How Robotic Manipulators Work: Precision in Handling Delicate Objects

Robotic manipulators work by combining advanced sensors and control systems to handle delicate objects with precision. You'll find that diverse types, such as articulated and soft robots, mimic human movements to adapt to different tasks. Their grippers are designed to apply just the right amount of force, ensuring items aren't damaged. Tactile and vision sensors provide real-time feedback, enhancing their ability to manipulate fragile materials accurately. These systems continuously learn and adjust for peak performance. If you're curious about specific applications or how they're advancing, there's plenty more to investigate.

Overview of Robotic Manipulators

Robotic manipulators are adaptable devices designed to perform a range of tasks with precision and efficiency. You'll find these machines in numerous industries, where they excel at handling delicate objects and repeating tasks with consistent accuracy. Their ability to mimic human-like movements gives them remarkable robotic dexterity, allowing you to automate complex processes that would be difficult or time-consuming for humans.

By employing advanced sensors and control systems, robotic manipulators can adapt to different tasks, ensuring that they maintain a high level of automation efficiency. This means you can boost productivity while reducing the chances of error. Whether you're assembling parts, packaging products, or conducting precision surgeries, these manipulators can perform with a level of reliability that's hard to match.

Moreover, their flexibility enables you to reprogram them for new tasks as your needs evolve, making them an invaluable asset in fast-paced environments. Ultimately, investing in robotic manipulators can lead to significant improvements in both speed and quality, allowing you to focus on more strategic aspects of your operations while they handle the repetitive tasks with ease.

Key Components and Mechanisms

To understand how robotic manipulators function effectively, it is essential to examine their key components and mechanisms. Each part plays a significant role in ensuring precision and safety when handling delicate objects. Here are four important components you'll encounter:

- Gripper Designs: These are tailored to securely grasp different objects. Creative designs, like soft or adaptive grippers, help minimize damage to fragile items.

- Actuating Mechanisms: These systems convert energy into motion. Electric, hydraulic, or pneumatic actuators provide the necessary force and movement for manipulation.

- Control Interfaces: These allow you to communicate with the manipulator. User-friendly interfaces enable precise control over movement and positioning.

- Feedback Systems: Incorporating force sensing and kinematics analysis, these systems provide real-time data on the manipulator's performance, enhancing accuracy and safety features.

Material selection is just as significant, as it impacts durability and the manipulator's ability to handle different loads. By understanding these components, you can appreciate how robotic manipulators achieve high precision and reliability in delicate tasks.

Types of Robotic Manipulators

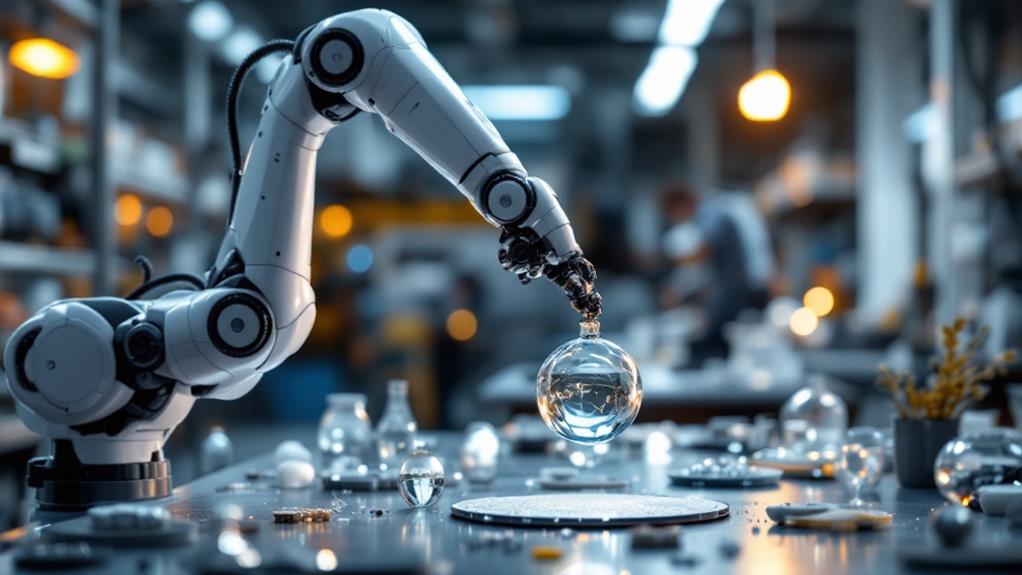

Understanding the different types of robotic manipulators can improve your grasp of how they're designed for specific tasks. Each type has unique features that cater to distinct applications. For instance, articulated robots mimic human joints, making them ideal for complex movements. In contrast, parallel manipulators offer high precision and stability, often used in assembly lines.

Delta robots are another popular choice for tasks requiring speed and accuracy, especially in picking and placing items. If you need a different range of motion, cylindrical manipulators provide flexibility in vertical and horizontal movements. Cartesian robots, with their straightforward linear motion, excel in tasks like packaging and machining.

Spherical manipulators allow for rotational movements within a specific range, making them suitable for tasks that require a wide field of motion. Humanoid arms, designed to replicate human-like dexterity, are increasingly used in applications that require fine manipulation, like surgery. Finally, soft robotics introduces a new dimension, using flexible materials to handle delicate objects without damaging them. Each of these robotic manipulators plays an essential role in enhancing efficiency and precision across different industries.

Sensors for Precision Handling

When you're working with robotic manipulators, sensors play an important role in ensuring precision handling. These sensors enable the robot to interact delicately with objects, improving its ability to perform tasks accurately. Here are four key types of sensors you'll find in robotic manipulators:

- Tactile Sensors: These sensors provide force feedback, allowing the manipulator to detect the pressure applied to an object, which is vital for grip optimization.

- Vision Systems: By incorporating advanced object recognition capabilities, vision systems help the robot identify and position itself relative to different items.

- Haptic Feedback Sensors: These sensors improve compliance control, giving the operator a sense of touch and helping the robot adjust its movements based on real-time data.

- Sensor Fusion: This technology combines inputs from multiple sensors, increasing accuracy and reliability in handling delicate tasks.

With these sensors working together, robotic manipulators can achieve high precision in their operations, making them indispensable in fields requiring careful handling of fragile objects. By understanding these components, you can appreciate how they contribute to the effectiveness of robotic systems.

Control Algorithms and Programming

Effective control algorithms and programming are key to harnessing the capabilities of sensors in robotic manipulators. You need to implement control strategies that allow the robot to understand its environment and respond accurately. By utilizing programming languages like Python or C++, you can develop adaptive algorithms that adjust the robot's behavior based on real-time feedback from its sensors.

Incorporating feedback systems is fundamental, as they provide the necessary data for motion planning and guarantee the manipulator can handle delicate objects without causing damage. You'll want to focus on creating robust user interfaces that make it easy to monitor and control the manipulator's operations.

Simulation tools play a critical role in refining your algorithms before deployment. They allow you to visualize how the manipulator will behave in different scenarios, helping you make informed decisions about motion planning. Real-time adjustments are imperative, too; they guarantee your robotic manipulator can adapt to unexpected changes in its environment, maintaining precision during tasks. By mastering these elements, you can considerably improve the efficiency and reliability of robotic manipulators in handling delicate objects.

Applications in Various Industries

Exploring the applications of robotic manipulators across diverse industries reveals their transformative impact on efficiency and precision. These advanced machines are altering how tasks are performed, ensuring accuracy and speed that humans often can't match.

Here are some key applications:

- Food Packaging: Robotic manipulators streamline packaging processes, ensuring items are packed quickly and hygienically, which is essential in the food industry.

- Surgical Assistance: In healthcare, these robots assist surgeons with precision in delicate procedures, enhancing patient outcomes and reducing recovery times.

- Electronics Assembly: Robotics play an important role in the assembly of electronic components, handling tiny parts with care and accuracy, minimizing the risk of damage.

- Art Handling: In the art world, robotic manipulators are used to transport and install artworks safely, preserving their integrity during handling.

Additionally, robotic manipulators are making strides in agricultural automation, laboratory research, material sorting, and aerospace manufacturing. By integrating these systems, industries can achieve higher productivity levels while maintaining the quality and safety of their products.

Advantages of Robotic Manipulators

Robotic manipulators offer several notable advantages that improve operational efficiency and effectiveness across industries. One of the most compelling benefits is their safety features, which minimize workplace accidents and protect workers from hazardous tasks. With an intuitive user interface, you can easily program and control these machines, reducing the training requirements for operators.

Their ergonomic design guarantees that tasks are performed without straining human workers, improving comfort and productivity. Furthermore, robotic manipulators boast impressive scaling capabilities, allowing you to adapt them to diverse production needs seamlessly. This adaptability factor means they can effectively handle delicate objects without compromising precision.

Cost efficiency is another major advantage. By automating processes, you can considerably reduce labor costs and improve throughput. Plus, well-defined maintenance protocols help guarantee longevity and reliability, minimizing downtime. Altogether, these advantages make robotic manipulators a strategic investment for any industry looking to improve productivity while maintaining high safety standards. Embracing this technology can transform your operational processes, leading to measurable improvements in both performance and safety.

Challenges in Delicate Handling

While robotic manipulators provide significant advantages, handling delicate objects presents unique challenges that can complicate their effectiveness. You'll find that dealing with fragile materials requires careful consideration of numerous factors to guarantee successful manipulation. Here are four key challenges you should keep in mind:

- Grip Strength: Finding the right grip strength is critical. Too much force can damage delicate items, while too little can result in dropping them.

- Material Properties: Understanding the material properties of the objects you're handling is fundamental. Different materials react differently to pressure, temperature, and environmental factors.

- Task Variability: Each task may require different handling techniques. Adapting to this variability can be tricky and may necessitate advanced programming.

- Human Interaction: Integrating human interaction into robotic systems poses challenges. Confirming safety protocols are in place is crucial to prevent accidents, especially when humans and robots work closely together.

Future Trends in Robotics

Increasingly, advancements in technology are shaping the future of robotics, paving the way for more sophisticated and adaptable systems. You'll likely see autonomous robots becoming integral in numerous sectors, from healthcare to manufacturing. These robots will not only perform tasks independently but will also improve human-robot collaboration, making workplaces safer and more efficient.

Soft robotics is another trend gaining traction, as these systems use advanced materials to mimic human dexterity. This allows for delicate handling of fragile objects, something traditional robots struggle with. Machine learning will play a significant role, enabling robots to learn from their environments and improve their performance over time.

Moreover, adaptive control techniques will help robots adjust their movements based on real-time feedback, ensuring precision in tasks. However, as you welcome these innovations, it is important to reflect on ethical considerations surrounding autonomous technologies. Balancing the benefits of robotic dexterity with potential risks will be crucial as robotics continues to evolve. Ultimately, the future of robotics holds exciting possibilities, and it is up to you to navigate this rapidly changing landscape.