The Role of Gears and Motors in Modern Robots

In modern robots, gears and motors are essential components that determine efficiency, precision, and adaptability. You'll find gears modulating speed and torque, tailoring a robot's movement to specific tasks. The choice of materials affects durability—with metals offering strength and plastics providing quieter operation. Different gear types like spur and helical serve unique functions. Motors dictate a robot's performance and energy usage. From stepper motors to brushless varieties, they offer diverse application possibilities. Seamless integration between gears and motors improves output and flexibility. Understanding their interplay is key to revealing the full potential of robotic systems. Investigate further to see how these elements revolutionize robotics.

Understanding Gears in Robotics

In the context of understanding gears in robotics, the devil is in the details. You need to focus on gear ratios, which determine the speed and torque of your robot's movement. Selecting the right gear materials is vital; they impact durability and efficiency. Metals might offer strength, but plastics can reduce gear noise. When you're designing gear trains, consider how they influence gear efficiency. A well-planned arrangement can minimize energy loss and enhance output.

To guarantee longevity, pay attention to gear wear. This involves selecting materials that can withstand the operational stresses of your specific gear applications. Gear alignment is another key factor; misalignment can cause premature wear and increase noise. Speaking of gear noise, it's something you'll want to reduce, especially in applications where silence is golden.

Gear selection goes hand-in-hand with gear design. You'll need to determine the specific requirements of your robotic system to choose the best gears for the job. Whether it's for precise movements or powerful torque, your choices will affect performance. Understanding these elements will allow you to optimize your robot's capabilities and guarantee reliable operation in the field.

Types of Gears Used

In relation to choosing gears for modern robots, you'll encounter a variety of types, each with its own unique advantages. Spur gears, known for their simplicity and ease of gear manufacturing, are ideal for applications needing straightforward gear integration. They offer high gear efficiency but can be noisy. On the other hand, helical gears provide quieter operation due to their angled teeth, making them suitable for more complex gear applications. Bevel gears, with their ability to change the direction of shaft rotation, are vital in gear design where angular motion is required.

When considering gear materials, you'll find that metals like steel offer durability, while plastics can reduce weight and cost. The choice of materials directly affects gear maintenance, as metal gears might need lubrication, while plastic gears require less upkeep but may wear out faster under heavy loads. Gear ratios play a significant role in determining speed and torque; worm gears excel in high-ratio applications, providing compact solutions for space-constrained designs.

Motors in Robotic Systems

As you investigate the world of robotic design, understanding the interplay between gears and motors becomes fundamental. Motors are the driving force behind a robot's movement, and getting the motor selection right can make or break your design. Consider the motor types available and how each aligns with your specific motor applications. Regardless of whether you're building an agile drone or a robust industrial arm, motor integration with gears affects general motor performance.

Choosing the right motor isn't just about power; it's about efficiency and motor reliability too. Advances in motor technology have led to more compact, powerful, and energy-efficient options. These motor advancements enable robots to perform complex tasks with precision and durability. You'll want to confirm your motors are reliable, reducing the risk of downtime in critical operations.

Don't forget about motor maintenance, which is significant for long-term performance. Regular checks and servicing can prevent unexpected failures and extend the lifespan of your motors. By prioritizing proper motor integration and maintenance, you guarantee that your robotic system operates smoothly and effectively. Remember, the right motor choice is crucial for achieving your design goals in robotic systems.

Types of Robotics Motors

When immersing into the types of robotics motors, you'll find a diverse selection suited to different applications, each with its own strengths and limitations. Stepper motors stand out for their precise control over movement, making them ideal for applications requiring exact positioning. Brushed motors, while simpler and cost-effective, wear out faster due to brush erosion. In contrast, brushless motors offer greater efficiency and longevity, making them a popular choice in modern robotics.

Servo motors combine the advantages of both stepper and brushless motors, providing precise control and high efficiency, perfect for articulated robotic arms. Linear actuators convert rotational motion into linear movement, crucial for tasks requiring straight-line motion. Piezoelectric motors excel in micro-movements, utilizing the piezoelectric effect for ultra-fine precision, suitable for delicate applications.

High torque motors deliver the power needed for heavy-duty tasks, while micro motors are perfect for compact, intricate environments. Gearhead motors incorporate gears to improve torque without increasing the motor's size, and planetary motors use planetary gear systems to provide high torque in a compact form factor. Each type offers unique benefits, allowing you to choose the right motor for specific robotic needs.

Gear-Motor Synergy

Over time, the synergy between gears and motors has transformed the capabilities of modern robots. When you look at a robot, you might not immediately consider the intricate dance between its gears and motors, but this partnership is essential. By integrating motors with gears, you achieve a harmonious blend that improves the robot's performance. Gear reduction plays a significant role in this synergy, allowing motors to deliver more efficient power output. With gear reduction, you can adjust the motor's speed and torque to suit specific tasks, making your robot more adaptable.

Motor integration is another key aspect. It's not just about attaching a motor to a set of gears; it's about ensuring they work seamlessly together. This integration means you can create robots that are precise and flexible, capable of performing complex tasks with ease. By optimizing how these components interact, you're able to build robots that are not only powerful but also efficient. So, when you're designing or working with robots, pay close attention to how gears and motors are integrated. This synergy is what enables your robot to function effectively in different applications.

Enhancing Torque and Speed

Enhancing a robot's torque-speed performance is vital for tackling a range of tasks efficiently. To achieve this, you need to focus on torque amplification and speed optimization. By amplifying torque, you can guarantee that your robot has the necessary power to perform demanding tasks, such as lifting heavy objects or moving against resistance. This amplification can be achieved using gear systems that increase the force output relative to the motor's input.

On the other hand, speed optimization allows your robot to perform tasks quickly, which is significant for applications that require rapid responses or high throughputs, such as assembly lines or high-speed sorting. To optimize speed, you should select motors and gear ratios that enhance the robot's velocity without sacrificing too much torque.

Balancing torque amplification and speed optimization is key to enhancing your robot's complete performance. By carefully selecting and configuring the right motors and gears, you can tailor your robot's capabilities to meet specific operational requirements. Consider the task demands and environmental conditions your robot will face, and adjust the gear-motor setup accordingly. This thoughtful approach guarantees that your robot operates efficiently, maximizing its potential across a range of applications.

Precision and Control Mechanisms

In modern robotics, precision and control mechanisms play an imperative role in ensuring accurate and reliable performance. When you're designing robots, you need to focus on achieving the right balance of precision and control. Servo control systems are essential for this. They allow you to fine-tune the movement of robotic joints, ensuring each motion is executed with exactitude. By incorporating feedback loops, you can constantly monitor and adjust the robot's actions, maintaining high levels of accuracy.

Consider these key aspects of precision and control mechanisms:

- Servo Control: With servo control, you gain the ability to precisely manage motor positions, which is critical for tasks requiring high accuracy, such as surgical robots.

- Feedback Loops: These loops continuously provide data on the system's output, allowing for real-time adjustments and corrections. This results in improved stability and precision.

- Dynamic Adjustments: The integration of servo control and feedback loops enables your robot to make quick adjustments to external changes, ensuring ideal performance even in unpredictable environments.

Energy Efficiency in Robots

Regarding energy efficiency in robots, you're looking at a crucial aspect that can greatly influence both operational costs and environmental sustainability. Effective power management guarantees that your robot uses energy wisely, minimizing unnecessary energy consumption. With the increasing interest in sustainable robotics, integrating renewable energy sources like solar or wind can greatly improve energy efficiency. Furthermore, energy harvesting technologies can capture and reuse energy that would otherwise be wasted, contributing to energy recovery.

Battery efficiency is another vital factor. By optimizing how your robot charges and discharges its batteries, you can extend their lifespan and reduce the frequency of recharging. This not only saves energy but also reduces waste and lowers costs. Efficiency optimization involves fine-tuning every component of your robot to confirm it performs its tasks using the least amount of energy possible.

Adopting these strategies improves both the environmental footprint and the operational efficiency of your robotic systems. By focusing on energy recovery and minimizing energy consumption, you make strides toward sustainable robotics. Implementing these energy-efficient practices can lead to more sustainable and cost-effective robotic solutions in the long run.

Innovations in Gear and Motor Design

Regarding advancements in gear and motor design, today's progress is transforming how robots operate and perform tasks. You're witnessing a shift towards more efficient and versatile robots thanks to cutting-edge developments. These advancements focus on several key areas:

- Smart Gears and Hybrid Motors: Integrating smart gears with hybrid motors improves performance. These smart gears use sensor feedback for real-time adjustments, ensuring precise movement and reducing wear.

- Advanced Actuation and Motor Integration: By combining advanced actuation with seamless motor integration, robots achieve smoother and more responsive motions. This integration allows for compact mechanisms that fit into smaller, more challenging spaces, making robots adaptable to diverse environments.

- Modular Designs and Lightweight Structures: Modular designs are becoming the norm, allowing robots to be easily customized for different tasks. These designs incorporate lightweight structures, which reduce energy consumption and improve mobility.

Using cutting-edge gear materials boosts durability and efficiency, while adaptive systems allow robots to modify their actions based on external conditions. As you investigate these advancements, you'll find that they're not just improving robotic capabilities but also paving the way for new applications. Welcome these changes and consider how they can be applied to your projects to push the boundaries of what's possible in robotics.

Future Trends in Robotics Actuation

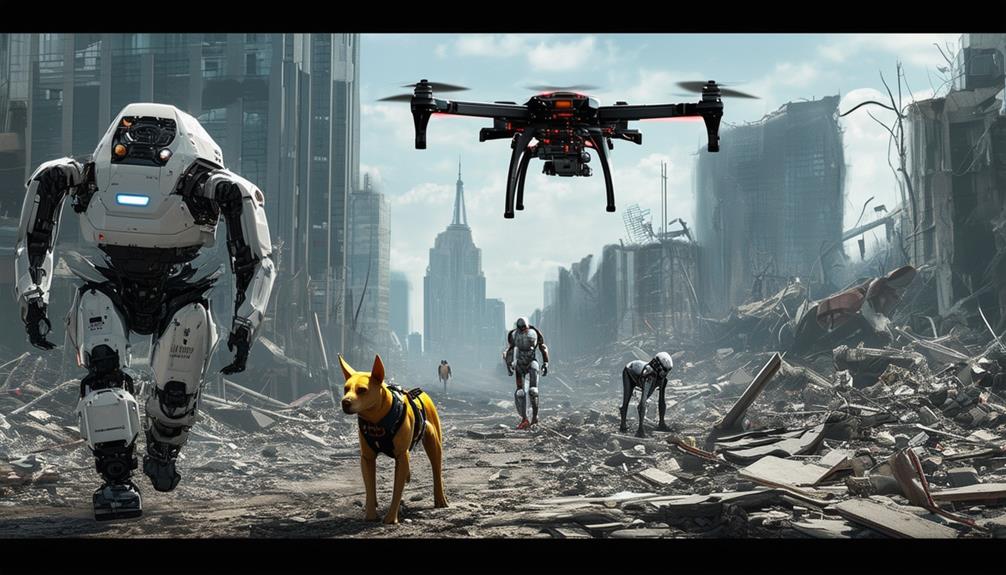

As we look toward the future of robotics actuation, emerging trends promise to revolutionize how robots move and interact with their environments. Soft robotics is at the forefront, offering flexibility and adaptability. Inspired by nature, bio-inspired actuation mimics the efficiency of biological systems, enabling robots to perform complex tasks with grace and precision. You can expect modular robotics to improve versatility, allowing for easy reconfiguration to suit different applications.

Autonomous navigation will enhance as machine learning integration and sensor fusion provide robots with the ability to understand and react to their surroundings more intelligently. Robotic exoskeletons will become more prevalent, giving humans augmented strength and endurance. Adaptive control systems will allow robots to adjust their actions on-the-fly, making them more efficient and effective in dynamic environments.

In multi-robot systems, expect collaborative functions where robots communicate and work together seamlessly. Smart materials, which change properties in response to external stimuli, will lead to more responsive and efficient robotic systems. With these advancements, you'll see robots becoming increasingly capable, opening up new possibilities across industries and daily life. The future of robotics actuation is bright, filled with potential and transformative innovations.