How Hydraulic Systems Work in Robots: Key Components and Uses

When you're exploring how hydraulic systems power robots, you'll see they harness fluid dynamics to create strong and precise movements. These systems use pressurized oil to power hydraulic cylinders and actuators, transforming pressure into motion. The primary components include hydraulic pumps, directional and flow control valves, and pressure regulation units. Each part is designed for peak power transmission and control. You find hydraulic systems excelling in tasks that demand heavy lifting or precise manipulation, often seen in industrial settings like material handling and welding. There are advancements that improve these systems' efficiency and sustainability worth uncovering.

Understanding Hydraulic Power in Robotics

Harnessing the power of hydraulics in robotics involves understanding how fluid dynamics can be used to generate movement. By tapping into hydraulic energy, you can create robots that accomplish tasks with precision and strength. The basic principle revolves around using incompressible fluids—usually oil—to transmit power. When you apply force to a fluid, it moves through the system, transferring energy to different components, enabling motion.

In hydraulic systems, pressurized fluid is the lifeblood, driving actuators and motors. This is where fluid dynamics plays a vital role. By controlling the flow rate and pressure of the fluid, you manipulate how much force and speed your robot can exert. This ability to fine-tune movement and force makes hydraulics ideal for applications requiring heavy lifting or precise control, like in construction or surgical robots.

Understanding hydraulic energy goes beyond just knowing how it moves through a system. You need to grasp how changes in pressure and flow affect performance. By mastering these concepts, you can design robots that are not only powerful but also efficient and reliable, ensuring they meet the demands of complex tasks with ease.

Essential Hydraulic System Components

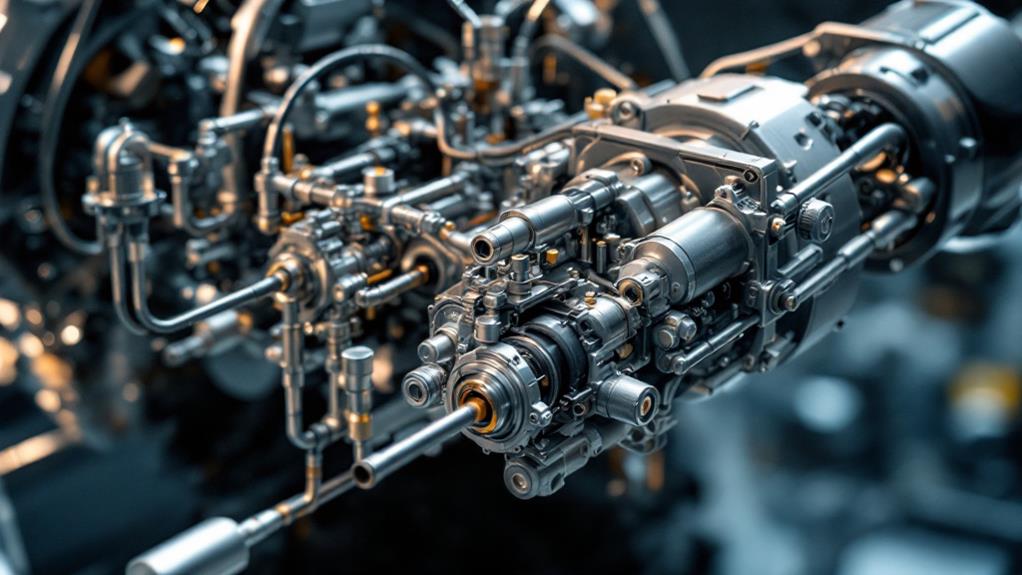

To build an effective hydraulic system for robots, you'll need to understand its core components. At the heart of any hydraulic system lies the hydraulic circuit design. This intricate network consists of pipes, hoses, and valves working together to channel fluid under pressure. The fluid dynamics principles govern how this fluid moves, guaranteeing efficient energy transmission and precise control.

Start with hydraulic cylinders, which convert fluid pressure into linear motion. These cylinders are essential for moving robot arms or other components with strength and precision. Next, consider the hydraulic fluid itself—usually oil, chosen for its ability to transmit power effectively while lubricating and cooling the system.

Valves play an important role in controlling fluid flow and direction. Directional control valves determine the path of the fluid, while pressure relief valves prevent potential overloads by releasing excess pressure. Check valves guarantee fluid flows in the right direction, preventing backflow that could damage your system.

Role of Hydraulic Pumps in Robots

In any hydraulic system, pumps play an fundamental role by converting mechanical energy into hydraulic energy. In robots, these pumps are significant for powering movements with precision and strength. They guarantee that the hydraulic fluid flows to the actuators, enabling the robot to perform tasks like lifting, gripping, or maneuvering. You'll find that when a hydraulic pump operates efficiently, the entire system benefits from improved hydraulic efficiency, reducing energy consumption and wear.

To keep your robotic system running smoothly, regular pump maintenance is crucial. This involves checking for leaks, verifying the pump is clean, and inspecting seals and connections for wear. By maintaining the pump, you not only prolong its lifespan but also prevent unexpected downtime that could disrupt operations. A well-maintained pump contributes to consistent performance, allowing your robot to execute tasks reliably.

When selecting a hydraulic pump for a robot, consider factors like flow rate and pressure requirements to match the robot's operational needs. Different types of pumps, such as gear or piston pumps, offer varying levels of efficiency and performance. Choosing the right pump guarantees peak hydraulic efficiency, maximizing your robot's capabilities while minimizing energy usage.

Importance of Valves in Robotics

Valves play an essential role in the hydraulic systems of robots by controlling the flow and direction of hydraulic fluid. They come in a range of valve types, each serving a unique purpose. For instance, flow control valves adjust the fluid rate to guarantee your robot's movements are smooth and precise. Meanwhile, pressure regulation valves maintain the right pressure levels, preventing damage to components and enhancing hydraulic efficiency.

Safety mechanisms are also fundamental to valve design. They help you avoid accidents by automatically stopping fluid flow if abnormal conditions arise. This guarantees your robotic system operates safely under differing circumstances. Regular valve maintenance is important to keep these systems functioning correctly. By inspecting and cleaning valves, you prevent blockages and leaks that could disrupt your robot's performance.

Valves are key in integrating actuators, as they direct hydraulic fluid to these components, enabling them to perform their tasks. Signal systems typically control valves, allowing you to program specific movements and functions into your robot. Understanding the significance of valves in robotics guarantees you design and maintain efficient, safe, and responsive hydraulic systems in your robots.

Function of Hydraulic Actuators

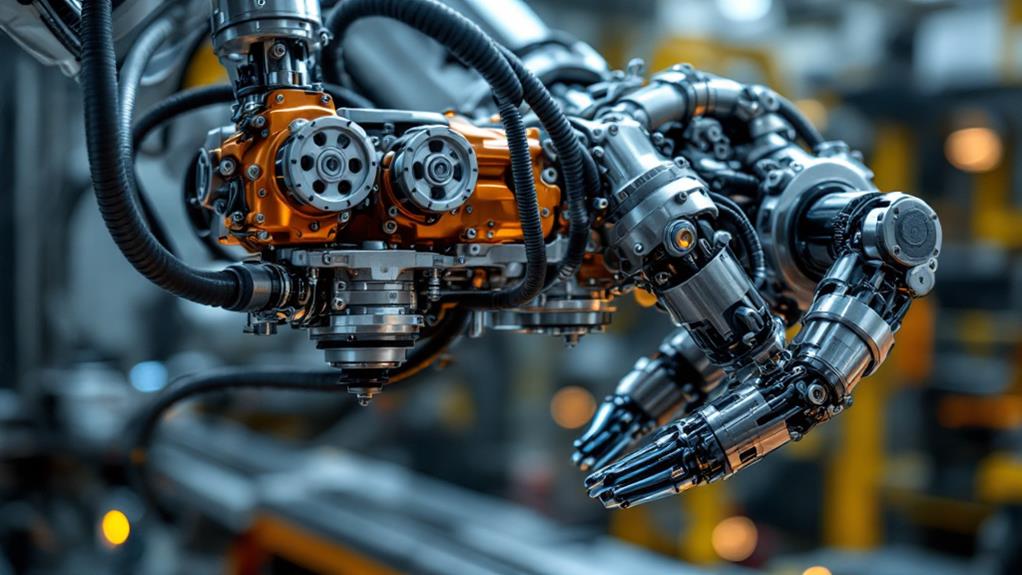

Hydraulic actuators are the powerhouse behind a robot's movements, converting hydraulic energy into mechanical motion. They provide the force and precision a robot needs to perform tasks across different industries. You'll find distinct hydraulic actuator types, each serving unique functions. Here are three key aspects to reflect upon:

- Types of Hydraulic Actuators: You'll primarily encounter linear and rotary actuators. Linear actuators convert hydraulic energy into linear motion, perfect for pushing or pulling tasks. Rotary actuators, on the other hand, provide rotational movement, useful for joints and rotating components.

- Actuator Performance Metrics: When evaluating hydraulic actuators, you'll want to think about force output, speed, and efficiency. The force output determines how much weight or resistance the actuator can handle, while speed affects how quickly it can move. Efficiency is essential for ensuring minimal energy loss during operation.

- Applications in Robotics: Hydraulic actuators are indispensable in robotics applications requiring high force and precision. They're used in industrial robots for tasks like welding, material handling, and even in surgical robots where precision is paramount.

Understanding these components' roles helps you appreciate how hydraulic actuators drive robotic efficiency and effectiveness in different settings.

Hydraulic Fluids and Their Properties

When you're working with hydraulic systems in robotics, selecting the right hydraulic fluid is critical for ideal performance. The fluid you choose directly impacts how efficiently your system operates and its overall lifespan. One crucial property to take into account is fluid viscosity. It measures how easily the fluid flows, which can affect the speed and responsiveness of your robot's movements. A fluid that's too thick might cause sluggish operation, while one that's too thin could lead to leaks and reduced efficiency.

Pressure stability is another key factor. Your hydraulic fluid must maintain its performance under different pressure conditions. If it can't handle high pressures, your system may suffer from cavitation or even component failure. This is especially vital in robotics, where precision and reliability are non-negotiable.

You also need to take into account the fluid's compatibility with system materials. Some fluids can cause corrosion or degrade seals, leading to leaks and maintenance issues. Furthermore, operating temperature ranges should match the fluid's thermal properties to prevent overheating or freezing. By carefully selecting a hydraulic fluid with the right fluid viscosity, pressure stability, and material compatibility, you guarantee your robotic systems function smoothly and effectively.

Applications in Industrial Robotics

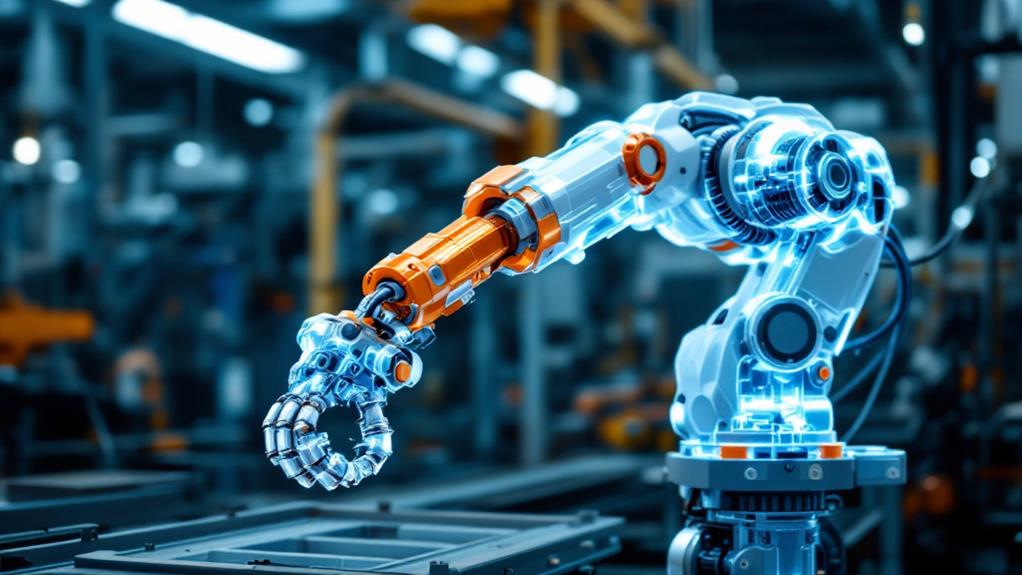

In the domain of industrial robotics, hydraulic systems play a vital role by providing the power and precision needed for complex tasks. These systems are fundamental in environments where robotic automation demands high force and accuracy. Hydraulic efficiency is key, as it determines how effectively a robot can perform its duties. With the right system in place, you can expect improved performance, reliability, and cost-effectiveness.

Consider these three applications of hydraulic systems in industrial robotics:

- Material Handling: Hydraulic robots can lift heavy objects with ease, making them perfect for tasks like stacking, sorting, and transporting goods in warehouses or manufacturing settings.

- Welding and Assembly: In assembly lines, hydraulic robots guarantee precise movements, enabling them to weld or assemble components with minimal error, thereby increasing productivity and maintaining quality.

- Machining and Cutting: Hydraulic systems provide the necessary force for cutting through tough materials. They also maintain consistent pressure, allowing for clean, accurate cuts every time.

Advancements in Robotic Hydraulics

As robotic technology advances, the capabilities of hydraulic systems are evolving rapidly to meet new demands. You're witnessing a shift towards smart hydraulics, which integrate sensors and digital controls to improve robotic efficiency. These smart systems allow for precise motion control, adapting in real-time to varying loads and operational conditions. They're not just about brute force anymore; they're about finesse and adaptability.

Incorporating smart hydraulics into robots means you can achieve higher levels of accuracy and reliability in tasks that require complex movements. For instance, in manufacturing environments, these systems enable robots to handle delicate materials without causing damage. It's all about refining performance and reducing energy consumption, making operations more sustainable.

Robotic efficiency is further improved by advancements in materials and design. Lightweight hydraulic components reduce the total weight of robots, enhancing speed and agility. Additionally, advancements in fluid dynamics allow for more efficient power distribution, minimizing losses and improving system responsiveness.

Staying updated with these advancements means you can optimize robotic systems for a range of applications, from industrial automation to healthcare robotics. Embracing these innovations will certainly keep you at the forefront of technological progress.