How Texas Automates: Industrial Robots & Smart Farms

Texas automation spans a fast-growing robotics ecosystem and rapidly evolving agricultural technology. You’ll find collaborative robots transforming manufacturing while addressing labor shortages across Dallas-Fort Worth and Houston. In agriculture, more farms are using connected equipment and data tools, with adoption expected to keep climbing through the 2030s. Smart tractors, automated packing systems, and robotic harvesting platforms now support Texas’s massive agricultural economy. The integration of industrial robotics and precision farming continues reshaping the Lone Star State’s economic landscape.

Texas Robotics: Current Industry Landscape and Market Position

As Texas strengthens its position in the national industrial automation arena, the state’s robotics market has become an integral component of the broader U.S. landscape. You’ll find major corporations like Tesla and General Motors driving automation adoption across manufacturing facilities statewide. The state’s robotics infrastructure development benefits from strong academic research centers and cross-industry collaborations that foster innovation in specialized applications. Rather than hinging on one “Texas-only” market-share statistic, Texas’s importance shows up in where robots are being deployed—especially across automotive, electronics, and aerospace supply chains. Government support initiatives have accelerated Industry 4.0 implementation, especially in industrial hubs like Houston and Dallas. This strategic backing, combined with private investment in smart factory technologies, positions Texas to capitalize on continued national growth in robotics and factory automation.

Salary Trends for Industrial Robotics Workers Across the Lone Star State

Texas’s burgeoning robotics market has created diverse employment opportunities with equally varied compensation packages. You’ll find substantial geographic salary disparities across major hubs, with Austin often trending higher than many other Texas metros depending on role and specialization. Experience dramatically influences earnings, with market ranges varying widely by employer, credentialing, and whether the job is technician, integrator, or engineer. Most workers cluster around mid-range pay bands, though top earners can break into six figures in specialized engineering and leadership roles. Contract work impacts compensation considerably, contributing to more pay variability in large metro markets. Machine operators typically earn less than controls engineers and robotics engineers, who command higher wages due to the skill requirements. The sector follows national growth trends, with robotics compensation generally moving upward with demand, specialization, and automation expansion. In practice, training and demonstrated hands-on competency often matter as much as job title when employers set pay.

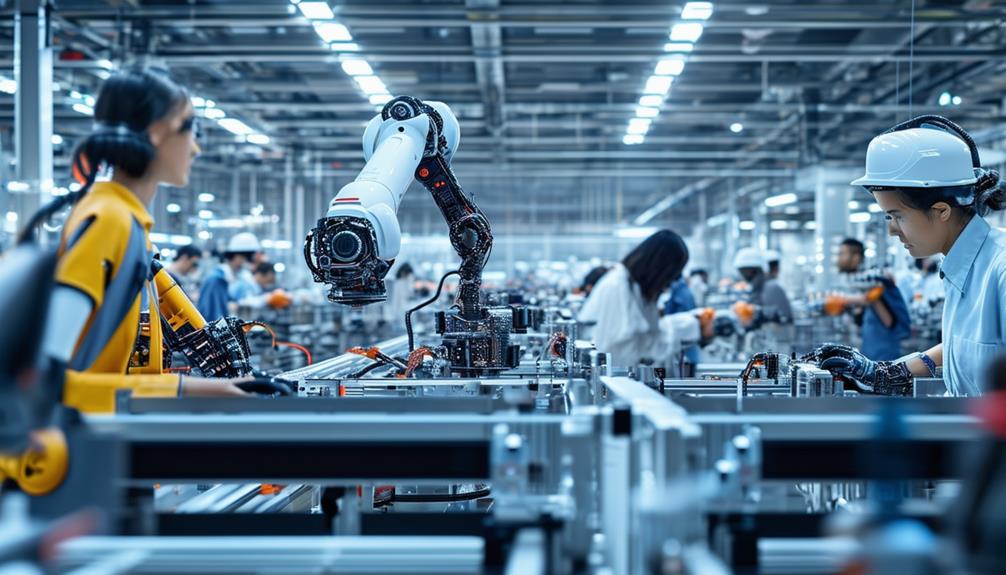

The Rise of Collaborative Robots in Texas Manufacturing

Why are collaborative robots revolutionizing manufacturing floors across Texas? As the cobot market expands globally, you’ll find these machines transforming production environments while addressing labor shortages in key metros. Cobots are reshaping workforce transformation dynamics through:

- Safety-first design - 6-axis arms with force-limited features can reduce injury risks while often lowering the need for extensive safety fencing

- Labor optimization - Workers shift from repetitive tasks to higher-skill operations, improving job satisfaction

- Economic efficiency - SMEs increasingly adopt cobots to improve production quality and flexibility while reducing operational costs

Local manufacturers can explore these innovations at regional trade events and vendor showcases held across North Texas and the Houston area. Despite their advantages, cobot safety considerations remain pivotal, requiring thorough risk assessments before implementation.

Smart Farming Revolution: How Texas Agriculture Embraces Automation

Across the vast agricultural landscape of Texas, a technological revolution quietly transforms traditional farming into a data-driven, increasingly automated enterprise. You’ll find more farms using connected machinery, sensors, and software dashboards to plan irrigation, fertilization, and harvest timing. Smart tractors and automated equipment can minimize resource use while boosting labor productivity. Real-time moisture sensors and AI-assisted management tools allow you to monitor multiple operations simultaneously through digital dashboards, helping farmers adapt to arid West Texas conditions more efficiently. This automation isn’t just about efficiency—it’s reshaping the industry’s structure. As some operations scale up, sustainability can improve through precision irrigation and variable-rate fertilization. The integration of robotic harvesting platforms and specialized grippers helps delicate crops receive consistent handling with less waste. Over time, automation continues moving from “pilot projects” to everyday farm workflows.

Precision Agriculture Technologies Transforming Texas Farms

View this post on Instagram

How drastically has technology reshaped farming in the Lone Star State? You’re witnessing a shift where precision agriculture strengthens Texas production through better targeting and better timing, with tech adoption rising unevenly by crop type and region. Texas farmers now leverage:

- GPS guidance and autosteering systems that improve accuracy while reducing overlap and fuel use

- Drones and UAVs for crop monitoring, helping detect stress and pest pressure earlier through imaging

- Predictive analytics and field models that simulate outcomes and support planning, especially in high-variability operations

This robotics-enabled sustainability can reduce chemical use through targeted applications and optimize irrigation based on soil moisture data. That means better water stewardship while maintaining productivity across Texas’s diverse agroecosystems.

Texas Universities Leading Robotics Innovation and Research

View this post on Instagram

While farmers harness technology in their fields, the brain trust behind Texas’s robotics momentum operates on university campuses throughout the state. UT Austin’s Texas Robotics integrates multiple labs focused on autonomy and human-robot interaction, while Texas A&M’s robotics work spans multiple engineering departments and applied research centers. These institutions form an interconnected ecosystem where tomorrow’s automation experts develop skills in control theory, machine learning, and advanced materials. That talent pipeline helps keep Texas competitive in robotics innovation touching agriculture, industrial automation, medical devices, and logistics. You’ll also find specialized robotics education programs at University of Houston-Clear Lake and across the UT System that support industry upskilling. Meanwhile, programs at UT San Antonio and other campuses help translate research into practical applications for manufacturing and urban infrastructure.

Employment Opportunities and Challenges in Texas Robotics Sector

Despite Texas being a major employer for robotics and automation roles, the state presents a complex picture of opportunity and challenge for those seeking careers in the field. The market can be competitive, and postings can fluctuate based on capital investment cycles in manufacturing, energy, and logistics. If you’re considering a Texas robotics career, note these key factors:

- Salary variability - Pay can differ sharply by city, specialization, and whether you’re in integration, maintenance, or engineering

- Training pathways - Technician and certification programs can provide faster entry points than engineering routes, depending on goals

- Continuous learning - Evolving skills in PLCs, sensors, ROS, machine vision, and safety standards demand ongoing education

However, several Texas cities offer strong opportunity density, especially where manufacturing, logistics, and research clusters overlap. In many roles, practical troubleshooting ability is the fastest way to stand out.

Comparing Texas Robotics Growth to National and Global Trends

Texas’s robotics landscape exists within a broader context of national and global automation trends, presenting both parallels and distinctions worth examining. While global markets move quickly, U.S. growth is often steadier and tied to reshoring, productivity goals, and labor constraints. You’ll find Texas leveraging regional automation incentives that mirror national pushes toward manufacturing efficiency, with a distinctive emphasis on energy-adjacent automation and large-scale logistics. The state’s investment drivers include strong electronics and automotive supply chains alongside agriculture-focused technology adoption. Texas companies increasingly adopt collaborative robots and AI-integrated systems, aligning with broader Industry 4.0 transformation. At the same time, workforce development and availability of integrators play a major role in how fast deployments scale.

Key Industries Driving Robotics Adoption in Texas

Several distinct sectors across the Lone Star State are powering the robotics revolution, with manufacturing, electronics, agriculture, and industrial automation leading the charge. You’ll find companies like Komatsu and John Deere pushing automation across equipment, logistics, and production support systems. State initiatives and workforce development programs can accelerate adoption, particularly for SMEs through manufacturing assistance and training resources. Workshops and regional modernization programs help businesses plan automation without relocating operations out of state. Three industries showing remarkable robotics integration:

- Advanced manufacturing, where automation supports output, consistency, and safety

- Agriculture, where smart farming tools address labor needs while improving precision and sustainability

- Electronics and industrial assembly, where robotics supports repeatability, inspection, and high-throughput production

Future Outlook: Texas Automation Beyond 2025

The automation landscape in Texas is poised for continued transformation after 2025, with four key technological shifts reshaping industrial operations across the state. You’ll see more smart factory buildouts as large facilities adopt longer “dark” production windows with fewer manual handoffs. As labor shortages persist, cobots will become standard fixtures in manufacturing, creating new roles focused on maintenance, integration, and analytics. Remote process monitoring will evolve through AI integration with industrial IoT systems, supporting self-optimizing lines and more practical digital twins. The rollout of faster connectivity and private wireless networks will improve machine-to-machine communication, supporting tighter control loops for sensors, PLCs, and SCADA environments. Texas manufacturers embracing these technologies are positioned to gain advantages through flexibility, reduced downtime, and improved operational efficiency.