Houston’s Space-Age Robots and Automation in Industry

Houston's robotics scene thrives thanks to NASA's Johnson Space Center, which supports research and partnerships that help drive advanced automation technologies. You'll find space-inspired robots now influencing manufacturing, energy, healthcare, and logistics across the city's diverse industries.

Local companies are adopting collaborative robots, autonomous systems, and AI-assisted solutions to boost productivity and address labor challenges. Houston's unique ecosystem connects aerospace expertise with industrial applications, creating a robotics shift you'll want to explore further.

NASA's Johnson Space Center: Houston's Robotics Innovation Hub

Tucked within NASA's Johnson Space Center (JSC) are specialized teams where the agency's robotic future takes shape. You'll find busy workspaces filled with evolving prototypes and software systems designed to enable human exploration beyond Earth.

The Robotic Systems Technology Branch supports development of remotely controlled and autonomous systems that align with NASA's Artemis efforts and longer-term exploration goals. These technologies are no longer framed around a "2024 return" timeline—instead, they support a phased campaign that includes lunar surface mobility and technology pathways that can inform future Mars missions. Among these innovations are next-generation Lunar Terrain Vehicle concepts and test units that help evaluate mobility designs intended to assist astronauts during planned Moon missions.

JSC's robotics work spans hardware, software, simulation, and integration, and many of these systems double as technology testbeds. The result is a pipeline of ideas that can translate from space environments to terrestrial industry needs.

From Space to Industry: How Houston's Robotic Technologies Drive Economic Growth

While NASA's robotics innovations capture imaginations with their space applications, Houston's terrestrial economy can benefit from this technological crossover. The city's manufacturing base and industrial services ecosystem increasingly leverage automation to remain competitive while navigating workforce and operational pressures.

You'll find the impact of this technology push evident in three key areas:

- Economic diversification through initiatives like the East End Maker Hub, projected to generate an estimated $153 million in annual economic impact

- Small business robotics adoption creating new job opportunities even as many routine tasks across industries become increasingly automatable

- Artificial intelligence applications transforming traditional sectors, including back-office processes and service operations that rely on speed and consistency

This dual-edged technological shift requires careful navigation as Houston balances innovation with workforce adaptation in its evolving industrial landscape. With manufacturing employment changing over time due to technology, globalization, and cyclical demand, the city faces steady pressure to prepare workers for an increasingly automated future.

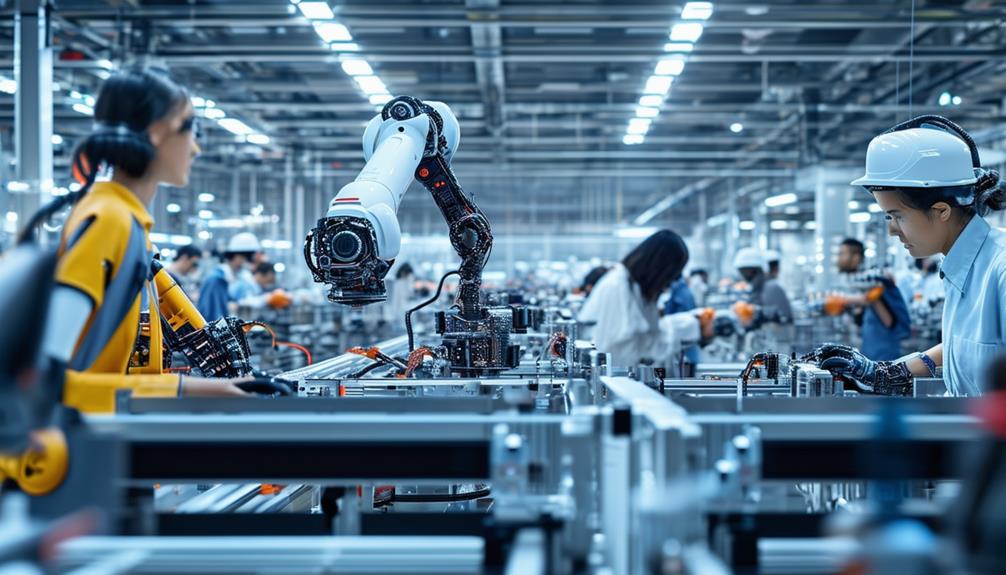

The Rise of Collaborative Robots in Houston's Manufacturing Landscape

The manufacturing floors of Houston tell a compelling story of transformation as collaborative robots emerge as key players in the city's industrial evolution. You'll find these cobots across Houston's diverse industrial landscape, with adoption often tied to measurable improvements like cycle-time gains and reduced strain on workers in repetitive tasks.

As Texas remains a major state for robotics-related jobs and industrial hiring, Houston manufacturers are embracing this technology—particularly in energy-adjacent manufacturing, electronics, and life sciences supply chains. The growth projections for the collaborative robotics market underscore the significance of this shift in manufacturing. Cobot adoption factors vary by payload requirements, with many deployments focused on lighter loads for precision work and safe human-robot collaboration.

Local robotics training programs are expanding to support this growth, preparing workers to operate alongside these machines that address labor shortages while enhancing productivity across Houston's manufacturing ecosystem—from aerospace-adjacent work to biomedical applications.

Automation Solutions Transforming Houston's Energy and Petrochemical Sectors

As innovation accelerates across Houston's industrial landscape, you'll find automation technologies reshaping the energy and petrochemical sectors that form the backbone of the region's economy. Enterprise AI governance frameworks increasingly guide implementation of these technologies across operations, enhancing efficiency while supporting compliance and risk controls.

The transformation includes:

- Predictive analytics and condition monitoring that can lower unplanned downtime and reduce costs, especially when paired with strong maintenance practices

- Industrial IoT systems with real-time monitoring expanding across facilities, improving visibility into equipment health and process stability

- Digital twins enabling virtual simulation of assets and operating scenarios for better planning and decision-making

You'll see this evolution at places like Schneider Electric's Energy Innovation Center in Houston, where digital solutions can be demonstrated through real-world industrial simulations. Industry experts also explore how these technologies shape customer expectations and ROI discussions through ongoing professional programming and industry seminars held across the region.

Engineering Talent Pipeline: Preparing Houston's Workforce for the Robotic Revolution

Houston's technological transformation extends beyond implementing systems to cultivating the human talent that powers them. The city's tech workforce is projected to keep growing, and Texas remains a leading state for robotics-related employment and engineering demand.

Local initiatives focus on reskilling displaced workers from traditional industries into robotics and automation roles, while educational institutions are enhancing STEM curricula with AI and automation components. Improving talent retention strategies has become critical as Houston competes with larger tech hubs for specialized engineers and experienced technicians.

Public-private partnerships are addressing workforce readiness through apprenticeships and industry-sponsored innovation labs. With robotics engineer salaries often landing in a broad range depending on specialty and experience, Houston offers competitive compensation while working to bridge gaps between academic training and practical industry requirements.

Addressing Labor Challenges Through Advanced Robotics and AI Systems

Facing labor shortages across critical industries, companies throughout Houston have turned to advanced robotics and AI systems as strategic solutions rather than mere technological upgrades. These technologies address the declining interest in physically demanding jobs while delivering productivity gains through consistent, repeatable operations.

Collaborative robots now represent a meaningful and growing share of automation demand, enabling safer human-robot partnerships while reducing physical strain. AI-integrated systems perform complex tasks like precision assembly and quality inspection, maintaining productivity despite skilled labor scarcity. Data-informed automation improves manufacturing flow, resulting in better workplace safety and more stable output. Recent industry reporting continues to show steady growth in cobot orders and deployments, reflecting the increasing importance of collaborative solutions.

You'll find Houston's automation landscape transforming rapidly as cobots and smart systems fill critical gaps without simply eliminating jobs—instead shifting workforce demand toward higher-skilled roles in programming, maintenance, and system integration.