The Evolution of Robotic Welding Systems in Industrial Manufacturing

Robotic welding systems have greatly changed industrial manufacturing since the 1960s. You'll find that their rise began in automotive production during the 1970s. By the 1980s, innovations like programmable logic controllers improved their capabilities. The 1990s brought advanced sensors, allowing for real-time adjustments and better quality control. Today, these systems feature increased precision through AI and machine learning, enhancing efficiency and reducing waste. As you investigate further, you'll uncover how the latest technologies and trends continue to shape the future of these systems in manufacturing contexts.

Historical Overview of Robotic Welding

Robotic welding has come a long way since its inception in the 1960s, when the initial industrial robots started making their mark in manufacturing. You might not realize how crucial these early innovations were, but they set the stage for significant welding milestones throughout the decades. As you investigate the automation timeline, you'll see that by the 1970s, robotic welding began to gain traction, particularly in the automotive industry, where efficiency and precision were paramount.

The introduction of programmable logic controllers in the 1980s allowed robots to handle more complex welding tasks, further solidifying their role in production lines. By the 1990s, advancements in sensors and software led to smarter robots capable of real-time adjustments, enhancing quality control and reducing waste.

Fast forward to the 21st century, and you'll find that robotic welding systems are now commonplace in numerous industries, from aerospace to electronics. As you reflect on this historical overview, you'll recognize that each milestone in robotic welding has contributed to a more efficient, reliable, and precise manufacturing landscape, paving the way for innovations that continue to shape the future of the industry.

Early Innovations in Welding Technology

In the early 20th century, groundbreaking advancements in welding technology laid the foundation for modern manufacturing processes. You'd find that innovations like arc welding and gas welding transformed how industries approached metal joining. These welding techniques became vital for fabricating everything from automobiles to bridges, allowing for stronger and more durable constructions.

As you investigate this period, you'll notice that the use of historical materials, such as steel and aluminum, played a significant role. The introduction of these materials expanded the possibilities of what could be built. With techniques evolving, welding became more efficient and effective, reducing labor costs and increasing productivity.

You might also appreciate how early innovations led to the development of specialized equipment, like the initial welding machines, which made it easier for workers to perform tasks that were previously labor-intensive and hazardous. As these welding techniques gained popularity, they opened the door for further advancements, ultimately leading to the automated systems we see today. By understanding these early innovations, you can better appreciate the trajectory of welding technology and its impact on industrial manufacturing.

Key Components of Robotic Systems

The evolution of welding technology has naturally led to the integration of robotic systems in industrial manufacturing. At the heart of these systems are robotic arms, which provide precision and flexibility for numerous welding techniques. You'll find that these arms are often equipped with sensor technology, enabling them to detect and adapt to their environment, enhancing the general efficiency of the welding process.

Motion control plays a vital role in ensuring that robotic arms move accurately and smoothly, while power sources provide the necessary energy for welding operations. Moreover, effective material handling systems work in tandem with robotic arms to manage the positioning and movement of components.

Programming languages are fundamental for configuring robotic systems, allowing you to customize their functions based on specific tasks. User interfaces streamline interaction, making it easier to set parameters and monitor performance. Safety standards are also critical, ensuring that these systems operate without posing risks to workers or equipment. Finally, system integration allows for seamless communication between different components, maximizing productivity and reliability in manufacturing processes.

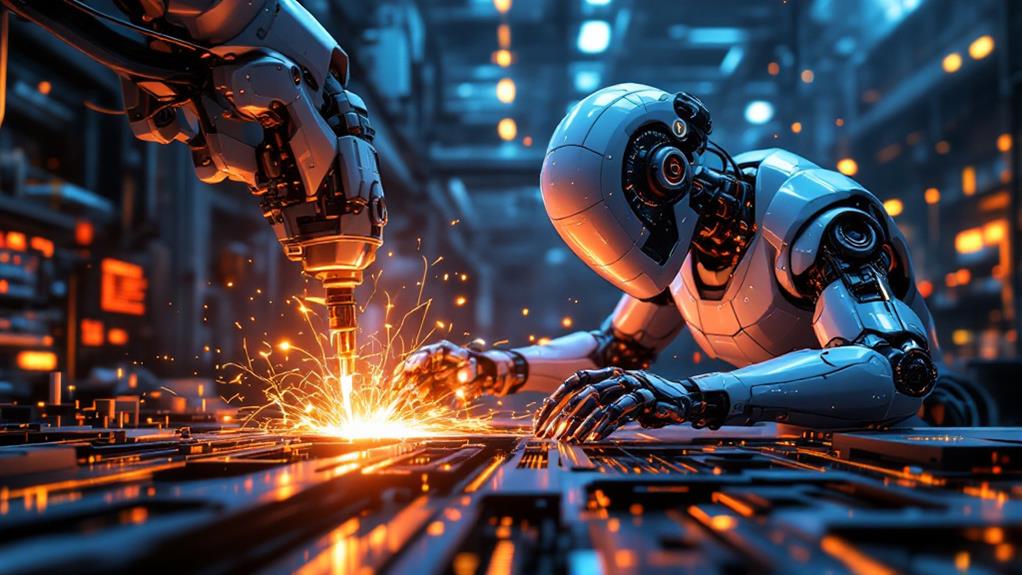

Advancements in Automation and Control

Recent innovations in automation and control have transformed the way welding systems operate in industrial settings. You'll find that advanced sensor technologies improve precision and adaptability, allowing robots to respond in real-time to changing conditions. These innovations foster process optimization, ensuring that each weld meets stringent quality standards.

User-friendly programming interfaces simplify the setup and adjustment of robotic systems, reducing the need for extensive user training. As a result, operators can quickly become proficient and confident in managing complex welding tasks. Incorporating robust safety protocols is now standard, ensuring that both personnel and equipment remain protected during operation.

Moreover, system integration capabilities mean that robotic welders can seamlessly connect with other machinery and software, streamlining workflows and improving productivity. Implementing effective maintenance strategies further minimizes downtime, helping to keep your operations running smoothly. You can also utilize performance metrics to analyze system efficiency, enabling continuous improvement and informed decision-making.

Integration of AI and Machine Learning

AI and machine learning's integration into robotic welding systems is transforming industrial manufacturing. You're now witnessing a shift where intelligent algorithms improve decision-making systems, leading to enhanced productivity and efficiency. With real-time monitoring and adaptive learning capabilities, robotic welders can adjust their operations dynamically, ensuring peak performance throughout the production process.

Consider these key benefits:

- Predictive Maintenance: By analyzing data analytics, systems can foresee potential failures before they occur, reducing downtime and costs.

- Process Enhancement: AI-driven insights allow for continuous improvement in welding techniques, improving both speed and quality assurance.

- Quality Assurance: Automated systems can detect defects in real-time, ensuring that only high-quality products reach the market.

This integration not only streamlines operations but also empowers you to make more informed decisions. The combination of data analytics and machine learning means your robotic welding systems can learn from past experiences, leading to higher efficiency and lower waste. Embracing these advancements will position your manufacturing processes at the forefront of innovation, setting you apart in a competitive landscape.

Current Trends in Robotic Welding

As manufacturing adopts the benefits of AI and machine learning, current trends in robotic welding are becoming increasingly evident. One notable trend is the rise of cobots collaboration, where robots and human workers unite to improve productivity and safety. This approach not only raises efficiency but also allows for smoother changes in the workforce, helping workers develop new skills alongside advanced machines.

In numerous industry applications, you'll find a growing emphasis on safety protocols, ensuring that both robots and personnel operate in secure environments. The demand for cost efficiency drives companies to adopt groundbreaking welding techniques, which can greatly reduce production times and waste while maintaining high-quality standards.

Material compatibility is another key focus, as advancements in technology enable robotic systems to work with a wider range of materials, adapting to specific project needs. With increasing market demand for tailored solutions, customization options in robotic welding systems are also on the rise. These trends reflect a shift toward more intelligent, adaptable manufacturing processes that not only meet current challenges but also pave the way for future advancements in the industry.

Benefits of Robotic Welding Systems

In the current competitive manufacturing landscape, robotic welding systems offer a multitude of benefits that can greatly improve your operations. These systems not only improve precision, but they also address the pressing labor shortage by providing flexible applications that adapt to different projects. This adaptability allows you to maintain consistent quality, even with a limited workforce.

Here are some key advantages you can expect:

- Cost efficiency: By reducing labor costs and minimizing errors, robotic welding systems help you save both time and money.

- Improved safety: Automating dangerous welding tasks keeps your workers safe from potential hazards, creating a healthier work environment.

- Increased productivity: With the ability to operate continuously, robots can greatly raise your output without sacrificing quality.

Additionally, robotic welding systems help in reducing waste and improving skill levels among your workforce. As employees interact with these advanced machines, they acquire new skills, further advancing your comprehensive operational capabilities. Embracing robotic welding not only modernizes your manufacturing process but also positions you for sustained success in a rapidly evolving industry.

Challenges and Limitations Faced

While robotic welding systems offer significant advantages, there are challenges and limitations that manufacturers must consider. You might face safety concerns, as the integration of robots into your workspace can increase risks if not managed properly. Furthermore, skill shortages can hinder your ability to operate and maintain these systems, making it essential to invest in training for your workforce.

Cost implications can also be intimidating; the initial investment in robotic systems and ongoing maintenance challenges can strain your budget. In addition, the complexity of programming these robots can lead to delays in production if your team lacks the necessary expertise. Adaptability issues arise when your production needs change, as not all robotic systems can handle diverse materials or new welding techniques.

Material limitations can restrict the types of projects you can undertake, while workspace constraints might prevent you from installing larger robotic systems. Balancing these challenges with the benefits of robotic welding requires careful planning and consideration, ensuring that you enhance efficiency without compromising safety or quality. Addressing these factors will help you navigate the complexities of robotic welding in your manufacturing environment.

Future Prospects and Developments

The landscape of robotic welding systems is evolving rapidly, driven by advancements in technology and increasing demand for precision and efficiency in industrial manufacturing. As you look ahead, consider how these systems will adapt to sustainability initiatives and regulatory considerations, shaping the future of your industry.

You'll likely see significant trends, such as:

- Technology convergence: Integrating AI and IoT with robotic systems improves their capabilities.

- Workforce adaptation: As automation increases, you'll need to focus on skill development to prepare your team for advanced roles.

- Market expansion: New applications will emerge, providing opportunities for cost efficiency and safety improvements.

These developments will lead to a more efficient manufacturing process, allowing you to meet the growing demands for precision while maintaining safety standards. Embracing these changes means investing not just in technology, but also in your workforce. Improving skills will be crucial as you adapt to new systems and processes. With the right approach, you can utilize these advancements to drive growth and maintain a competitive edge in a rapidly evolving market.

Impact on Industrial Manufacturing

Robotic welding systems greatly transform industrial manufacturing by improving efficiency and precision in production processes. You'll notice a significant productivity improvement, as these systems operate at a speed and consistency that manual welding can't match. This leads to quality consistency across your products, reducing defects and rework.

With the integration of robotic systems, there's also an emphasis on safety improvements. You'll find that automation minimizes human exposure to hazardous conditions, creating a safer workplace. As a result, workforce adaptation becomes crucial, requiring employees to develop new skills to manage and maintain these advanced technologies. This shift fosters skill development that can increase overall job satisfaction.

Cost efficiency is another major impact. By optimizing your supply chain and reducing labor costs, robotic welding systems contribute to significant energy savings and overall operational expenses. As you adopt these innovations, you'll experience a more agile manufacturing process, allowing you to respond quickly to market demands.