How Servo Motors Power Precision Movements in Robotics

You'll uncover that servo motors are essential for powering precise movements in robotics. They work through a closed-loop system, providing instant feedback for exact motion control. With built-in feedback mechanisms like encoders, servo motors make micro-adjustments in real-time, ensuring accuracy in tasks ranging from surgery to drone navigation. They come in different types, including digital and continuous rotation, each suited for specific robotic needs. Their precision in torque control and minimal maintenance make them ideal for complex tasks. As you investigate further, you'll find how these motors improve robotic efficiency across a range of applications.

Understanding Servo Motor Basics

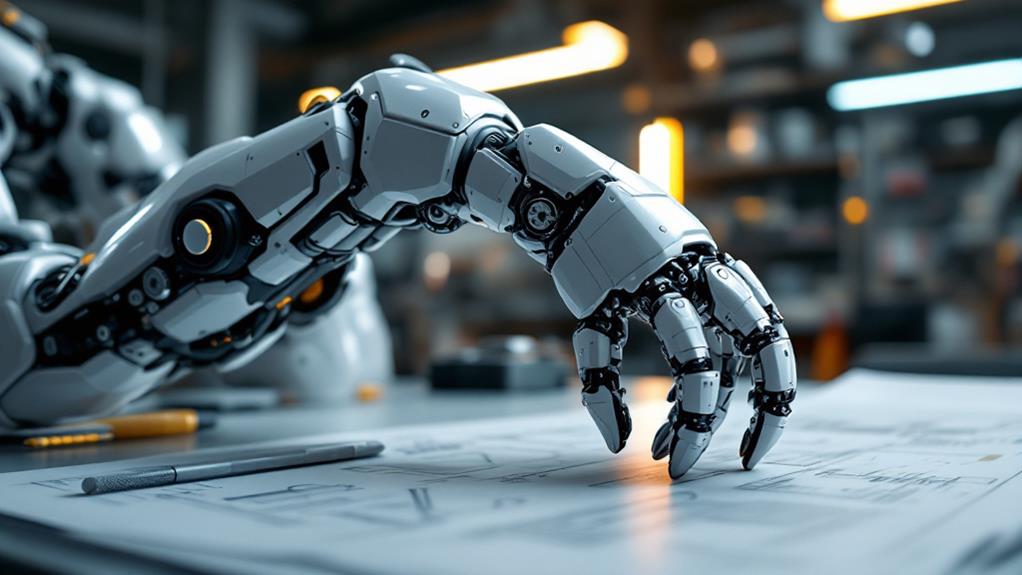

Servo motors are a fundamental component in the domain of robotics, providing precision and control vital for diverse applications. When you're exploring the basics of servo motors, you'll quickly see how important servo control and feedback systems are. These motors operate using a closed-loop system, which means they constantly receive feedback to adjust their output and maintain the desired position or speed.

Imagine you're trying to move a robotic arm to pick up an object. The servo motor uses feedback systems to measure its position, ensuring it moves precisely where you want it. This dynamic adjustment is what sets servo motors apart, as they can correct errors in real-time, maintaining accuracy.

You'll find that servo control involves sending a signal to the motor, dictating its position. The motor's internal feedback system, often an encoder or potentiometer, sends data back to the controller about its current state. This feedback loop is vital because it allows the motor to make micro-adjustments, ensuring smooth and precise movements.

Understanding these basics helps you appreciate why servo motors are indispensable in robotics, offering the control and adaptability needed for complex tasks.

Types of Servo Motors

You'll often encounter different types of servo motors in robotics, each designed to meet specific needs and applications. Analog servos and digital servos are the primary categories. Analog servos are typically simpler and less expensive, making them ideal for projects where cost is a priority. They work well for tasks requiring basic positional control. However, if you need faster response times and more precise control, digital servos are the way to go. They process signals more quickly, offering higher performance for demanding tasks.

For applications requiring continuous rotation, continuous rotation servos are vital. Unlike standard servos that provide limited angular movement, these can rotate 360 degrees, making them perfect for wheels or conveyor belts. If your project demands high torque or low backlash, consider industrial servos. They're built for strength and precision, handling heavy loads effectively.

Miniature servos are another option, especially useful in small-scale robotics. They provide adequate torque in a compact form, ideal for tight spaces or lightweight designs. By understanding these types, you can choose the right servo motor to improve your robotic projects' efficiency and precision.

Also check out Micro Servo as well.

Key Components and Functions

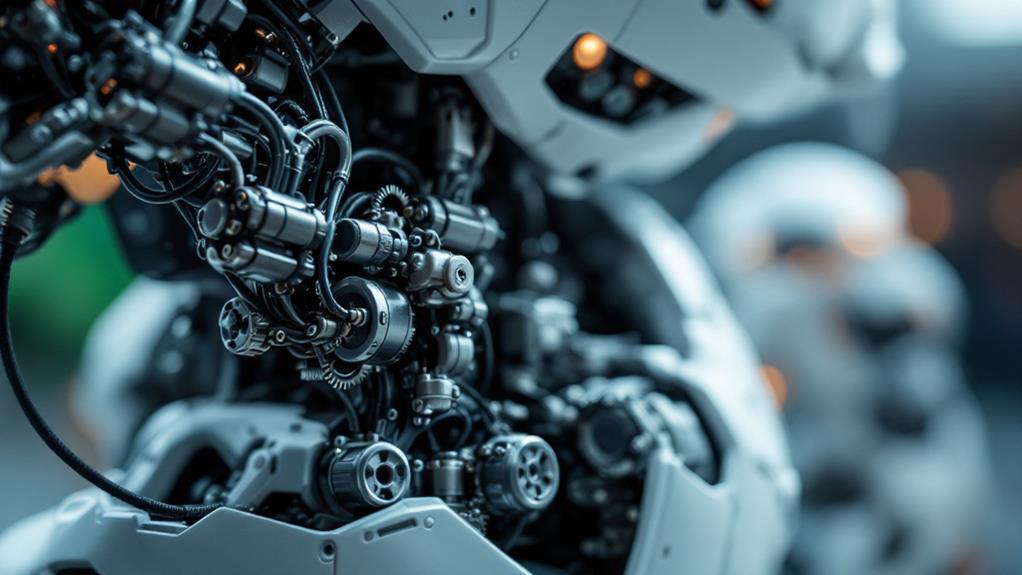

Understanding the different types of servo motors lays the groundwork for exploring their key components and functions. Servo motors rely on sophisticated control systems to manage precise movements. These systems use signal processing to interpret commands and adjust the motor's output. Feedback mechanisms, like encoders or potentiometers, play a significant role by providing real-time data on the motor's position and speed. This feedback enables effective motion tracking and guarantees the motor moves accurately as directed.

Torque ratings are fundamental for determining the motor's ability to handle loads. Higher torque ratings mean the servo can move heavier or more resistant objects. Gear configurations within the motor influence its speed and strength, allowing for different levels of force and precision based on the task.

Calibration techniques are critical for optimizing a servo motor's performance. They guarantee the motor's movements align with its intended path, reducing errors and enhancing precision. Performance metrics are used to evaluate how well a servo motor meets its operational requirements, such as response time and accuracy. By understanding these components and functions, you can better appreciate how servo motors achieve the precise movements necessary in robotics.

Applications in Robotics

In robotics, servo motors frequently play a vital role in bringing machines to life with precise and controlled movements. When you think about robotic arms, these motors are fundamental for enabling smooth, accurate motions, regardless of assembling products or conducting intricate tasks. In the domain of automated machinery, servo motors guarantee that each component operates with the exact synchronization needed for high efficiency and reliability.

Consider drones navigation, where precision is key. Servo motors help maintain stability and control during flight, allowing drones to perform complex maneuvers and tasks with ease. In precision agriculture, these motors enable machines to plant, harvest, and manage crops with extreme accuracy, optimizing yield and reducing waste.

When it comes to robotic surgery, you're looking at a field where precision is non-negotiable. Servo motors allow surgical robots to perform delicate procedures with a level of accuracy that's beyond human capability, enhancing patient outcomes. Finally, in industrial automation, servo motors drive the efficiency of production lines, improving speed and accuracy while reducing the need for manual intervention. By integrating these motors, you can boost the performance of diverse robotic applications across multiple industries.

Advantages of Servo Motors

Servo motors offer several compelling advantages that make them indispensable in robotics and automation. Their energy efficiency guarantees that your robotic systems run effectively without wasting power, which is vital in applications where energy consumption matters. With precise torque control, servo motors allow you to manage force output accurately, enabling delicate tasks or those requiring significant power. Speed regulation is another key benefit, as servo motors can adjust speed seamlessly, catering to different operational demands.

Feedback systems in servo motors provide real-time data about position, speed, and torque, allowing you to make immediate adjustments and maintain peak performance. This leads to improved performance metrics, making them suitable for high-precision tasks. Cost considerations are also favorable; while servo motors might initially seem more expensive, their longevity and efficiency often lead to lower total expenses.

Maintenance requirements for servo motors are generally minimal, saving you both time and money over the product's lifespan. However, you should be aware of size limitations, as servo motors might not fit every application. Despite this, their compact design often provides the perfect balance between size and power, making them a flexible choice in many robotics applications.

Future Trends in Robotics

Robotics is rapidly evolving, and several key trends are shaping its future. You'll notice that autonomous guidance is at the forefront, transforming how robots move and interact with their environments. These advanced systems enable robots to independently map, analyze, and traverse complex terrains without human intervention. Whether it involves delivering packages or maneuvering a factory floor, autonomous guidance empowers robots to perform tasks with incredible precision and efficiency.

Machine learning is another groundbreaking trend, allowing robots to learn from data and experiences to improve over time. This capability means that robots can adapt to new situations, optimize their performance, and even anticipate problems before they occur. Imagine a world where robots in healthcare learn the nuances of patient care or manufacturing robots fine-tune their operations for maximum productivity—machine learning makes this possible.

Looking ahead, you'll find that these trends are not isolated but interconnected. The fusion of autonomous guidance with machine learning is setting the stage for even more sophisticated robotic systems. As these technologies advance, you'll see robots becoming more intuitive, capable of performing complex tasks across different sectors, from logistics to healthcare, thereby reshaping industries and daily life.