protecting data with robust encryption.

With these trends, microcontrollers will not only manage robotics but also drive them to new heights.