Exploring Soft Robotics: New Materials and Applications

When considering the future of robotics, it's essential to examine the groundbreaking advancements in soft robotics. New materials like hydrogels and elastomers are expanding the possibilities for these robots in medical, industrial, and even space applications. The integration of fibers and shape-memory properties enables these robots to perform complex tasks while maintaining their structural integrity. Additionally, silicone-based materials and innovative fabric integration techniques are pivotal in advancing the field. Curious about how these developments are shaping the industry and what lies ahead? There is still much to explore.

Innovative Soft Robotics Materials

Cutting-edge materials like hydrogels and elastomers are revolutionizing soft robotics by enhancing how robots interact with their environment. Their flexibility and adaptability make them ideal for a wide range of applications. Hydrogels, for instance, offer excellent biocompatibility, making them suitable for medical applications where robots need to interact safely with human tissues. These materials can also change shape and revert to their original form due to their shape-memory properties, allowing robots to perform complex tasks without compromising structural integrity.

Soft actuators, made from elastomers, provide high elasticity, enabling robots to bend, stretch, and compress with ease. This flexibility is crucial for tasks requiring delicate handling or precise movements. The inclusion of fibers in the design further enhances the strength and flexibility of these soft robots, allowing them to withstand various stresses and strains.

Innovative materials are paving the way for advanced functionalities in soft robotics. For example, robots can change color to blend into their surroundings or deliver medication directly to specific areas in the body. These advancements are not just theoretical; they are becoming a reality, thanks to the creative use of materials in soft robotics.

Elastomers in Soft Robotics

Why are elastomers such a game-changer in the field of soft robotics? Elastomers offer unparalleled flexibility and adaptability, which are crucial for the dynamic and evolving needs of soft robotics. These materials, known for their high elasticity, allow soft robots to deform and return to their original shape, making them ideal for maneuvering through diverse environments and performing various tasks.

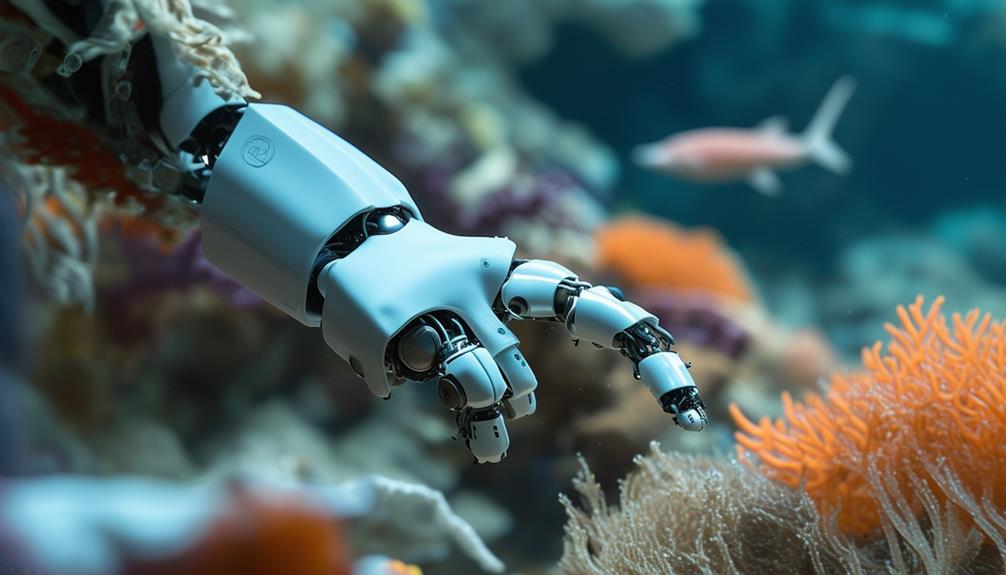

In soft robotics, elastomers are used to create actuators, the components responsible for movement. Soft actuators made from elastomers ensure precise control and efficient motion, enabling robots to perform delicate tasks that rigid robots cannot handle. For instance, a robotic hand designed to gently grip a fragile object without breaking it is feasible thanks to elastomer-based actuators.

Elastomers also play a significant role in developing soft grippers. These grippers can conform to the shape of diverse objects, providing a secure hold without causing damage. This flexibility is essential in applications like medical devices, where gentle handling is paramount, or in industrial settings, where a wide range of objects need to be manipulated.

Silicone-Based Soft Robots

Silicone-based soft robots utilize the flexibility and biocompatibility of silicone to perform precise and versatile tasks across various applications. Constructed with flexible materials, these robots can undergo deformation and shape changes, making them highly adaptable to diverse environments. Silicone's high elasticity and durability ensure these robots can handle repetitive movements and long-term use, making them ideal for wearable technology and medical devices.

In medical research, silicone-based soft robots are transforming drug delivery systems and surgical tools. Their biocompatibility allows them to safely interact with human tissue, minimizing the risk of adverse reactions. For example, these robots can deliver drugs directly to specific body parts, enhancing precision and efficiency. Their ability to conform to the body makes them perfect for wearable technology, offering both comfort and flexibility.

A notable feature of these robots is their integration with shape memory materials, enabling them to change shape in response to external stimuli. This capability enhances their performance in complex tasks like gripping, grasping, and manipulation with exceptional precision. By leveraging advanced materials, silicone-based soft robots are extending the boundaries of robotic capabilities.

Fabric Integration Techniques

To fully understand fabric integration techniques in soft robotics, you will explore advanced weaving methods, intelligent fabric sensors, and textile-based actuators. These innovations allow the development of soft robots that are functional, wearable, and comfortable. By seamlessly integrating technology into fabric, you can revolutionize applications in healthcare, sports, and other fields.

Advanced Weaving Methods

Integrating advanced weaving methods into soft robotics enables the seamless combination of fabric with embedded sensors and actuators, enhancing both functionality and design flexibility. Utilizing these techniques, you can create lightweight and highly adaptable structures. The fabric integration process ensures sensors and actuators are embedded directly within the material, providing a streamlined, versatile solution for various applications.

Advanced weaving methods allow for intricate designs with tailored properties specific to your needs. These scalable techniques facilitate the production of complex soft robotic systems capable of operating effectively in diverse environments. Fabric integration not only enhances the versatility of soft robots but also enables more responsive and adaptive designs, essential for addressing real-world challenges.

Smart Fabric Sensors

Smart fabric sensors are transforming soft robotics by embedding conductive materials directly into textiles, enabling real-time monitoring and adaptability. By incorporating materials like graphene and carbon nanotubes, these sensors enhance the ability of fabrics to precisely track pressure, temperature, and strain. This integration not only improves flexibility and comfort but also paves the way for a variety of wearable applications.

Imagine workout clothes that monitor your muscle activity or a prosthetic limb that adjusts in response to movement patterns. These smart textiles blend seamlessly into everyday items, providing sophisticated data without compromising comfort or usability. Here's a snapshot of their diverse applications:

| Application | Benefits |

|---|---|

| Healthcare | Continuous vital sign monitoring |

| Sports Performance | Real-time muscle activity data |

| Prosthetics | Improved adaptability and comfort |

| Exoskeletons | Enhanced movement coordination |

With advancements in fabric sensor technology, significant improvements are expected in sectors like healthcare, sports, and human-robot interactions. These smart fabric sensors are not just technological marvels; they are practical solutions that enhance the functionality and user experience of wearable robotics.

Textile-based Actuators

Building on advancements in smart fabric sensors, textile-based actuators enhance soft robotics by integrating lightweight and flexible actuation systems into wearable technology. These actuators are essential for developing smart textiles and soft robotic exoskeletons, ensuring comfort, breathability, and adaptability to various body movements.

To effectively integrate actuators into fabrics, techniques such as knitting and weaving are utilized. Knitting creates stretchable and resilient structures, ideal for garments that closely conform to the body's movements. Weaving provides the strength and durability needed for applications like soft robotic exoskeletons. Both methods can incorporate conductive materials, making the fabrics responsive and functional.

Textile-based actuators offer significant potential in healthcare, rehabilitation, and assistive devices. For example, a soft robotic exoskeleton can be woven into a lightweight suit, providing mobility assistance without the bulk of traditional exoskeletons. Similarly, knitted actuators can be integrated into compression garments for therapeutic purposes, enhancing their effectiveness. Textile-based actuators thus open new avenues for creating innovative, functional, and comfortable wearable technologies.

Soft Grippers for Precision Tasks

Soft grippers are increasingly popular for precision tasks due to their advanced material properties. These grippers offer exceptional dexterity, making them ideal for handling delicate items without causing damage. Their versatile applications span various industries, including food handling and biomedical fields.

Adaptive Material Properties

Imagine effortlessly picking up a delicate piece of fruit without causing any damage—that's the magic of soft grippers with adaptive material properties. These grippers are engineered to handle delicate and precise tasks using materials such as elastomers, hydrogels, and shape-memory alloys. This unique combination enables the flexibility needed to gently and securely grasp a variety of objects.

Soft grippers excel in tasks necessitating a gentle touch, making them ideal for industries like food packaging and biomedical procedures. Their adaptability allows them to conform to different shapes and sizes, ensuring even the most fragile items are handled with care.

Here are three key benefits of using soft grippers with adaptive material properties:

- Versatility: Their ability to adjust to a range of textures and sizes makes them indispensable for pick-and-place tasks in manufacturing and research settings.

- Flexibility: Materials like elastomers and hydrogels provide the necessary flexibility to grip objects without causing damage.

- Precision: Shape-memory alloys allow the grippers to return to their original form, ensuring consistent performance for repetitive tasks.

Enhanced Dexterity Mechanisms

Soft grippers, made from compliant materials like elastomers, offer unparalleled dexterity by conforming to diverse shapes. This adaptability makes them ideal for handling delicate objects such as fruit or sensitive electronic components, providing a gentle yet firm grip that prevents damage.

The enhanced dexterity of soft grippers is due to their ability to adjust to various shapes and sizes, unlike rigid grippers. This versatility makes them suitable for precision tasks in diverse environments. Their compliance also allows for safe interaction with humans and sensitive surroundings, minimizing the risk of injury or damage.

In tasks requiring intricate movements, soft grippers outperform traditional grippers. Their conformability and adaptability lead to more effective manipulation, thereby improving efficiency. Whether in a laboratory or industrial setting, soft grippers enhance the precision and safety of operations. Their combination of compliant materials and adaptability makes them invaluable in any context requiring enhanced dexterity.

Versatile Application Fields

Soft grippers' versatility in handling various shapes and sizes makes them invaluable across multiple industries, especially for tasks requiring precision and care. Utilizing materials like silicone, these grippers offer exceptional flexibility and adaptability, making them ideal for handling delicate items in sectors such as food processing and electronics assembly. NASA's research centers have explored these grippers for space missions, where the gentle touch of soft materials can prevent damage to sensitive equipment.

In the realm of soft robotics, soft grippers present significant advantages over traditional rigid grippers. They enhance efficiency and safety, particularly for tasks that necessitate fine motor skills and precise control, such as pick-and-place operations. Unlike traditional grippers that often require complex adjustments and can cause damage, soft grippers seamlessly conform to the shape and size of the object they are handling.

Here are three key application fields where soft grippers excel:

- Food Industry: Handling fragile produce without causing bruising.

- Electronics Assembly: Precisely placing components without inflicting damage.

- Medical Field: Gently manipulating tissues during surgical procedures.

Soft Robotics in Space

In the vast expanse of space, soft robotics are revolutionizing tasks such as in-space assembly and habitation on other planetary bodies. NASA is leveraging soft robots to transform how space missions are conducted. These innovations are integrated into astronaut suits to improve dexterity, making it easier to grip and manipulate objects. This not only assists astronauts in lifting heavy equipment but also guarantees safe human-robot interaction, which is vital in the unforgiving environment of space.

Imagine soft grippers in space applications bonding and de-bonding struts as effortlessly as LEGO blocks. This capability streamlines in-space assembly, reducing the time and effort required to build structures in orbit or on other celestial bodies. The adaptability of soft robotics means they can perform a variety of tasks, from simple repairs to complex construction projects, alongside astronauts.

Moreover, the versatility of soft robots enhances the safety and efficiency of space missions. They can operate in tight spaces and withstand harsh conditions, making them invaluable for long-duration missions. As we consider the possibilities, it's evident that soft robotics are not just tools but indispensable companions for future space exploration.

Future Applications and Trends

As space missions increasingly leverage soft robotics, the technology's future applications and trends promise groundbreaking advancements across numerous fields on Earth. NASA's progress in soft robotics is catalyzing research and leading to innovative solutions in agriculture, healthcare, and military applications. These robots, with their unique materials and self-organization capabilities, are poised to revolutionize various sectors.

In agriculture, soft robots are already showcasing efficiency and precision in tasks such as harvesting, which could significantly enhance farming operations. The military is also investigating the use of these robots for their adaptability and resilience, aiming to improve agility, reconnaissance, and operational efficiency in challenging environments.

Additionally, the integration of soft and hard robotics is enhancing manipulation, dexterity, versatility, and resilience across multiple applications. This synergy is generating more robust and adaptable solutions for complex tasks.

Here are three exciting future trends in soft robotics:

- Advanced Materials: Development of materials that dynamically respond to stimuli, such as electric fields.

- Adaptation Capabilities: Robots that can self-organize and adapt to specific tasks.

- Evolutionary Robotics: Innovations enabling robots to evolve and improve over time.

The future of soft robotics is indeed promising and full of potential!

Conclusion

Soft robotics is evolving with cutting-edge materials such as hydrogels, elastomers, and silicone. These innovations make robots more flexible, adaptable, and biocompatible, making them ideal for medical, industrial, and space applications. By integrating fibers and shape-memory properties, these robots can perform complex tasks efficiently. As technology advances, expect even more precise and versatile applications. The future of soft robotics is incredibly exciting and full of possibilities.