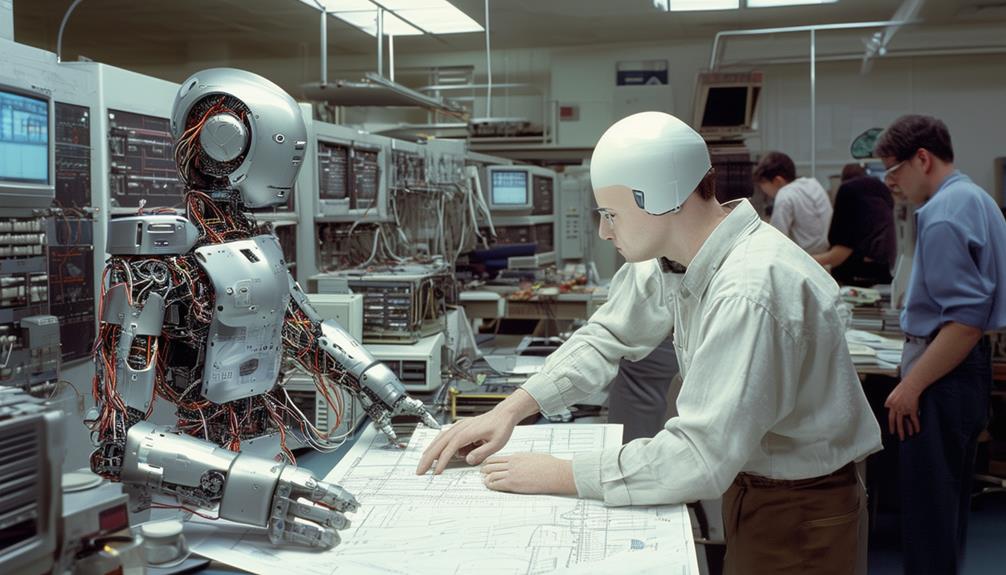

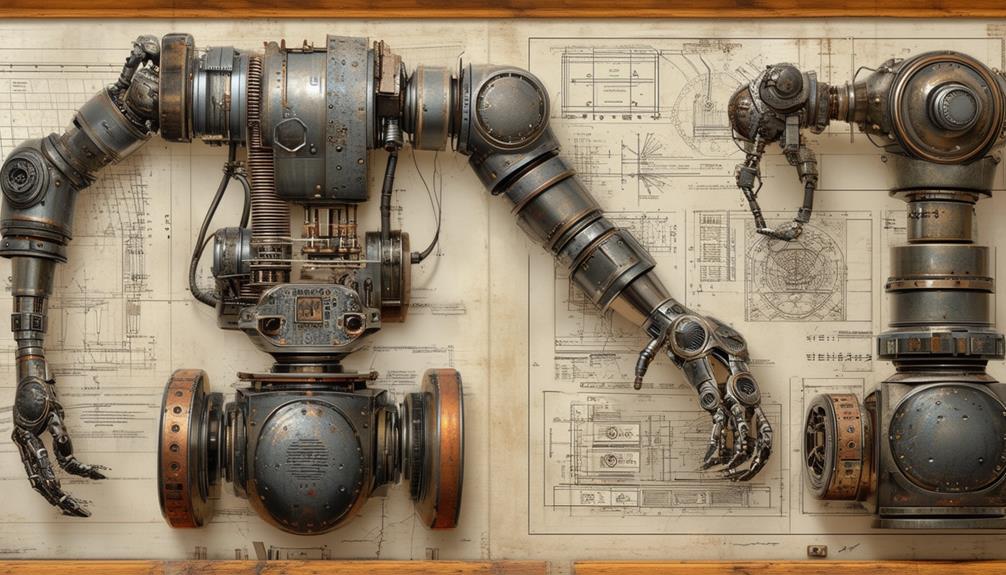

The Development of Early Robot Arms and Manipulators

Discover how the inception of early robot arms and manipulators, such as Unimate and the Tentacle Arm, revolutionized industry standards. Pioneers like George Devol and Joseph Engelberger spearheaded innovations that not only enhanced efficiency but also redefined safety and precision in manufacturing. What motivated these visionaries, and how did their creations lay the groundwork for today's advanced robotics? By exploring these origins, you'll gain insights into the technological milestones that have shaped contemporary industrial practices. Curious about the enduring legacy of these early advancements?

Invention of the First Robotic Arm

In 1954, George Devol invented the pioneering robotic arm, Unimate, which revolutionized industrial automation. This initial robotic arm, designed specifically for General Motors, was engineered to handle the hot and hazardous task of metal die casting. The advent of a machine capable of performing such a physically demanding and dangerous job with precision and consistency had a profound impact.

Devol's innovation extended beyond the invention of the robotic arm; he also co-founded Unimation with Joseph Engelberger. Unimation became the world's first robot company, dedicated to producing and selling this groundbreaking technology. By integrating Unimate into production lines, they achieved a significant milestone in robotics history. The introduction of Unimate showcased the potential of robotics to transform industrial processes, making them safer and more efficient.

This development laid the foundation for modern industrial robotics, with automation systems evolving from Devol's original concept. The creation of the initial robotic arm underscored the vital role that robotics could play across various industries, paving the way for future advancements. As we reflect on today's automated world, it is important to recognize that it all began with George Devol's visionary Unimate.

George Devol's Contributions

George Devol's contributions to robotics are monumental, with his invention of Unimate serving as a cornerstone for modern industrial automation. In 1954, Devol developed Unimate, the first digitally operated and programmable robotic arm designed to automate manufacturing processes. This groundbreaking innovation marked a pivotal moment in the industrial revolution, transforming how assembly line tasks were executed.

Devol's introduction of Unimate was not merely the creation of a new machine but a revolutionary shift in the industrial sector. Prior to Unimate, assembly lines relied heavily on human labor, which was both time-consuming and error-prone. Unimate, however, could perform repetitive tasks with precision and efficiency, significantly reducing human error and boosting overall productivity.

One of Unimate's earliest major successes was its integration into General Motors' production line, showcasing the practical applications of robotic arms in industry and paving the way for widespread adoption. Devol's work established the foundational principles for the use of robotic arms across various industries globally, making him a true pioneer in robotics. His vision and innovation continue to shape modern automation technologies, propelling the industrial revolution forward.

Unimate's Industrial Impact

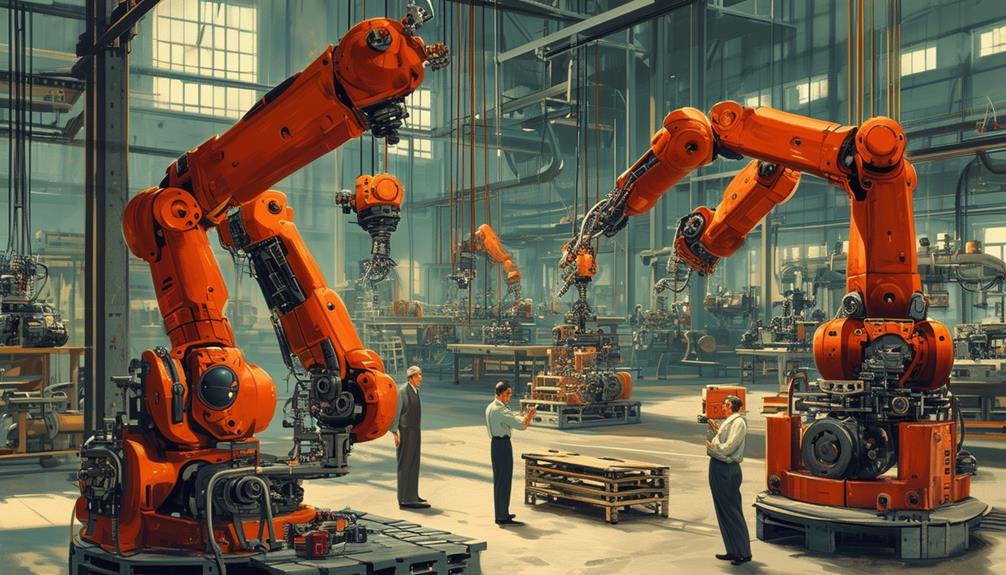

Unimate's industrial impact can be seen in its transformation of manufacturing processes by automating tasks such as welding and painting. This allowed human workers to focus on more complex duties, significantly improving production efficiency and laying the groundwork for modern industrial robotics.

Revolutionizing Manufacturing Processes

Unimate, the pioneering industrial robot arm, revolutionized manufacturing by automating repetitive and hazardous tasks. First deployed at General Motors' plant, Unimate fundamentally changed car production, boosting efficiency and safety by taking over dangerous duties from human workers.

Key impacts of Unimate include:

- Efficiency: Streamlined production lines, significantly increasing output.

- Precision: Delivered consistent quality in welding and material handling.

- Safety: Reduced workplace injuries by managing hazardous tasks.

- Scalability: Enabled mass production, making automation accessible across industries.

- Innovation: Paved the way for smart factories and modern robotics.

Unimate's introduction marked a pivotal moment in manufacturing history. It sparked widespread adoption of robotic arms across various sectors, transforming global manufacturing operations and laying the groundwork for smart factories and Industry 4.0 technologies. This shift demonstrated the potential of robotic arms to enhance precision, speed, and safety, setting new standards for future advancements in automation.

Automating Repetitive Tasks

The automation of repetitive tasks in manufacturing has revolutionized production efficiency and set new industry standards. The introduction of Unimate marked a pivotal moment in the auto industry, where robotic arms began replacing human labor for tasks such as welding and material handling. Unimate demonstrated precision and efficiency, flawlessly performing tasks that were monotonous and physically demanding for humans.

Unimate excelled in automating processes like die casting and spot welding. These industrial robots didn't require breaks or rest, enabling continuous operation and significantly enhancing the speed and consistency of manufacturing processes. For companies, this translated into increased productivity and substantial cost savings.

The success of Unimate paved the way for the widespread adoption of industrial robotics across various sectors. Modern production lines now feature robot arms as a standard, tirelessly performing repetitive tasks with unmatched accuracy. This shift to automation has redefined manufacturing and established new benchmarks for industrial robots. With Unimate, the era of robotic efficiency began, forever transforming the landscape of production.

Enhancing Production Efficiency

By revolutionizing industrial production, Unimate set new standards for efficiency, precision, and safety in manufacturing processes. Unimate, the pioneering industrial robot arm, transformed the automotive industry in the late 1950s. Its ability to perform repetitive tasks with unparalleled accuracy not only sped up production lines but also greatly reduced human error.

The introduction of robotic arms like Unimate allowed tasks to be completed consistently and at a pace that humans couldn't match. This led to higher productivity and a safer working environment, as robots took over dangerous and monotonous tasks.

Key impacts of Unimate on production efficiency include:

- Increased throughput: Robotic arms operated tirelessly, leading to faster production times.

- Improved precision: Robots performed tasks with exacting accuracy, reducing waste.

- Enhanced safety: Robots handled hazardous tasks, protecting workers from potential harm.

- Global adoption: Unimate's success in Europe and Japan accelerated the worldwide acceptance of industrial robotics.

- Legacy of innovation: Unimate paved the way for future advancements in automated manufacturing.

Unimate didn't just boost production efficiency; it redefined the possibilities of industrial robotics, leaving a lasting legacy in manufacturing.

Marvin Minsky's Tentacle Arm

In 1968, Marvin Minsky introduced the Tentacle Arm at MIT, showcasing a groundbreaking approach to robotic arm design. Unlike the rigid, industrial robotic arms of that era, Minsky's Tentacle Arm featured a flexible design resembling a tentacle, marking a significant leap in robotic technology.

The Tentacle Arm utilized pneumatic actuators to achieve fluid, versatile movements. This flexibility allowed it to perform manipulation tasks that were previously challenging or impossible for more rigid robotic arms. It can be seen as a precursor to today's advanced, adaptable robotic systems.

Minsky's innovation wasn't just about creating a flexible arm; it was about exploring new possibilities in robotic manipulation. The Tentacle Arm demonstrated that effective robotic design doesn't have to mimic human joints and limbs, opening new avenues for robotic applications and designs.

Joseph Engelberger's Role

Joseph Engelberger's visionary leadership revolutionized industrial automation through the introduction of the Unimate robotic arm. By founding Unimation, Engelberger didn't just create a company; he ignited a transformation in manufacturing. His tireless efforts to promote and sell the inaugural industrial robot arm, the Unimate, demonstrated his unwavering belief in the potential of robotics.

Here's how Engelberger's work made a lasting impact:

- Introduction of the Unimate: The world's first industrial robot arm, revolutionizing factory automation.

- Commercialization of Robotics: Unimation played a pivotal role in making robotic arms commercially viable.

- Global Adoption: Engelberger's vision led to the widespread use of robotic arms in industries worldwide.

- Innovative Leadership: Known as the 'Father of Robotics,' his groundbreaking contributions have shaped the field.

- Industrial Automation: His work laid the foundation for modern robotic manufacturing processes.

Through Unimation, Joseph Engelberger set the stage for the future of industrial automation. His pioneering efforts not only changed how factories operated but also spurred further advancements in robotic technology. Engelberger's legacy lives on as industries continue to adopt and evolve with the robotic arms he championed.

Advancements in Robotic Manipulators

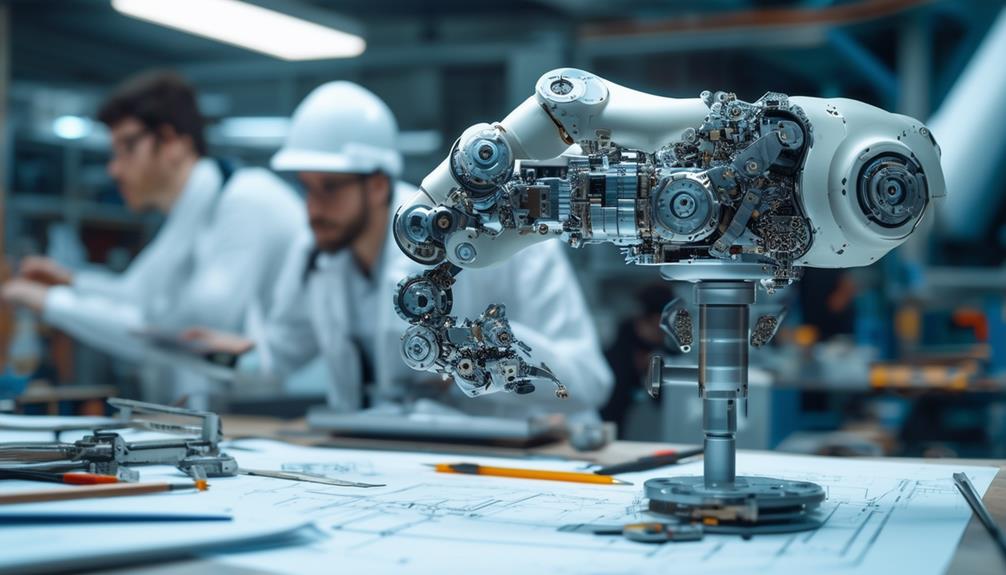

Technological advancements in robotic manipulators have significantly enhanced automation and efficiency across various industries. Modern robotic arms have evolved considerably since George Devol's initial invention in 1954, becoming more versatile, precise, and intelligent.

The integration of artificial intelligence and machine learning has revolutionized robotic manipulators. These advanced arms can now adapt to complex tasks by learning from their environment, making them indispensable in manufacturing, healthcare, and even space exploration. Collaborative robots, or cobots, work alongside humans, enhancing productivity while maintaining safety.

Advancements in materials science and engineering have made robotic arms more agile. Lightweight yet strong materials enable these manipulators to handle delicate tasks with precision, reducing downtime and increasing efficiency. This is particularly impactful in industries requiring high precision, such as electronics and pharmaceuticals.

Furthermore, advancements in sensor technology allow today's robotic manipulators to perform highly intricate operations. They can sense and respond to their environment in real-time, ensuring tasks are completed with utmost accuracy. These innovations have expanded the capabilities of robotic arms, solidifying their role as essential tools in modern automation.

Legacy of Early Robot Arms

The legacy of early robot arms, such as George Devol's Unimate, laid the groundwork for today's advanced automation technologies. When the Unimate debuted in the late 1950s, it was a groundbreaking innovation that revolutionized industrial automation. As the pioneering industrial robot arm, the Unimate demonstrated how machines could take over repetitive and hazardous tasks like welding and material handling, significantly enhancing efficiency and safety in manufacturing environments.

Unimate's introduction marked the beginning of a new era in industrial automation. George Devol, along with Joseph Engelberger, founded Unimation in 1956, the company that would bring this innovative technology to industries worldwide. The success of the Unimate showcased the potential for robotic arms to become essential components in various sectors, leading to widespread adoption and continuous advancement.

The impact of these early robot arms continues to be felt today. Here's how:

- Increased productivity: Robotic arms handle tasks faster and more consistently than humans.

- Enhanced safety: Robots take on dangerous jobs, reducing workplace injuries.

- Precision and accuracy: Modern robots deliver high levels of precision in manufacturing processes.

- 24/7 operations: Robots can work continuously without breaks.

- Reduced costs: Automation lowers labor costs and improves efficiency.

Thanks to the Unimate and the visionaries behind it, the field of industrial automation continues to evolve and thrive.

Conclusion

Early pioneers like George Devol and Joseph Engelberger revolutionized industries with robotic arms such as Unimate and the Tentacle Arm. Their innovations laid the groundwork for today's advanced, AI-driven manipulators. Due to their pioneering work, modern robots are more efficient, precise, and safe, transforming numerous sectors. The legacy of these early developments continues to propel progress, making the future of automation extraordinarily promising. Embrace the possibilities they have unlocked.