The History of Robotic Arms: From Industrial Automation to Space Exploration

You're about to uncover how robotic arms have transformed tasks, from repetitive industrial jobs to intricate space operations. Emerging in the mid-20th century, these machines began by mimicking simple human tasks, evolving markedly with the introduction of Unimate, the initial industrial robot. Robotic arms improved manufacturing precision and safety, paving the way for collaborative robots in medicine and surgery. They've become essential in space missions, aiding construction, maintenance, and sample collection. Today's advancements include integrating AI and real-time feedback, propelling these tools into future innovations. Set forth to investigate the fascinating expedition and implications of robotic arms.

Early Developments in Robotics

The origins of robotics trace back to the mid-20th century when inventors and engineers began experimenting with machines that could mimic simple human tasks. During this period, you would have witnessed the birth of devices designed to automate repetitive actions. These early robotic units laid the groundwork for what we now know as robotic arms. By applying fundamental robotic principles, pioneers crafted machines that could perform tasks like lifting and moving objects, albeit in a very basic form.

As you explore these early developments, it's vital to reflect on the ethical considerations that arose even then. You might wonder how society reacted to machines potentially replacing human jobs. Concerns about job displacement and the implications of autonomous machines were topics of debate, prompting discussions that still resonate today. Engineers had to balance innovation with responsibility, ensuring that their creations served humanity positively.

The Rise of Industrial Automation

Imagine a world where machines seamlessly handle monotonous tasks, freeing humans to focus on creativity and innovation. This vision is becoming reality with the rise of industrial automation. Collaborative robots, or cobots, work alongside humans in smart manufacturing settings, improving productivity and efficiency. These machines are designed to safely interact with people, adhering to strict safety standards while optimizing operations.

As automation becomes more prevalent, there's a dual narrative to reflect on: the benefits it brings and the challenges it poses. On one hand, automation benefits industries, leading to significant productivity improvement and economic impact. Companies can produce goods faster and with higher precision, reducing costs and increasing competitiveness in the global market.

On the other hand, labor displacement is a concern. As machines take over repetitive tasks, workers must adapt by acquiring new skills. Workforce adaptation is essential to guarantee that humans and machines can coexist in this evolving landscape. Training programs and educational initiatives help bridge the gap, preparing workers for roles that require more complex problem-solving and creativity. In this transformative period, embracing change is fundamental to harness the full potential of industrial automation.

The Unimate: A Pioneering Force

Innovation in robotics took a giant leap forward with the introduction of the Unimate. As the initial industrial robot, it transformed manufacturing and set the stage for future advancements. Picture yourself in the late 1950s, witnessing this groundbreaking machine in action. Unimate's features included a programmable arm capable of executing repetitive tasks with precision and strength that humans couldn't match. It handled tasks like welding and material handling, which were both hazardous and monotonous for human workers.

Now, consider the Unimate impact on the industry. It redefined production lines by markedly increasing efficiency and safety. By automating dangerous tasks, it reduced workplace injuries and allowed companies to allocate human workers to more complex, less physically demanding roles. You'd see factories becoming more productive and competitive, thanks to this robotic pioneer.

Moreover, the Unimate didn't just change manufacturing; it inspired a wave of innovation. Its success proved that robots could be reliable and cost-effective, encouraging further research and development in robotics. As a result, you witnessed the birth of a new age in automation, paving the way for increasingly sophisticated robotic arms that would continue to evolve and inspire.

Evolution of Robotic Arms

How far have robotic arms come since the days of the Unimate? From the initial industrial robot that transformed manufacturing lines, robotic arms have evolved into sophisticated machines capable of much more. Today, they're not just about repetitive tasks; they're integral parts of many industries, including healthcare and space exploration.

One of the key advancements in robotic arms is the integration of haptic feedback. This technology allows you to feel what the robot feels, providing a level of precision and control previously unattainable. Haptic feedback is essential in fields like surgery, where a surgeon can remotely operate with the sensation of touch, enhancing accuracy and safety.

Collaborative robots, or cobots, represent another significant leap in the evolution of robotic arms. Unlike traditional robots that work in isolation, cobots are designed to work alongside humans, sharing tasks and enhancing productivity. They're equipped with sensors and safety features that allow them to operate safely in close proximity to people. This collaboration expands the potential applications of robotic arms, making them more versatile and accessible.

In essence, robotic arms have transformed from solitary machines into interactive partners, driving innovation across multiple domains.

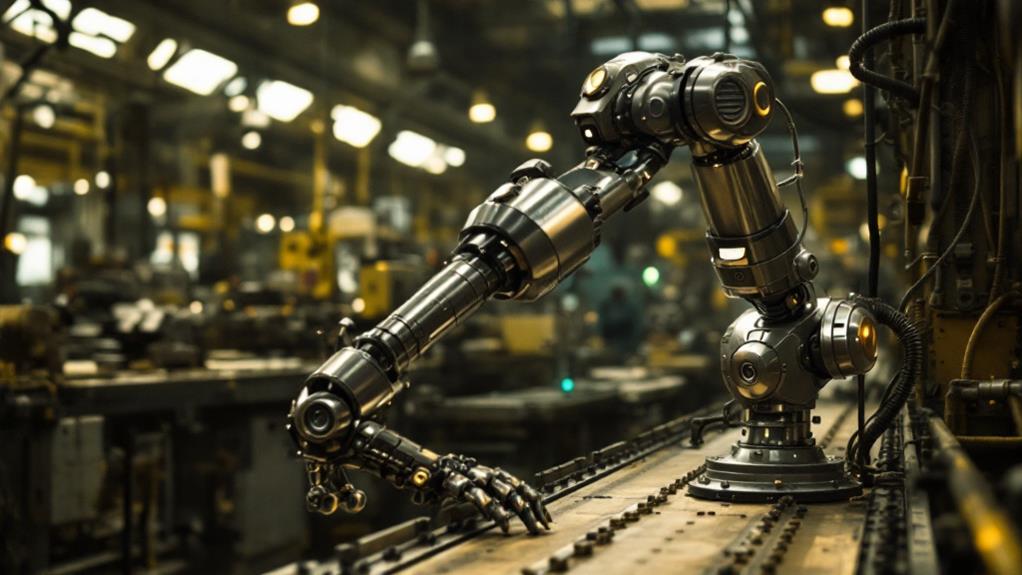

Integration in Automotive Industry

Robotic arms have become essential in the automotive industry, transforming how vehicles are manufactured. These advanced machines streamline the production line, enhancing speed and efficiency. By incorporating robotic assembly, you're able to produce high-quality vehicles at a much faster rate than traditional methods. This technological leap means you can meet growing consumer demands while reducing costs.

In today's factories, collaborative robots, or "cobots," work alongside human employees, making the manufacturing process safer and more efficient. These cobots are designed to be user-friendly, guaranteeing you can easily integrate them into existing workflows. They adapt to different tasks, from welding and painting to assembling intricate components.

You'll find some significant benefits of using robotic arms in automotive manufacturing:

- Increased Precision: Robotic assembly guarantees each vehicle is built to exact specifications, minimizing errors and waste.

- Enhanced Flexibility: Cobots can switch between tasks quickly, allowing you to adapt to changing production needs.

- Improved Safety: With collaborative robots handling dangerous tasks, workplace accidents are reduced.

Advances in Precision and Dexterity

With considerable advancements in precision and dexterity, robotic arms are transforming industries beyond just automotive manufacturing. You've probably noticed how these mechanical marvels can now perform tasks requiring exceptional finesse. This is all thanks to innovations in adaptive control systems that allow robotic arms to adjust their movements in real-time. They're not just rigid machines anymore; they adapt and respond to their environment, ensuring tasks are completed with utmost accuracy.

Imagine a scenario where human robot collaboration is crucial. In such environments, robotic arms equipped with precision sensors work seamlessly alongside human operators. These machines are capable of picking up even the smallest objects or performing delicate tasks without error. You might find them in electronics assembly lines, handling tiny components with ease.

The key is adaptive control, which enables these robotic arms to learn from their interactions and improve over time. This means increased productivity and reduced errors, as the robots fine-tune their movements to better suit specific tasks. As you see these advancements unfold, it's clear that robotic arms are reshaping how industries operate, pushing the boundaries of what's possible in manufacturing and beyond.

Robotics in Medicine and Surgery

In the domain of healthcare, robotic arms are transforming medicine and surgery, offering unprecedented precision and control. You're now seeing surgical robotics playing a critical role in operating rooms worldwide. These advanced machines allow surgeons to perform minimally invasive procedures with remarkable accuracy. Imagine a robot-assisted surgery where the surgeon guides robotic arms to make tiny, precise movements that the human hand couldn't match. Surgical robotics can reduce recovery times and minimize risks for patients.

But it's not just about surgery. Robotic arms are also making strides in rehabilitation, where devices are designed to aid recovery by mimicking natural human movements. They help patients regain strength and motor skills after injuries or surgeries. For instance, you might find a patient using a robotic exoskeleton that supports limbs and promotes healing.

Consider these remarkable applications:

- Surgical Robotics: Enhancing surgical precision and reducing patient recovery times.

- Rehabilitation Devices: Assisting patients in regaining strength and mobility with robotic support.

- Remote Procedures: Allowing surgeons to perform operations from afar, expanding access to specialized care.

These innovations highlight how robotic arms are reshaping the landscape of healthcare, enhancing both surgical outcomes and patient rehabilitation.

Entry Into Aerospace Applications

Imagine the vast expanse of space and the challenges it presents. In the aerospace industry, traditional human capabilities face limitations, which is where aerospace robotics comes into play. You can envision robotic manipulation as a game-changer, offering precision and reliability in environments that humans find inhospitable or unreachable. As you think about these technological marvels, consider their ability to perform tasks with remarkable dexterity, from handling fragile equipment to executing complex operations that demand pinpoint accuracy.

In aerospace applications, robotic arms are crucial. They bridge the gap between human ingenuity and the harsh realities of space, allowing for innovation beyond Earth's boundaries. Picture a robotic arm delicately assembling parts of a satellite or conducting repairs on an aircraft. These robots aren't just tools; they extend human reach and improve our ability to investigate further.

Aerospace robotics also aids in testing and prototyping new technologies, ensuring safety and efficiency before human deployment. With robotic manipulation, you achieve feats that redefine what's possible in aerospace, from developing advanced aircraft to pioneering new frontiers. This entry into aerospace applications marks a significant leap in the utilization of robotic arms, setting the stage for future investigation and innovation.

Robotic Arms in Space Missions

Robotic arms have become indispensable in a variety of space missions. They're essential for tasks that human astronauts find too risky or impossible to perform. By using space robotics, you can improve mission efficiency and safety. Robotic manipulators, like those on the International Space Station (ISS), assist in construction, maintenance, and even scientific experiments.

When you think of robotic arms in space, consider these important roles:

- Satellite Deployment and Retrieval: They can launch satellites into orbit or retrieve and repair them.

- Construction and Maintenance: Space robotics are key for assembling large structures like space stations.

- Sample Collection: They help collect samples from other planets or asteroids, contributing to scientific research.

Imagine controlling a robotic manipulator from Earth, directing it to perform precise movements in a zero-gravity environment. These robotic systems have transformed how we investigate space, allowing for remote handling of equipment and reducing the need for human spacewalks. The famous Canadarm on the Space Shuttle and its successor, Canadarm2 on the ISS, exemplify the evolution of space robotics. In space missions, robotic arms are not just tools; they're your extended hands, reaching into the unknown to bring back knowledge.

Future Prospects and Innovations

As we look ahead, the future of robotic arms in space exploration promises remarkable advancements and innovations. You'll see autonomous control systems becoming more prevalent, allowing robotic arms to perform complex tasks with minimal human intervention. Artificial intelligence will improve these systems, enabling real-time feedback and predictive maintenance, guaranteeing that any potential issues are addressed before they become essential.

Collaborative robots, or cobots, will work alongside astronauts, improving human-robot interaction and efficiency in space missions. These cobots will be designed with modular design principles, allowing for easy customization and repair. Smart manufacturing techniques will incorporate advanced materials that make robotic arms lighter yet stronger, boosting their performance in the harsh conditions of space.

As we integrate these technologies, ethical considerations will come to the forefront. You'll need to guarantee that the autonomy of robotic arms doesn't compromise human safety or lead to unforeseen consequences. Balancing innovation with responsibility will be vital. By addressing these challenges, robotic arms will not only revolutionize space exploration but also set a precedent for their use in multiple industries on Earth, paving the way for a future where humans and robots work seamlessly together.