Exploring Soft Robotics: New Materials and Flexible Designs

Imagine standing at the forefront of robotics, witnessing how soft robotics is revolutionizing the field with innovative materials and flexible designs. Silicone and elastomers have already made significant strides, offering unparalleled flexibility and resilience. Now, consider the impact of integrating advanced materials like hydrogels and shape-memory alloys. This combination not only enhances robot durability but also paves the way for novel applications in healthcare, exploration, and beyond. As these advancements redefine human-robot interactions and navigate complex environments, the possibilities for future discoveries expand exponentially.

Innovative Fabrics in Soft Robotics

In soft robotics, advanced fabrics like silicone and elastomers are revolutionizing the field by offering exceptional flexibility and pliability. These innovative materials enable soft robots to mimic biological systems, allowing for safer, more natural interactions with humans. Such materials make soft robots ideal for delicate tasks where traditional rigid robots might pose a risk.

For instance, in-space assembly and habitation on other planetary bodies benefit significantly from these materials. Soft robots can perform tasks such as bonding and de-bonding struts with precision and safety, much like assembling LEGO blocks. This capability is crucial in environments where human presence is limited or impossible.

Furthermore, the use of advanced fabrics in soft robotics broadens the range of applications. These robots can safely work alongside humans, making them suitable for tasks in healthcare, manufacturing, and disaster response. Their ability to adapt to various shapes and surfaces ensures they can handle tasks requiring a gentle touch.

Elastomers: Enhancing Flexibility

Elastomers play a crucial role in the flexibility of soft robotics due to their exceptional material properties. These polymers provide remarkable stretchability and durability, enabling robots to execute complex and gentle movements. Their application is leading to innovative solutions, making soft robots more adaptable and safer across various industries.

Advanced Material Properties

Ever wondered how soft robots achieve their remarkable flexibility and adaptability? The secret lies in the advanced material properties of elastomers. These materials, such as silicone and rubber, are crucial in the realm of soft robotics. By incorporating elastomers, soft robots can deform and adapt to various shapes and environments, providing the necessary flexibility for intricate tasks.

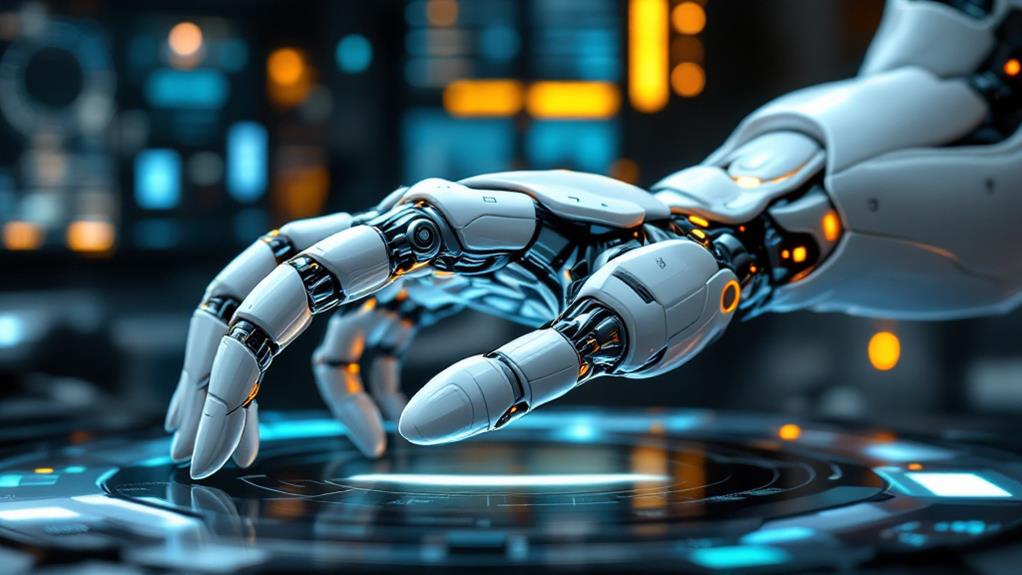

Elastomers offer a unique blend of flexibility and compliance, enabling soft robots to mimic the natural movements of living organisms. Picture a robotic hand gently grasping an object just like a human hand. This level of dexterity is achievable due to the exceptional properties of elastomers. They enable robotic components to bend, twist, and stretch without breaking, which is essential for interacting with delicate or irregular objects.

Additionally, elastomers are not just about flexibility; they also offer resilience. These materials provide durability and resistance to wear and tear, ensuring that soft robots can perform consistently over time. Whether maneuvering through tight spaces or handling repetitive motions, the durability of elastomers keeps soft robots functioning effectively. Embracing elastomers in soft robotics opens up a world of possibilities in flexible and adaptive designs.

Stretchability and Durability

Elastomers like silicone and rubber significantly enhance the flexibility and performance of soft robots due to their high stretchability and durability. These materials can deform and adapt to various shapes, allowing soft robots to perform tasks that rigid robots cannot. Elastomers enable robots to withstand bending, twisting, and stretching without losing structural integrity, thus accommodating repetitive movements and interactions without rapid wear.

These materials are particularly advantageous for tasks requiring precise movements. Their mechanical properties allow robots to mimic natural motions, making them ideal for applications where accuracy is crucial. For instance, a soft robot made from elastomers can gently grasp and manipulate objects, minimizing the risk of damage.

The wear resistance of elastomers ensures long-term performance, maintaining functionality even under constant use. This durability results in reduced maintenance and longer operational periods, making elastomers a cost-effective choice for soft robotics. Incorporating elastomers into designs not only boosts stretchability and flexibility but also significantly increases the lifespan and reliability of soft robots.

Innovative Applications Emergence

Soft robotics is transforming various industries by employing elastomers to enhance flexibility and adaptability in innovative applications. By integrating materials such as silicone and hydrogels, soft robots can replicate natural movements and interact seamlessly with diverse objects. This capability is particularly critical in sectors like healthcare, where the safe handling of delicate tissues and organs is essential.

Elastomers empower soft robots to maneuver, deform, stretch, and compress, enabling them to navigate complex environments and perform intricate tasks effectively. For example, a soft robot equipped with elastomers could assist in minimally invasive surgeries, where precision and gentle manipulation are imperative. The elasticity provided by these materials ensures that the robots can adapt to the dynamic demands of surgical procedures without causing harm.

Moreover, the application of elastomers in soft robotics paves the way for safer human-robot interactions. In fields such as elder care and child care, soft robots can aid with daily activities without posing a risk of injury, thanks to their pliable nature. Elastomers also endow these robots with dynamic response capabilities and shape-changing properties, making them resilient in challenging conditions.

The Role of Silicones

Silicones play a pivotal role in soft robotics due to their exceptional flexibility, durability, and biocompatibility. These materials are highly resistant to extreme temperatures, chemicals, and UV radiation, making them indispensable for various components such as soft grippers, actuators, and sensors.

Silicones can be engineered with different hardness levels, allowing for customization to meet specific requirements. Whether a soft, stretchy material is needed for delicate operations or a more robust one for demanding tasks, silicones provide the necessary versatility. This adaptability enables the creation of soft robots capable of performing complex, precise movements across diverse tasks and environments.

Key benefits of using silicones in soft robotics include:

- High Stretchability: Facilitates intricate and precise movements.

- Temperature Resistance: Operates effectively in extreme heat or cold.

- Chemical Resistance: Endures exposure to various substances without degradation.

- UV Resistance: Maintains structural integrity under prolonged UV exposure.

- Biocompatibility: Safe for medical and wearable applications.

Navigating Complex Environments

Soft robots excel in navigating complex environments due to their innovative materials and designs, which allow for exceptional flexibility and adaptability. Their ability to deform and adjust their shape enables them to squeeze through tight spaces, traverse uneven terrains, and interact with delicate objects more effectively than rigid robots. These features make them ideal for exploring caves, wreckage, and other challenging environments where traditional robots would struggle.

In unpredictable or hazardous areas, soft robots demonstrate their value through their unique materials and designs. For instance, in a search-and-rescue mission, a rigid robot might get stuck in rubble, but a soft robot can maneuver through debris and reach victims more quickly. Their capacity to conform to changing surroundings makes them indispensable in such scenarios.

Human-Robot Interactions

Navigating through complex environments underscores the versatility of soft robots, but their true potential lies in enhancing human-robot interactions. Soft robots improve safety by offering flexible and impact-absorbing characteristics, making them ideal for tasks that require delicate handling or close human proximity. These robots mimic the flexibility and adaptability of human muscles, fostering more natural interactions.

When interacting with soft robots, you'll observe how effortlessly they deform and conform to various shapes. This capability ensures safe and effective collaboration in a range of settings. The gentle nature of soft robots makes them especially suitable for environments where human safety and comfort are critical.

Key benefits of soft robots in human-robot interactions include:

- Safety: Their flexible structure minimizes the risk of injury during interaction.

- Natural Movement: Mimicking human muscles facilitates more intuitive and fluid movements.

- Adaptability: Ability to conform to different shapes enhances functionality.

- Delicate Handling: Perfect for tasks requiring a gentle touch, such as in medical applications.

- Intuitive Interface: Encourages better collaboration and understanding between humans and robots.

Future Advancements

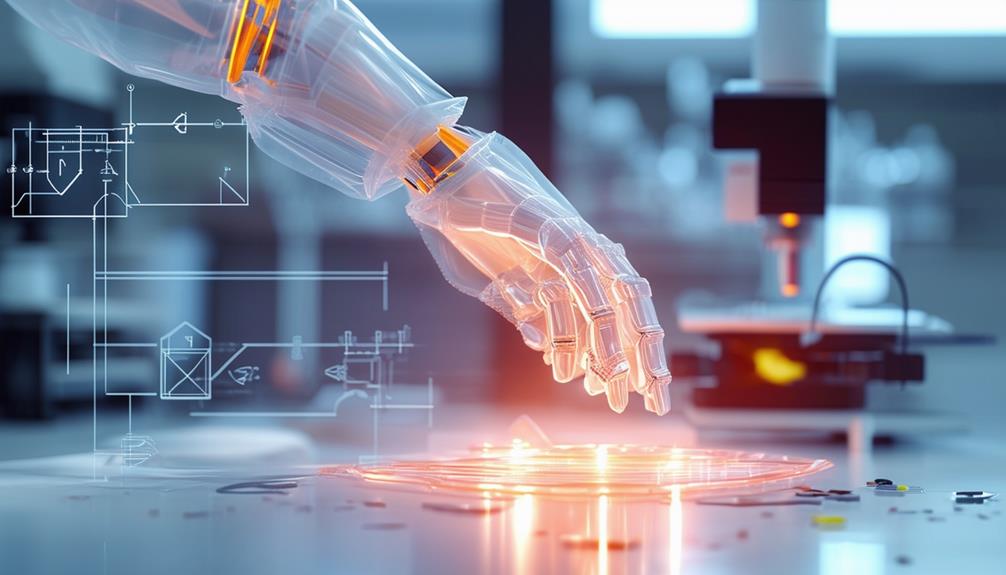

Looking ahead, soft robotics will revolutionize various fields by integrating advanced materials like hydrogels and shape-memory alloys. These materials offer flexibility and adaptability, making them ideal for gentle manipulation tasks. Imagine soft robots traversing complex environments autonomously, thanks to self-organizing capabilities. These robots will adapt and learn, making them invaluable in developmental and evolutionary robotics.

In agriculture, soft robots will perform delicate harvesting tasks, handling fruits and vegetables without causing damage. The gentle manipulation enabled by these advanced materials ensures that crops are picked with care, increasing efficiency and reducing waste. In military operations, soft robotics will enhance reconnaissance missions, maneuvering through tight spaces and providing vital data without detection.

The future also lies in integrating soft and hard robotics, creating systems that are more versatile, resilient, and efficient. Combining the strengths of both, these hybrid robots will excel in a range of applications, from industrial automation to healthcare. As these technologies advance, we will witness a new era where robotics not only mimic but also exceed human capabilities in complex and dynamic environments.

Conclusion

In exploring soft robotics, advanced materials like elastomers and silicones have significantly improved flexibility and durability. These advancements enable robots to navigate complex environments and interact safely with humans. Ongoing developments in materials and design promise a bright future for soft robotics, with revolutionary applications and improvements on the horizon. As the field continues to evolve, the possibilities are endless, and you are part of this incredible journey.